Four-axis synchronous powerful vibration excitation device used for automatic block moulding machine

A technology of automatic forming and vibration excitation device, which is applied in the direction of ceramic forming machines, auxiliary forming equipment, manufacturing tools, etc., can solve problems such as long time difference between excitation and driving, high amplitude deviation of vibration table surface, lack of effective adjustment and control means, etc. To achieve the effect of solving the large speed difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

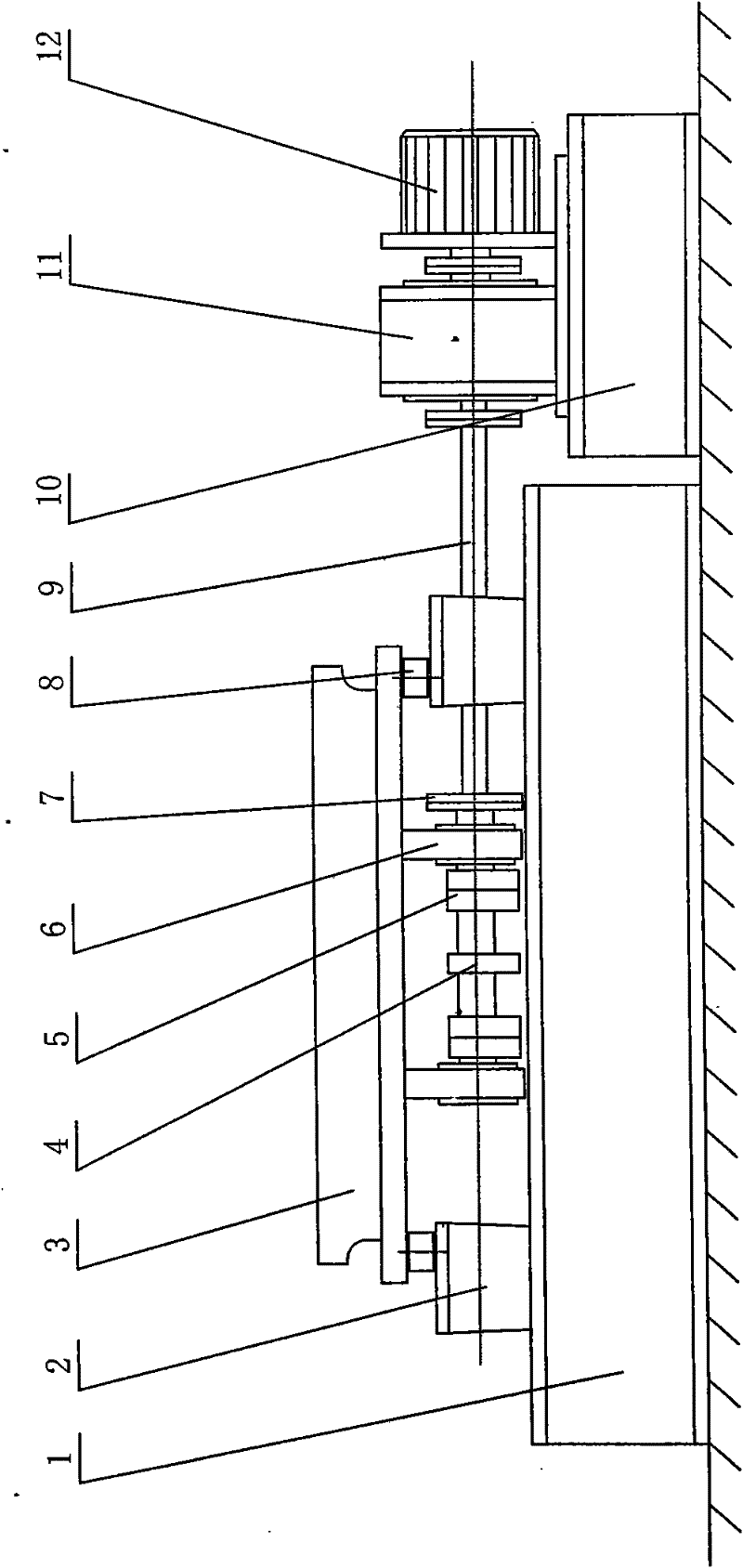

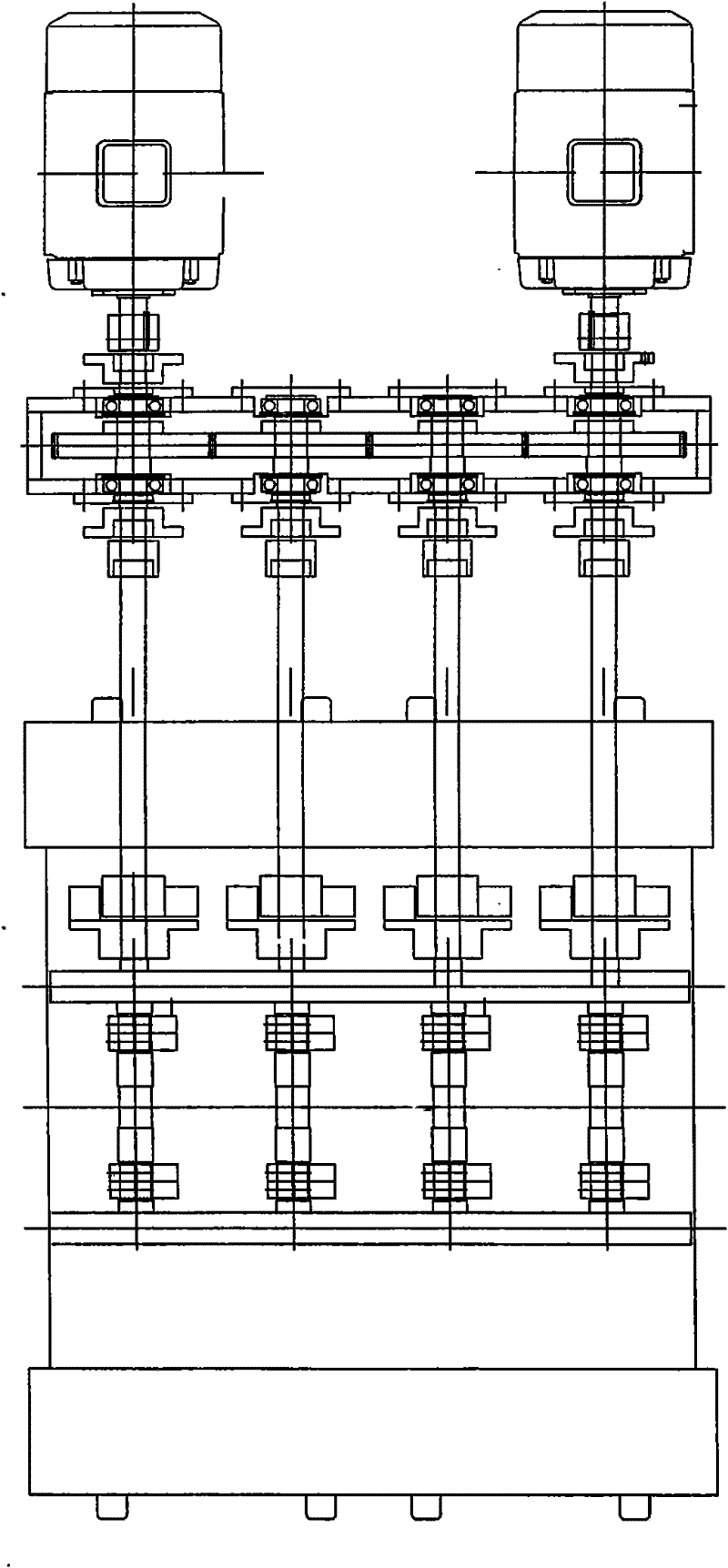

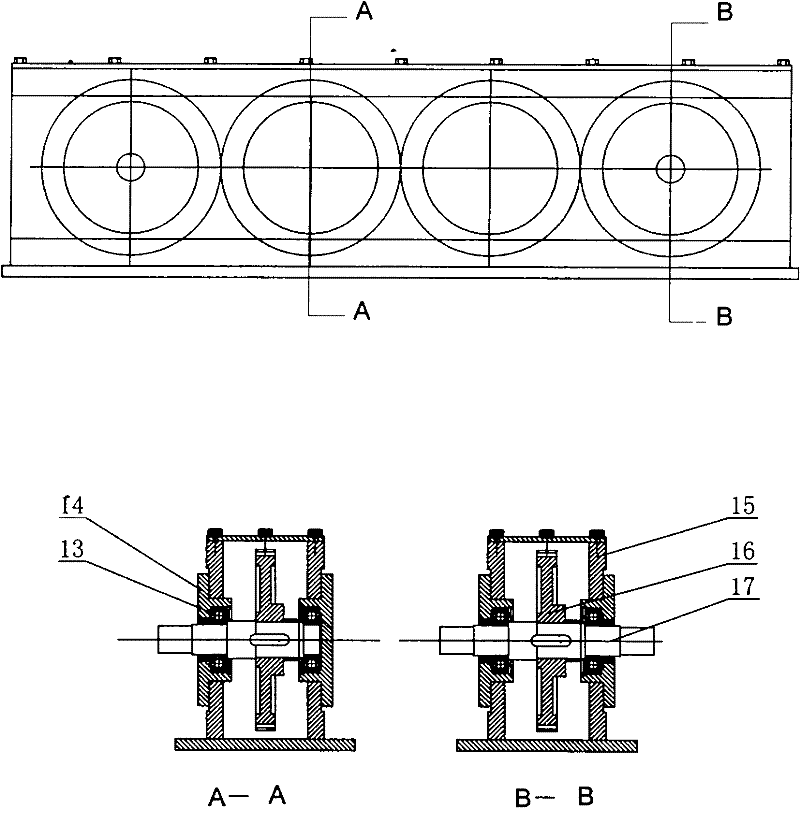

[0030] as attached figure 1 As shown, the four-axis synchronous strong vibration device for the block automatic forming machine of the present invention includes a frequency modulation vibration motor (12), a synchronous gearbox (11), a hard rubber fiber coupling (7), a power transmission shaft (9 ), a vibrator (4), a box-type vibrating table (3), a hard rubber fiber damping block (8), a fixed base (10), and a program-controlled device for automatic frequency adjustment.

[0031] as attached figure 1 , attached figure 2 As shown, the four-axis synchronous strong vibration device for the block automatic forming machine of the present invention selects and uses two 37kw high-power frequency modulation vibration motors (12) as power sources, and the power output shafts of the two frequency modulation vibration motors (12) are The hard rubber fiber couplings (7) are respectively connected to the power input ends of the two synchronous gear shafts (17) in the synchronous gearbox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com