Differential testing method of power density distribution of electron beam

A technology of electron beam current and power density, which is applied in the direction of radiation measurement, measuring device, X/γ/cosmic radiation measurement, etc. It can solve the problems of affecting measurement accuracy, large measurement error, and easy blocking of small holes by metal, and achieves The effect of improving measurement accuracy and saving test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

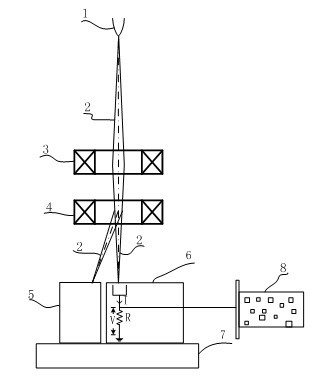

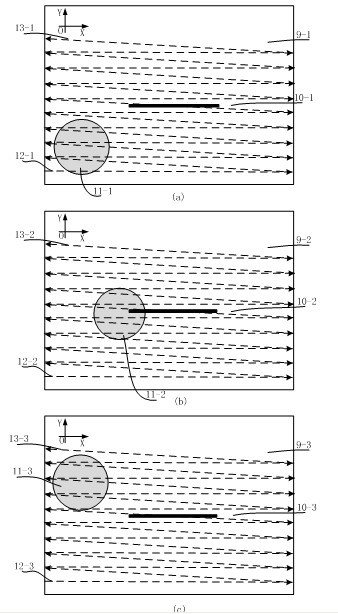

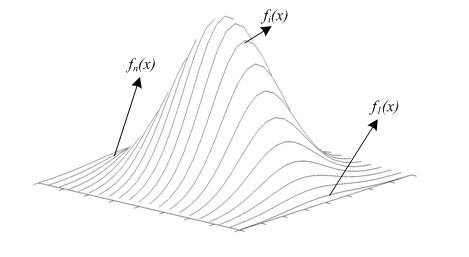

[0021] combine figure 1 , the differential test method of electron beam current power density distribution of the present invention, the steps are as follows:

[0022] 1.1 Layout of the test system. The test system includes an electron beam welder, an energy absorbing device 5, a Faraday cage sensor 6, and an industrial computer. The electron beam welder includes an electron beam emitting cathode 1, a focusing coil 3, a deflection coil 4, a workbench 7 and Welding machine control system, the electron beam current 2 is generated by the electron beam emitting cathode 1 in the electron gun, the focusing coil 3 and the deflection coil 4 are coaxial, the focusing coil 3 is above the deflection coil 4, the energy absorbing device 5 and the Faraday cup sensor 6 are installed on On the workbench 7, the Faraday cage sensor device 6 is located directly below the deflection coil 4 of the electron beam welder, the energy absorbing device 5 is placed on the left side of the Faraday cage s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com