Preparation technology of porphyra haitanensis phycobiliprotein powder

The technology of phycobiliprotein and seaweed is applied in the field of preparation of seaweed phycobili protein powder, and can solve the problems of complicated separation and purification method of phycobiliprotein, high production cost and inability to prepare in large quantities and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

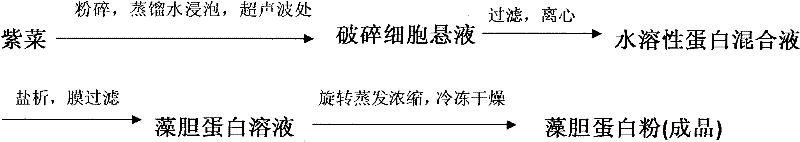

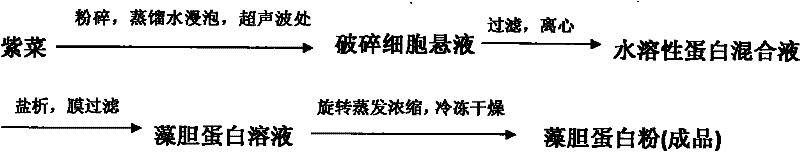

[0017] The present invention uses algae laver as raw material to prepare altar laver phycobiliprotein powder, and the preparation steps of the invention are as follows:

[0018] 1. Altar laver cell crushing process

[0019] The laver is first pulverized with a pulverizer, then the pulverized laver powder is soaked in water for 5-10 hours, the soaked material is taken out, and pulverized with ultrasonic waves.

[0020] 2. Preparation of phycobiliprotein crude extract

[0021] Soak the algae cells directly with distilled water or low-salt solution to make them swell, rupture, and release phycobiliproteins. It takes 10 days to soak in distilled water, and 3 to 4 days to soak in low-salt solution.

[0022] Weigh 5.99g laver powder, soak in distilled water, and fully swell. After 12 days, filter with a 74-micron filter cloth, and centrifuge the filtrate at 5500 g for 20 min at 4°C to remove algae residues, and take the purple-red supernatant as the crude phycobiliprotein extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com