Method for realizing near-net-shape forming of ceramic structure by laser beam

A near-net-shape, laser beam technology, used in laser welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of affecting the service life of ceramic structures, obvious crack defects, accompanied by defects, etc., to reduce the probability of crack defects. , the effect of reducing the subsequent processing steps and reducing the temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

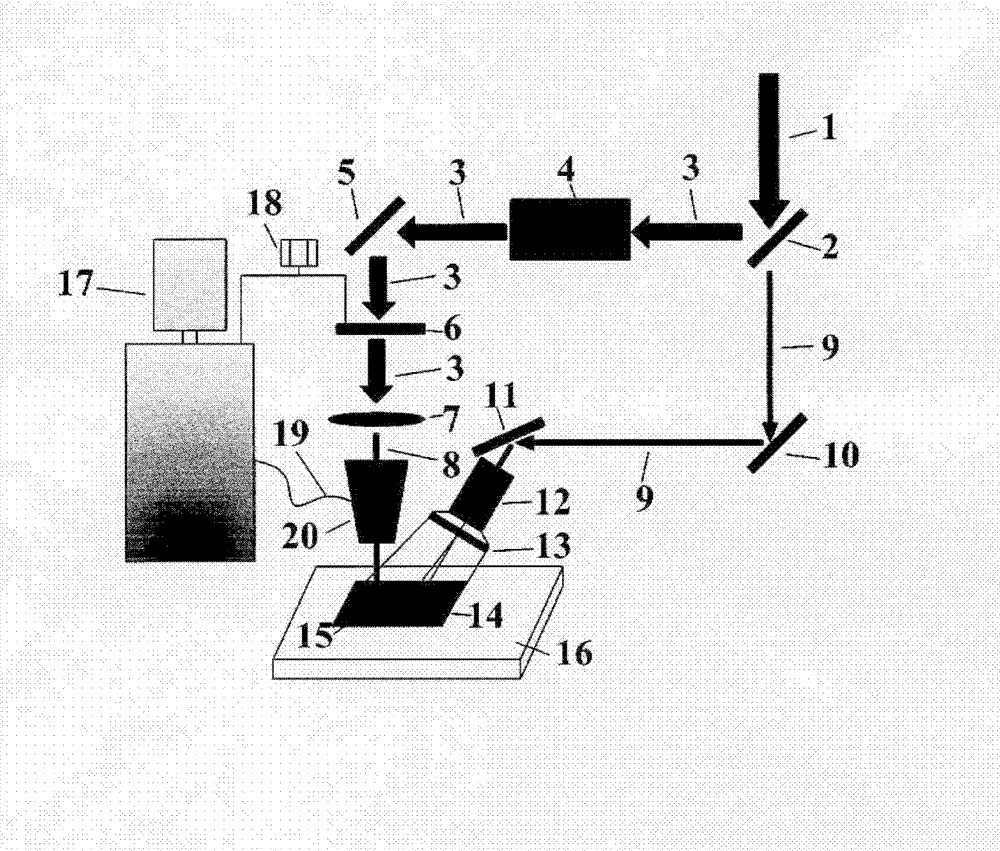

[0022] The present invention will be further described below in conjunction with the accompanying drawings. As shown in Figure 1, the working process of the present invention is as follows:

[0023] The laser beam 1 of the Nd:YAG laser is divided into the main beam 3 and the auxiliary beam 9 by the beam splitter 2, and the ratio of the power of the main beam 3 to the power of the auxiliary beam 9 ranges from 0.1 to 0.9.

[0024] The main beam sequentially passes through the beam expander and beam correction system 4, the total reflection mirror A5, the optical switch 6, the focusing lens 7 and the coaxial nozzle 20 to reach the surface of the substrate 16, and the optical switch 6 and the powder feeding system 17 are realized through the synchronous control unit 18 Synchronously, the powder feeding system 17 sends the ceramic powder to the coaxial nozzle 20 through the powder feeding pipeline 19, heats and melts the ceramic powder under the action of the main beam 8 after focu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com