Preparation method and use method of dimethoate molecule imprinted polymer (MIP)

A technology of molecular imprinting and polymers, applied in material excitation analysis, fluorescence/phosphorescence, etc., can solve the problems of complex preparation process and poor accuracy, and achieve good selectivity, high sensitivity and accuracy, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, a kind of preparation method of dimethoate molecularly imprinted polymer, comprises the following steps successively:

[0037] 1), using dimethoate as a template molecule, acrylamide as a functional monomer for polymerization, ethylene glycol dimethacrylate (EDMGA) as a crosslinking agent, chloroform as a porogen, and azobisiso Nitrile (AIBN) was used as the initiator.

[0038] Weigh 1.0 mmol of dimethoate and add it into a glass test tube containing 10 mL of chloroform, then add 4.0 mmol of acrylamide, and place the above reaction solution in a high-power (frequency range: 50 kHz) ultrasonic cleaner for ultrasonic treatment for 1 hour. So that the dimethoate molecule is fully combined with acrylamide, then add 40mmol of ethylene glycol dimethacrylate (EDMGA) as a cross-linking agent and 65mg of azobisisobutyronitrile (AIBN), then ultrasonically treat for 10 minutes at the same frequency minutes; a mixture was obtained.

[0039] 2) Put the above-mentione...

Embodiment 2

[0043]Example 2, the pretreatment of the analysis sample by the molecularly imprinted polymer of Delo fruit and the use of calcein-Pd 2+ For fluorescent probe detection dimethoate content, carry out the following steps successively:

[0044] 1) Accurately weigh 5.00 g of powdered tea samples into a 25 mL stoppered test tube, add 10 mL of methanol, mix well and ultrasonically (ultrasonic frequency is 40-60 kHz) at 40°C for 20 minutes; after standing for 10 minutes, Obtain the first supernatant, then centrifuge the first supernatant at 4000r / min for 5 minutes to obtain the second supernatant, and transfer the second supernatant into a 25mL stoppered test tube.

[0045] 2) Add 20 mg of dimethoate molecularly imprinted polymer (obtained in Example 1) to the above-mentioned secondary supernatant, and perform isothermal adsorption for 60 minutes in a 40° C. water bath thermostat. Centrifuge at a speed of 4000r / min for 5 minutes, discard the supernatant, and obtain a precipitate. T...

Embodiment 3

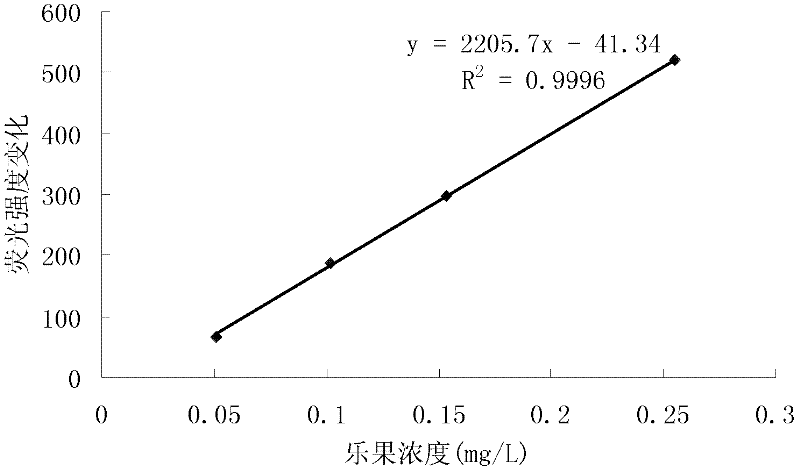

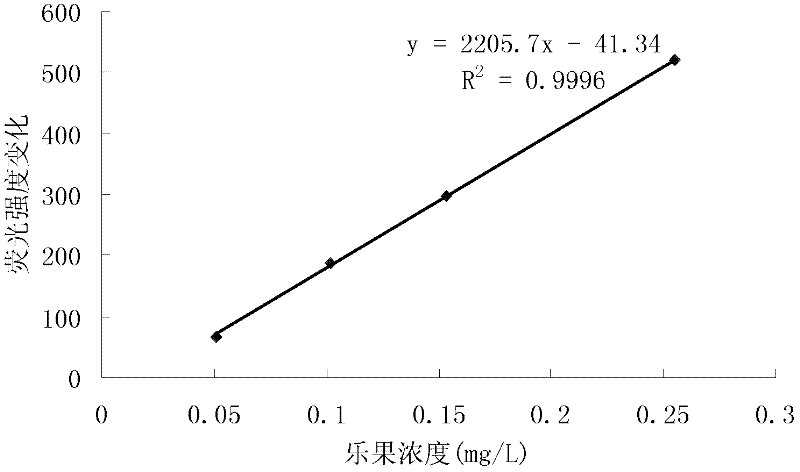

[0050] Embodiment 3, change the tea sample in embodiment 2 into another kind of tea sample, all the other are the same as embodiment 2; The obtained fluorescence intensity value is 75.94, 75.94-2.58=73.36, and 73.36 is substituted into formula y=2205.7x as y value In -41.34, get x=0.052mg / L; This is the dimethoate content in the solution after the test product is constant volume.

[0051] Since the solution to be tested has 10ml after constant volume, and the tea sample is 5.00g, the content of dimethoate in the tea sample obtained after conversion is 0.104mg / kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com