Method for extracting ellagic acid from pomegranate peels

An extraction method and pomegranate peel technology are applied in the field of extraction of effective components of traditional Chinese medicine, can solve the problems of low conversion rate, complicated technical operation, long extraction time and the like, and achieve the effects of increased yield, simple process, increased content and extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

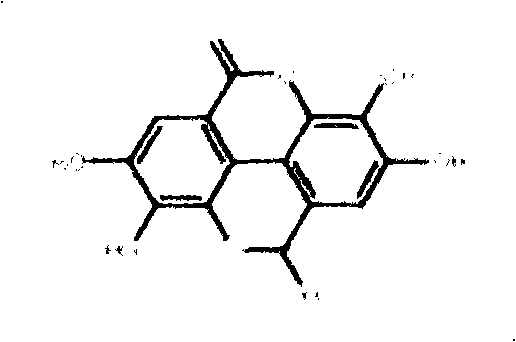

Image

Examples

Embodiment 1

[0027] Processing of raw materials; charcoal frying: Remove the impurities, wash, slice, and dry the original pomegranate peel medicinal material in a hot pot at 300°C until the skin is dark brown and the inside is burnt brown, and slice it for later use.

[0028] Slicing was made into sheets with a thickness of 2 mm.

[0029] Extraction: In terms of mass, add 3 times of tap water to the treated raw material, soak at room temperature for 3 hours, then heat the mixture of the two to 90°C, keep it warm for 2 hours, two times in a row, take the liquid from the filter residue, and then add 8 times of 80% acetone was extracted at 80°C, and the combined filtrates were concentrated.

[0030] In terms of mass, the ratio of the specific gravity of the extracted concentrated solution to the raw material is 1:1.

[0031] Oxidative dehydrogenation: Hydrogen peroxide is added to the concentrated solution for hydrolysis, the ratio of hydrogen peroxide and extract is 20:1, the time is 30 mi...

Embodiment 2

[0034] Processing of raw materials; charcoal frying: remove impurities, wash, slice, and dry the original pomegranate peel medicinal material in a hot pot at 200°C until the skin is dark brown and the inside is burnt brown, sliced or crushed for later use.

[0035] Pulverize to make raw material powder of about 80 mesh.

[0036] Extraction: In terms of mass, add 3 times the amount of tap water to the treated raw material, soak at room temperature for 6 hours, then heat the mixture of the two to 80°C, keep it warm for 4 hours, 3 times in a row, take the liquid from the filter residue, combine and concentrate.

[0037] In terms of mass, the ratio of the specific gravity of the extracted concentrated solution to the raw material is 1:1.

[0038] Oxidative dehydrogenation: add hydrogen peroxide to the extract for hydrolysis, the ratio of hydrogen peroxide to extract is 20:1, the time is 5 minutes, filter and recover the hydrogen peroxide liquid, concentrate the recovered solutio...

Embodiment 3

[0041] Processing of raw materials; charcoal frying: remove impurities, wash, slice, and dry the raw pomegranate peel medicinal material in a hot pot at 400°C until the skin is dark brown and the inside is burnt brown, sliced or crushed for later use.

[0042] Slicing was made into pieces with a thickness of 1 mm.

[0043] Extraction: In terms of mass, add 10 times the amount of tap water to the treated raw material, soak at room temperature for 0.5 hours, then heat the mixture of the two to 100°C, keep it warm for 4 hours, 4 times in a row, take the liquid from the filter residue, and add it to the filtrate 5 times 80% acetone extraction at 80°C, combined extracts and concentrated,

[0044] In terms of mass, the ratio of the specific gravity of the extracted concentrated solution to the raw material is 1:1.

[0045] Oxidative dehydrogenation: add hydrogen peroxide to the extract for hydrolysis, the ratio of hydrogen peroxide to extract is 20:1, the time is 5 minutes, filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com