Fluorescence lens, manufacturing method thereof and white-light lighting lamp manufactured by using fluorescence lens

A lighting and lens technology, applied in the field of white light lighting, can solve the problems of inaccurate proportioning, difficult uniformity control, increased production cost, etc., and achieves the effect of good light uniformity, avoiding repeated waste, and reducing investment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

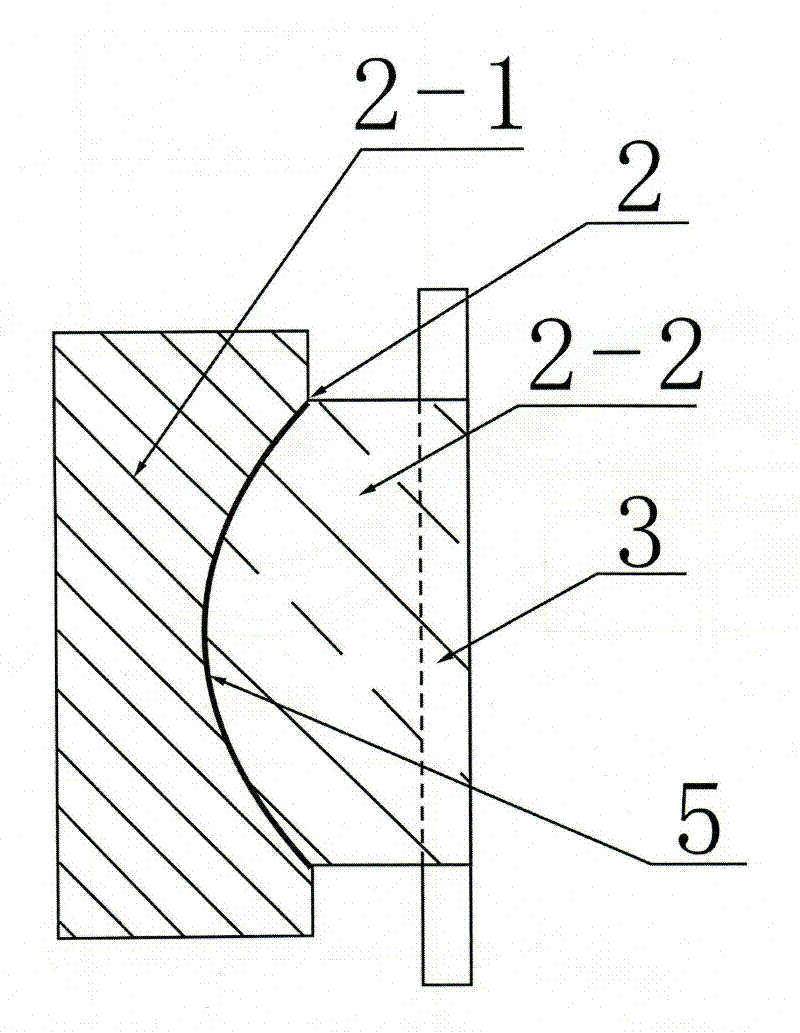

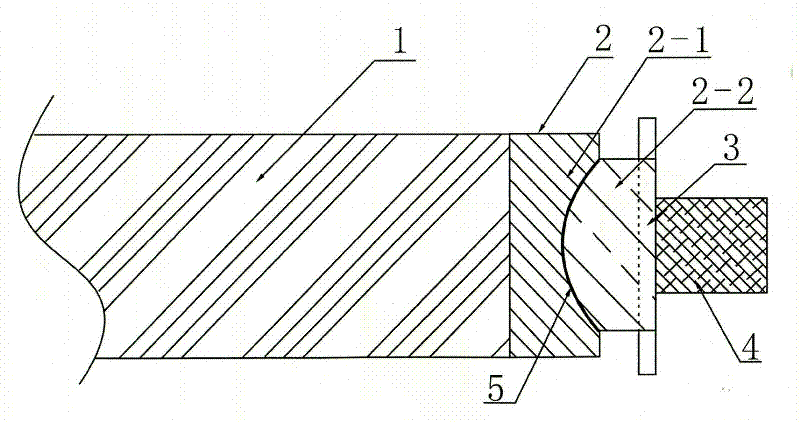

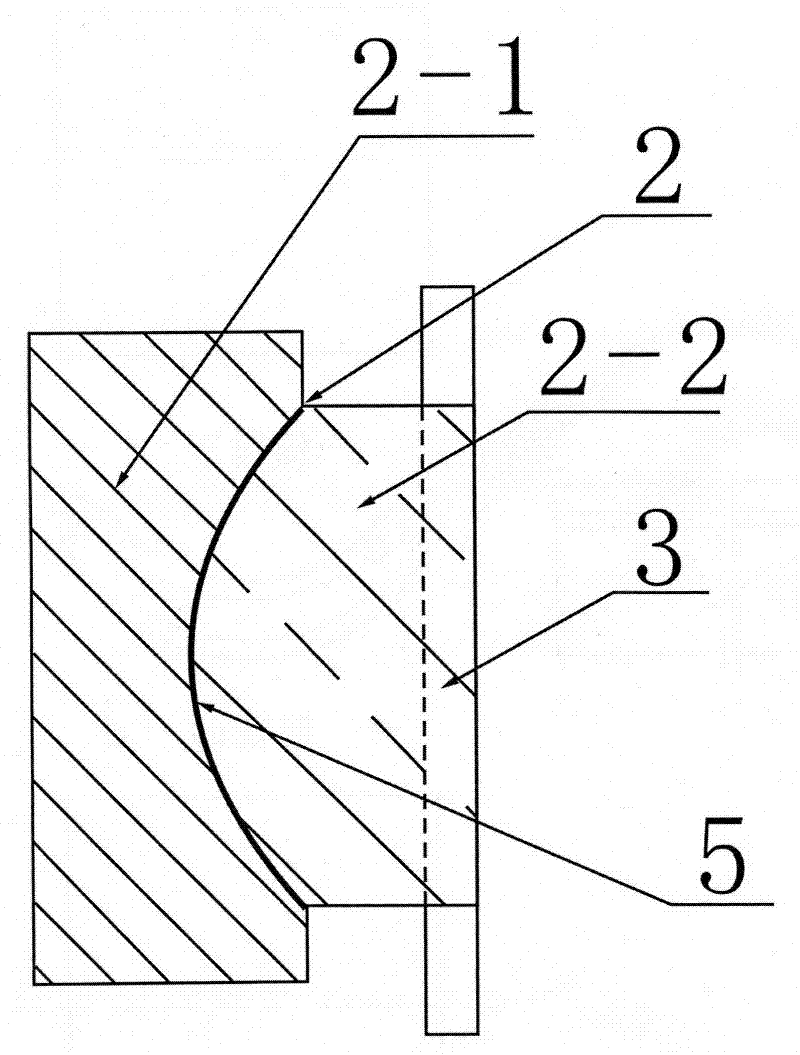

[0023] A fluorescent lens 2 is composed of a concave lens 2-1, a convex lens 2-2 and a phosphor layer 5 on the surface of the convex lens 2-2, see figure 1 shown. Both ends of the lens 2 are flat surfaces, and a yellow and / or green and / or red and / or blue phosphor layer 5 is vapor-deposited or sputtered or dispensed on the surface of the convex lens 2-2.

Embodiment 2

[0025] The method steps of manufacturing above-mentioned fluorescent lens 2 are:

[0026] (1) With the help of optical simulation software, input the optical characteristics of the laser diode chip or light-emitting diode chip, such as half-value angle, power, light type, and the reflectivity, refractive index, loss rate, and light transmittance of the matched optical fiber, for comprehensive Simulation, after repeated verification, the optical parameters of the fluorescent lens suitable for matching with the fiber are obtained;

[0027] (2) Make high-precision optical-grade mold cores based on the optical parameters obtained by optical simulation. Firstly, use CNC machine tools to cut the shape of the mold cores, and then make high-precision optical-grade mold cores after grinding and polishing;

[0028] (3) Assemble high-precision optical-grade mold cores and mold bases to form optical-grade injection compression molding molds, and load them on electric injection molding mac...

Embodiment 3

[0031] The first method to cover the convex lens surface of the plastic lens with a phosphor layer is dispensing:

[0032] Configure different ratios of phosphor powder and transparent encapsulant, the ratio range in parts by weight is transparent encapsulant: yellow phosphor: red phosphor: green phosphor: blue phosphor = (1—2.5): (0.1 —2.5): (0.01—2.5): (0.02—2.5): (0.03—2.5), use a dispenser to point the prepared phosphor glue onto the convex lens surface in the lens, adjust the color temperature and dry it , which becomes the fluorescent lens 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com