Clean viscous acid for acid fracturing of carbonate reservoir

A technology of thickening acid in carbonate reservoirs, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems affecting oil and gas well productivity, uneven liquid, clogged formations, etc., and achieve retardation performance Excellent, easy to flow back, prolonging the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1: The weight percent of each component of the raw material of thickened acid for carbonate rock acid pressing is:

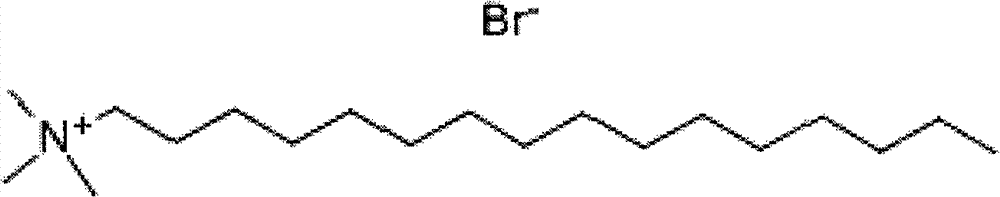

[0079] 1. Hexadecyltrimethylammonium bromide: 3%;

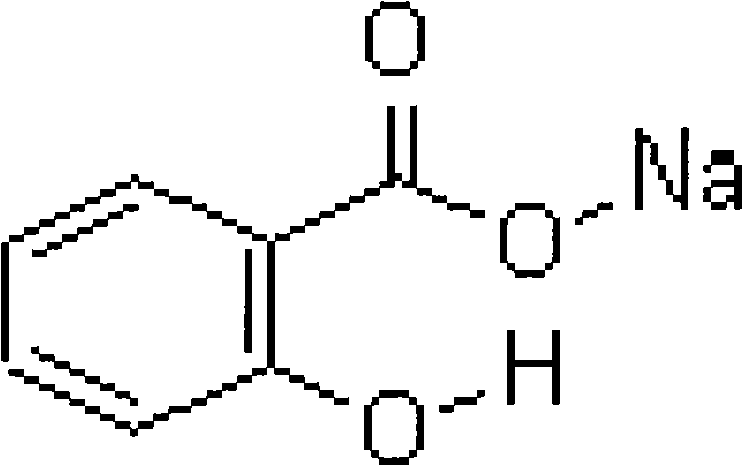

[0080] 2. Sodium o-hydroxybenzoate: 0.3%;

[0081] 3. Hydrochloric acid with a concentration of 38%: 15%;

[0082] 4. Iron ion stabilizer adopts citric acid: 0.15%;

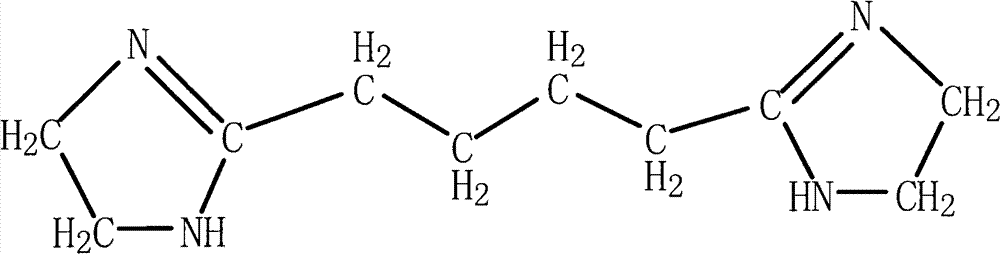

[0083] 5. Bisimidazoline quaternary ammonium salt: 0.2%;

[0084] 6. Tetraethylenepentamine polyoxypropylene polyoxyethylene ether: 0.25%

[0085] 7. N, N-di-sec-butyl-p-phenylenediamine: 0.05%

[0086] 8. The rest is water; the sum of the weight percentages of each component is 100%.

[0087] Preparation method of thickened acid for carbonate rock acid fracturing:

[0088] A. Add water to calculate the required weight in container a;

[0089] B, add sodium o-hydroxybenzoate in container b, get the water preparation concentration in container a and be the sodium o-hydroxybenzoate aqueous solution of 10% for subsequent use;...

Embodiment 2

[0094] Embodiment 2: The weight percent of each component of the raw material of thickened acid for carbonate rock acid pressing is:

[0095] 1. Hexadecyltrimethylammonium bromide (industrial product): 4%;

[0096] 2. Sodium o-hydroxybenzoate (industrial product): 0.4%;

[0097] 3. Hydrochloric acid (industrial product): 20%;

[0098] 4. Iron ion stabilizer adopts CX-301: 0.1%;

[0099] 5. Bisimidazoline quaternary ammonium salt (industrial product): 0.2%;

[0100] 6. Tetraethylenepentamine polyoxypropylene polyoxyethylene ether (industrial product): 0.2%

[0101] 7. N, N-di-sec-butyl-p-phenylenediamine (industrial product): 0.04%

[0102] 8. The rest is water; the sum of the weight percentages of each component is 100%.

[0103] The preparation method is the same as in Example 1, but the weight ratio is different.

[0104] Effect: The retardation rate of thickening acid for carbonate rock acid fracturing reaches 48%. After the core acidification experiment, the core pe...

Embodiment 3

[0105] Embodiment 3: The weight percent of each component of the raw material of thickened acid for carbonate rock acid pressing is:

[0106] 1. Hexadecyltrimethylammonium bromide: 5%;

[0107] 2. Sodium o-hydroxybenzoate: 0.5%;

[0108] 3. Hydrochloric acid: 22%;

[0109] 4. Iron ion stabilizer adopts citric acid: 0.2%;

[0110] 5. Bisimidazoline quaternary ammonium salt: 0.25%;

[0111] 6. Tetraethylenepentamine polyoxypropylene polyoxyethylene ether: 0.1%;

[0112] 7. N, N-di-sec-butyl-p-phenylenediamine: 0.02%;

[0113] 8. The rest is water; the sum of the weight percentages of each component is 100%.

[0114] The preparation method is the same as in Example 1, but the weight ratio is different.

[0115] Effect: The retardation rate of thickened acid for carbonate rock acid fracturing reaches 52%. After the core acidification experiment, the core permeability was increased by 9.6 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com