Thermoplastic elastomer capable of coating and bonding with glass fibre filling reinforced nylon

A thermoplastic elastomer, nylon technology, applied in the field of thermoplastic elastomer and its preparation, can solve the problems of poor physical properties, reduced bonding effect, small application range, etc., achieves good mechanical properties and use properties, simple preparation method, and process short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Elastomer A1 was prepared as follows:

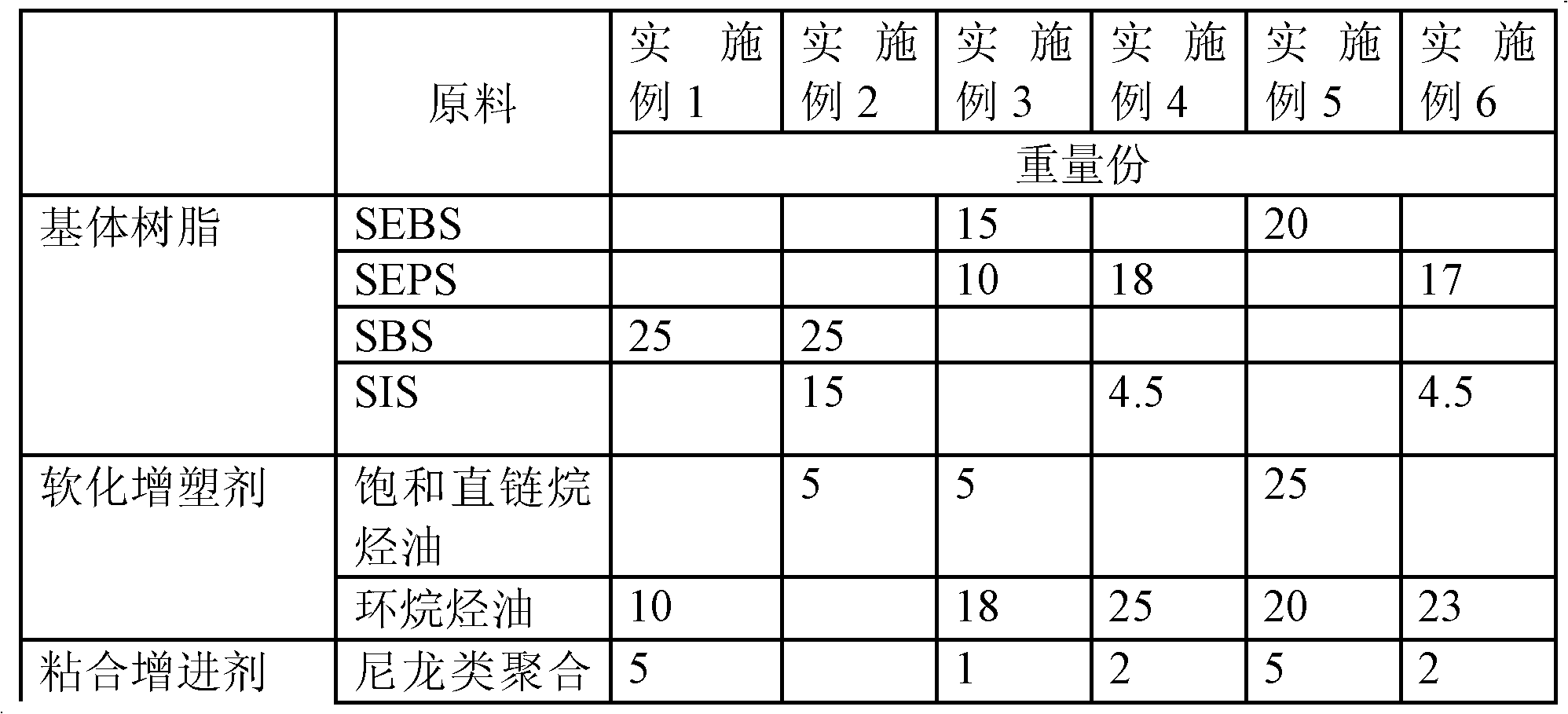

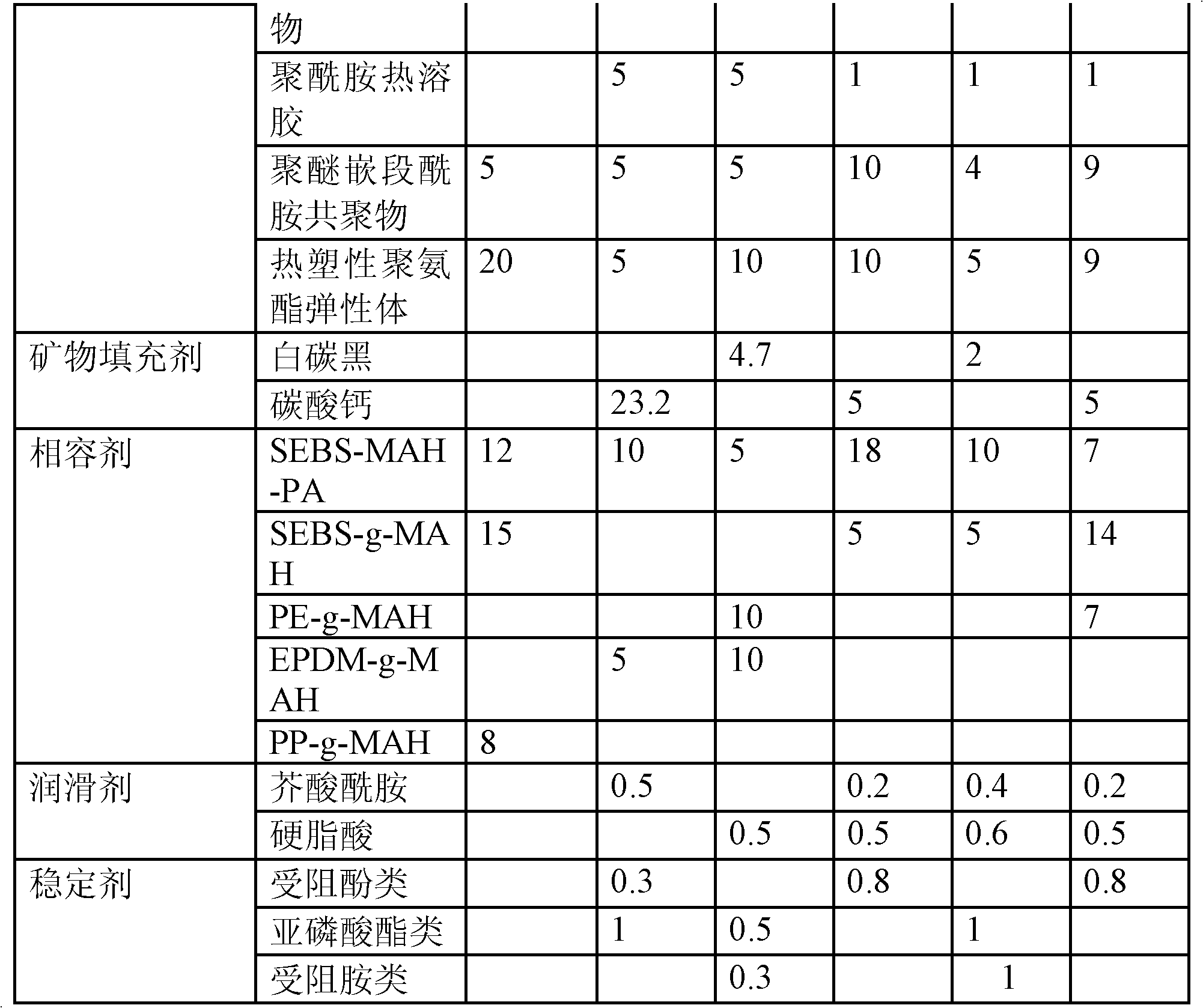

[0039] 1. Take raw materials according to the weight percentage distribution ratio of Example 1 in Table 1;

[0040] 2. Put the matrix resin into the mixer, inject the softening plasticizer into the mixer through the spray device, spray and mix while spraying;

[0041] 3. After the softening plasticizer is completely absorbed by the matrix resin, add adhesion promoters, compatibilizers, mineral fillers, stabilizers, and lubricants and mix well;

[0042] 4. Put the mixed materials above into a twin-screw extruder to extrude and granulate. The temperature of the twin-screw extruder is set at 250°C, the feeding frequency is 20 Hz, and the speed of the main machine is 300 rpm.

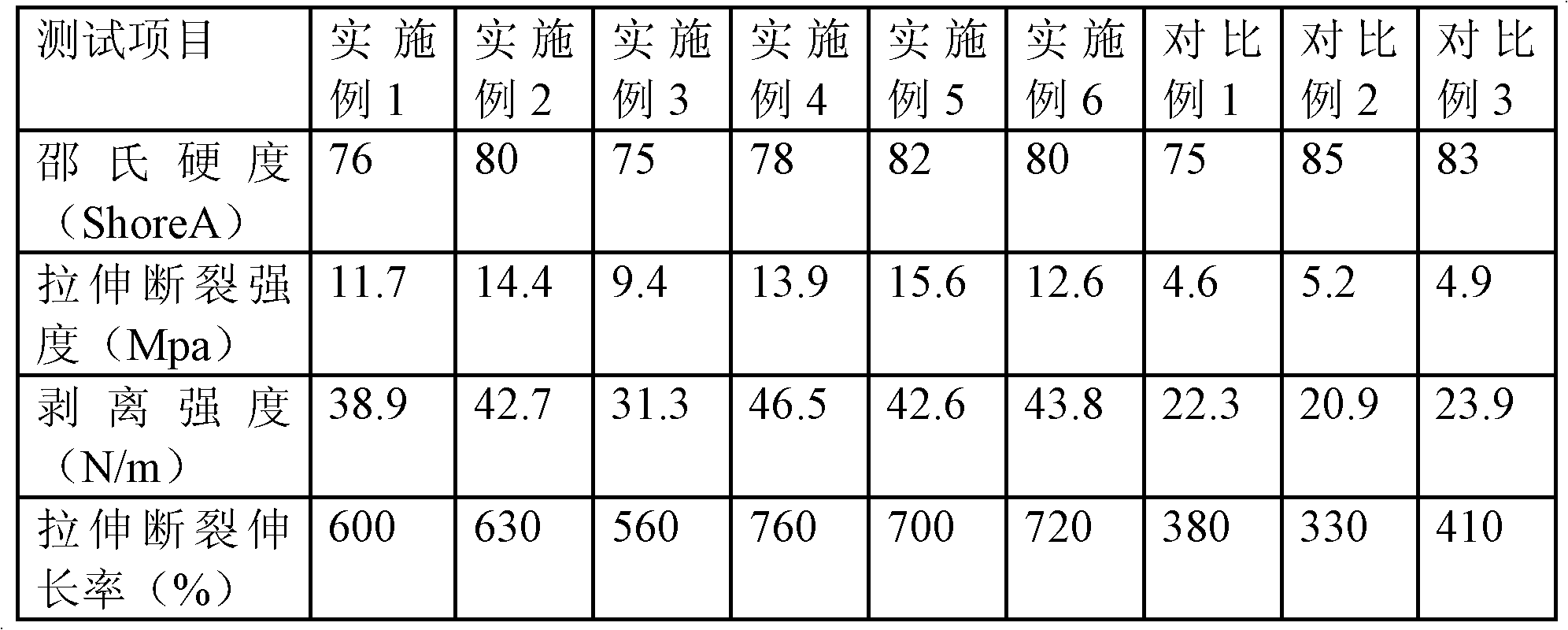

[0043] Thermoplastic elastomer and high glass fiber filled nylon (25% glass fiber content) including bonding: uniformly spray a surface treatment agent on the predetermined bonding surface of nylon, and then complete the secondary injection molding process wi...

Embodiment 2-6

[0058] Elastomers A2-A6 and samples B2-B6 were prepared according to the method of Example 1 and the raw materials of Examples 2-6 in Table 1 and their percentages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com