Intelligent winch type pulling oil production system

An oil production system, winch-type technology, applied in hoisting devices, production fluids, earthwork drilling and production, etc., can solve the problem of manual control of pumping unit start-up and shut-down time is difficult to grasp, start-up and shut-down time stuck wells and operations Problems such as rework and the complex structure of the beam pumping unit have achieved the effect of reducing wear and tear on the bottom of the inner layer, facilitating collection and negative pressure unblocking, and simple and reliable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

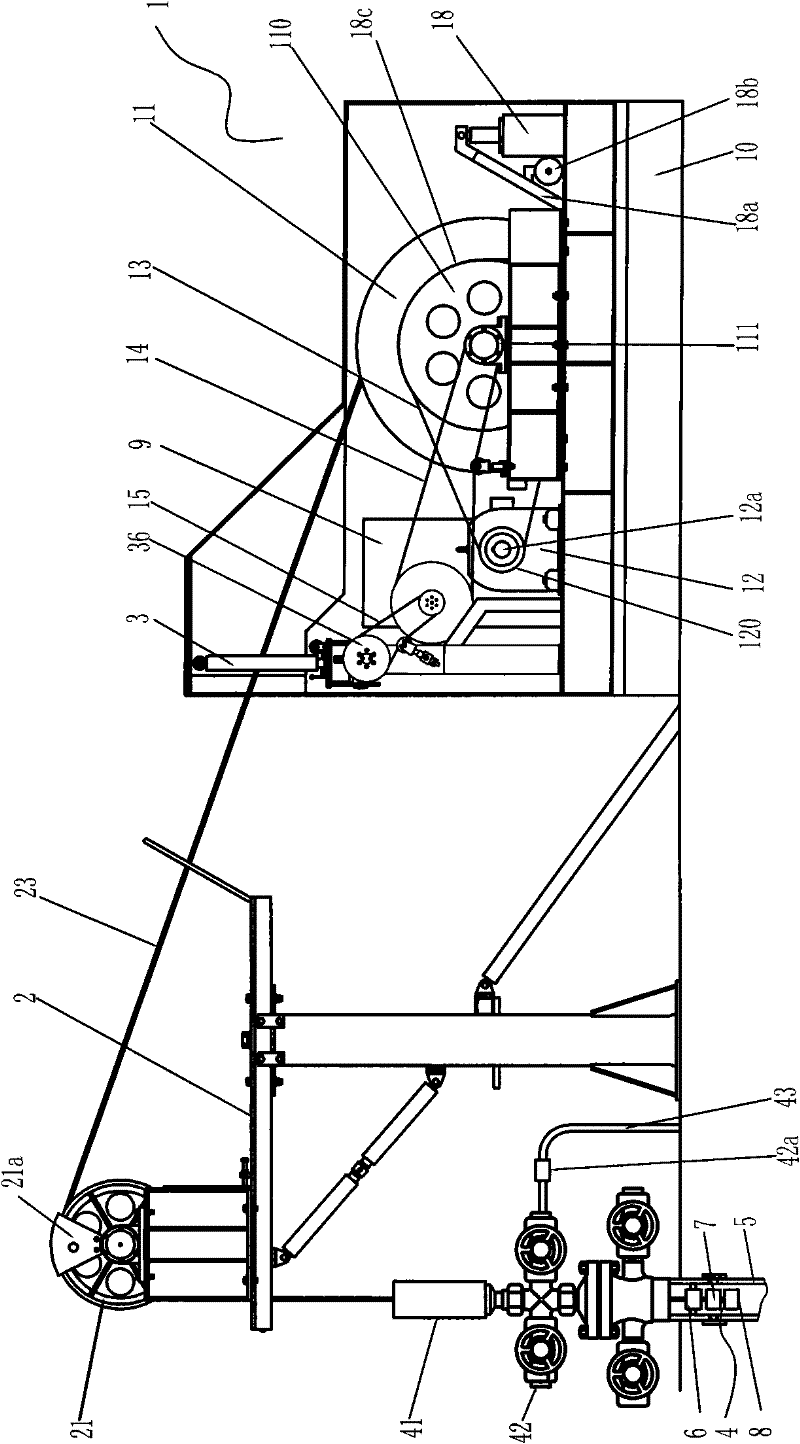

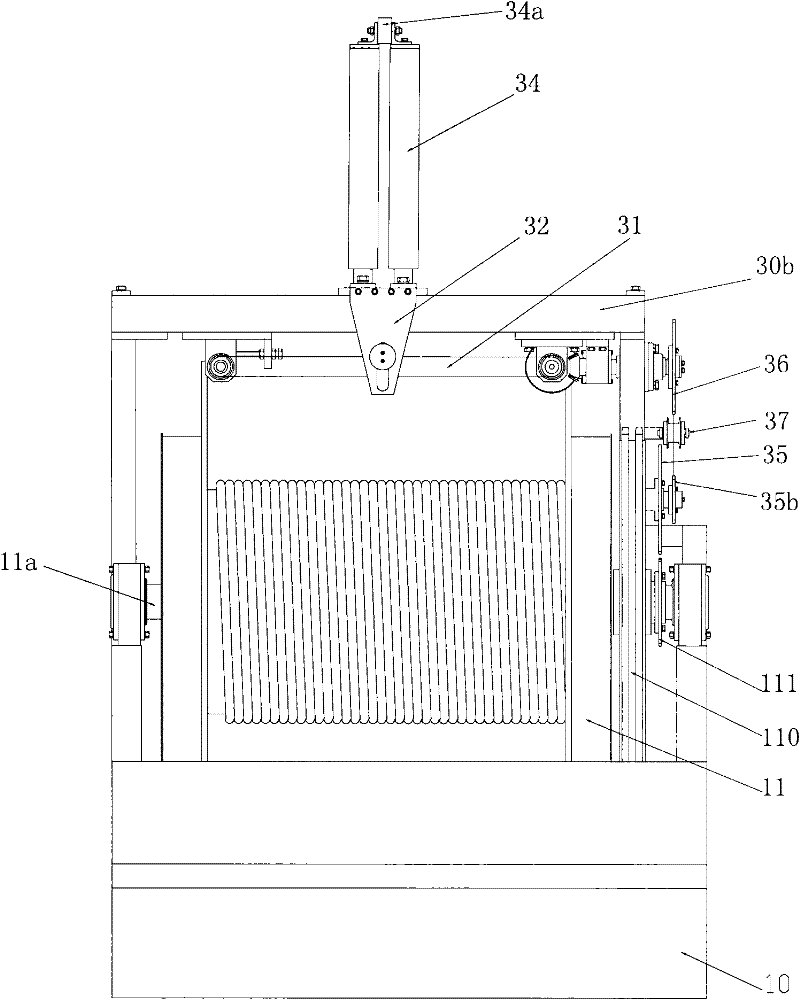

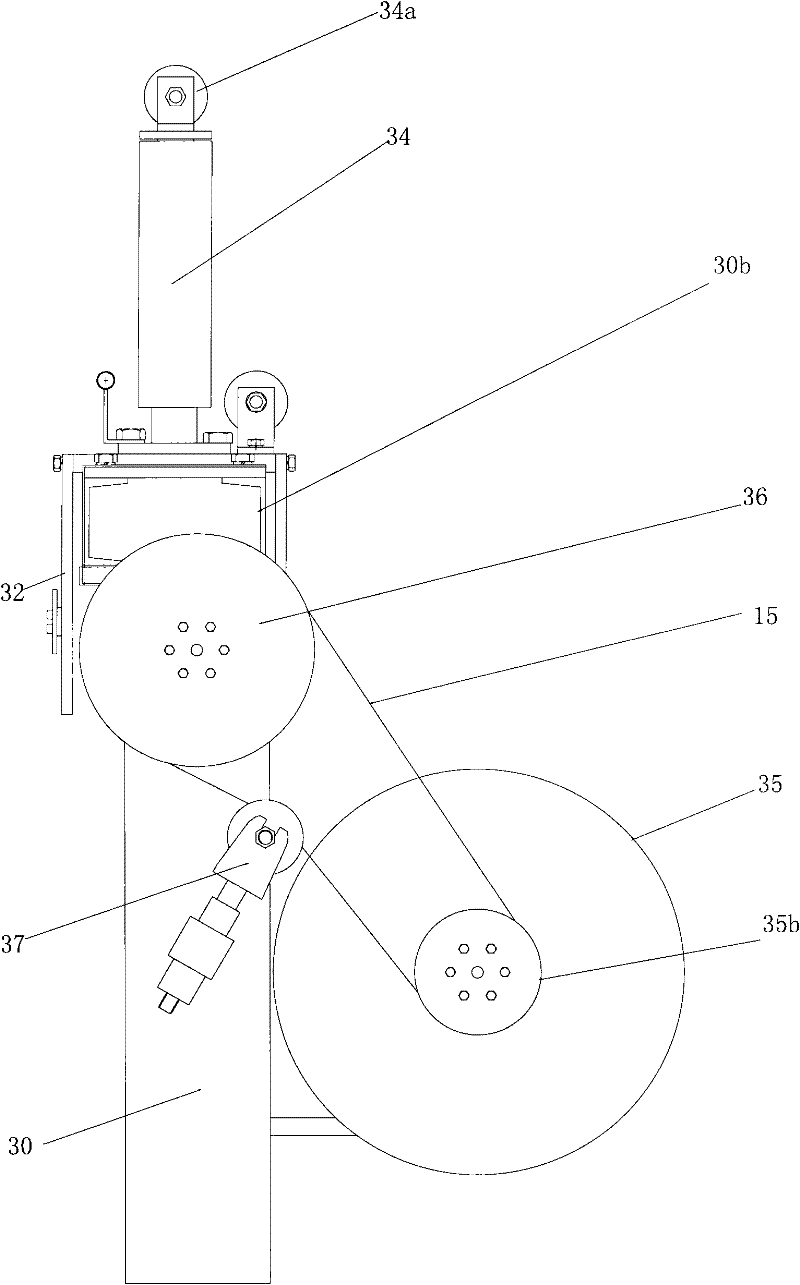

[0048] Such as figure 1 As shown in the schematic diagram of the overall structure of the intelligent hoisting type oil production system of the present invention, the intelligent hoisting type oil production system of the present invention includes: a drive assembly 1 arranged on the ground base 10, with a motor for winding the oil rope The reel 11 of 23 and the motor 12 that drives the reel 11 to rotate; The frame 2 installed on the ground is equipped with a pulley 21; The oil production device 4 is arranged in the downhole oil well string 5; Wrapped on the reel 11, the other end goes around the pulley 21 on the frame 2 to connect with the oil production device 4; the control device 9 is used to control the rotation of the motor 12 to drive the reel 11 to rotate, thereby driving the oil production through the oil extraction rope 3 Device 4 is used for extraction and recovery operations. Wherein, the oil production device 4 is provided with a downhole liquid column height de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com