Colorful pavement cementing material for low-grade road surface and preparation method of colorful pavement cementing material

A low-grade, glue-laying technology, applied in the field of low-grade pavement color paving cement and its preparation, to achieve the effects of improving monotony, improving performance and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

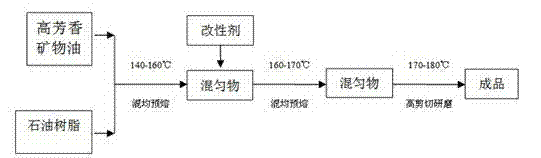

Method used

Image

Examples

Embodiment 1

[0052] (1) 1610 kg of highly aromatic mineral oil (including 170 kg of catalytic oil slurry) is placed in the reaction kettle, and the temperature is raised to 140-160 ° C;

[0053] (2) Add 1320 kilograms of petroleum resin, stir and mix for 30 minutes;

[0054] (3) Heat the reactor to 170°C, add 250 kg of modifier, and stir and mix for 40 minutes;

[0055] (4) Heat the mixture in the reaction kettle to 170°C for grinding. The shearing speed of the grinding machine is 2500 rpm, and the shearing time is 20 minutes. Grind twice to obtain the color shop cement.

[0056] The petroleum resin is C9 petroleum resin with a softening point of 100-120°C. It is a thermoplastic resin with a molecular weight of 300-3000 oligomers. It has low acid value, good miscibility, water resistance, ethanol resistance and resistance Chemicals and other properties, it is chemically stable to acid and alkali, and has the characteristics of good viscosity adjustment and thermal stability, and plays the...

Embodiment 2

[0060] (1) Put 1480 kg of highly aromatic mineral oil (including 160 kg of catalytic oil slurry) in the reaction kettle, and heat up to 160°C;

[0061] (2) Add 1430 kilograms of petroleum resin, stir and mix for 20 minutes;

[0062] (3) Heat the reaction kettle to 160°C, add 280 kg of modifier, and stir and mix for 60 minutes;

[0063] (4) Heat the homogeneous mixture in the reactor to 180°C, carry out the grinding operation, the shearing speed is 2000 rpm, the shearing time is 30 minutes, and the color shop cement is obtained by grinding twice.

[0064] The petroleum resin is C9 petroleum resin with a softening point of 100-120°C. It is a thermoplastic resin with a molecular weight of 300-3000 oligomers. It has low acid value, good miscibility, water resistance, ethanol resistance and resistance Chemicals and other properties, it is chemically stable to acid and alkali, and has the characteristics of good viscosity adjustment and thermal stability, and plays the role of thic...

Embodiment 3

[0068] (1) 1520 kg of highly aromatic mineral oil (180 kg of catalytic oil slurry) is placed in the reaction kettle, heated to 150°C;

[0069] (2) Add 1400 kilograms of petroleum resin, stir and mix for 25 minutes;

[0070] (3) Heat the reaction kettle to 165°C, add 240 kg of modifier, and stir and mix for 50 minutes;

[0071] (4) Heat the homogeneous mixture in the reactor to 175°C, carry out the grinding operation, the shearing speed is 3000 rpm, the shearing time is 10 minutes, and the color shop cement is obtained by grinding twice.

[0072] The petroleum resin is C9 petroleum resin with a softening point of 100-120°C. It is a thermoplastic resin with a molecular weight of 300-3000 oligomers. It has low acid value, good miscibility, water resistance, ethanol resistance and resistance Chemicals and other properties, it is chemically stable to acid and alkali, and has the characteristics of good viscosity adjustment and thermal stability, and plays the role of thickening an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com