Welding process of heat-resistant steel cylindrical housing

A welding process, heat-resistant steel technology, applied in the direction of welding equipment, manufacturing tools, arc welding equipment, etc., can solve the problems of welding deformation and welding efficiency, and achieve the effect of solving welding deformation, good quality, and shortening the welding cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in further detail below in conjunction with the example of implementation.

[0035] 1. Structural Design of Cylindrical Case

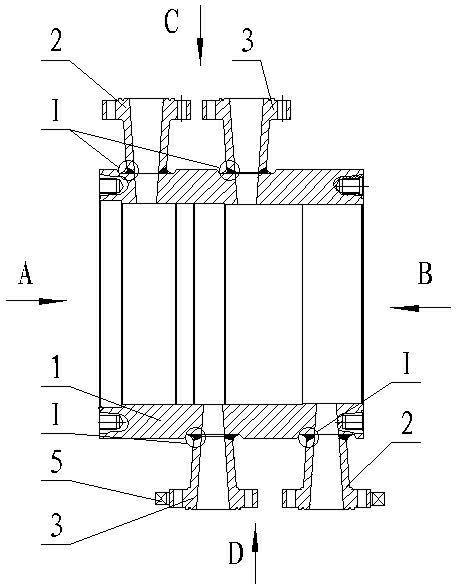

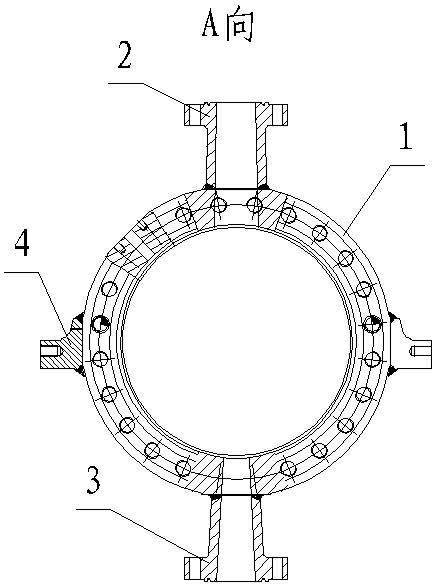

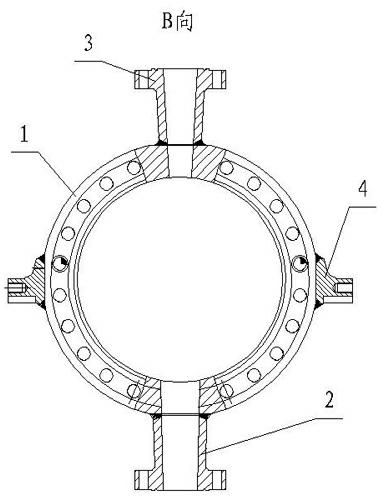

[0036] The cylindrical casing of the compressor is composed of cylinder body 1, inlet flange 2, outlet flange 3, outrigger 4 and guide key 5, wherein inlet flange 2, outlet flange 3, outrigger 4 and guide key 5 are respectively Welded on cylinder 1, such as Figure 1~5 shown.

[0037] 2. Chemical composition, heat treatment and mechanical properties of steel and welding consumables

[0038] The chemical composition and mechanical properties of 20CrMo steel are shown in Table 1 and Table 2.

[0039]

[0040]

[0041] The chemical composition of the welding wire and the mechanical properties of the cladding metal are shown in Table 3 and Table 4.

[0042]

[0043]

[0044] 3. Welding characteristics of 20CrMo heat-resistant steel

[0045] 20CrMo steel is a low-alloy pearlitic heat-resistant ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com