Processing method of inferior residuum

A processing method and residual oil technology, which are applied in the petroleum industry, hydrotreating process, and hydrocarbon oil treatment, etc., can solve the problems of shortened operation period of UFR reactor and low volume of hydrogen oil, so as to avoid the decrease of hydrogenation catalyst activity, The effect of slowing down the rate of ascent and slowing down the rate of inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

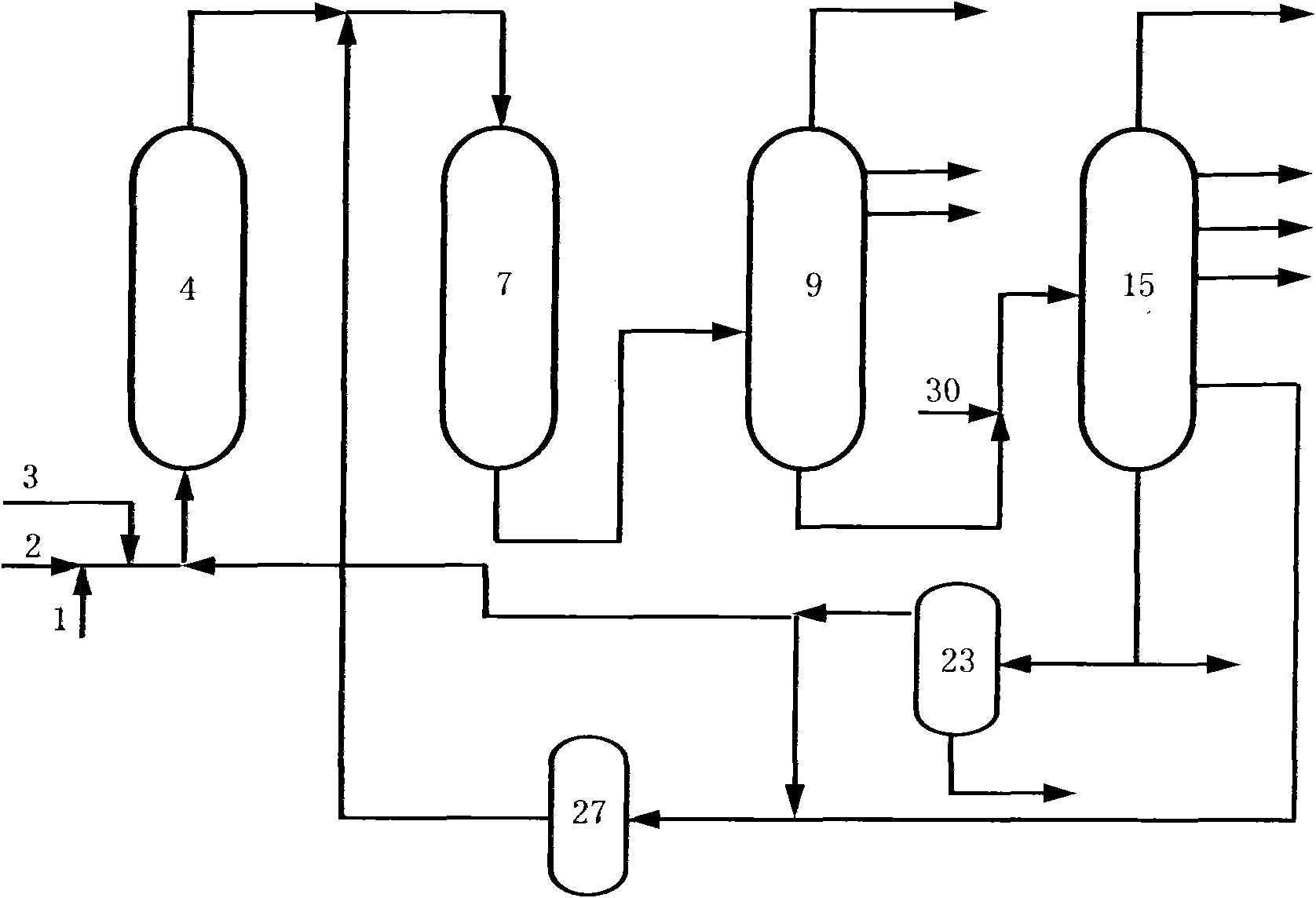

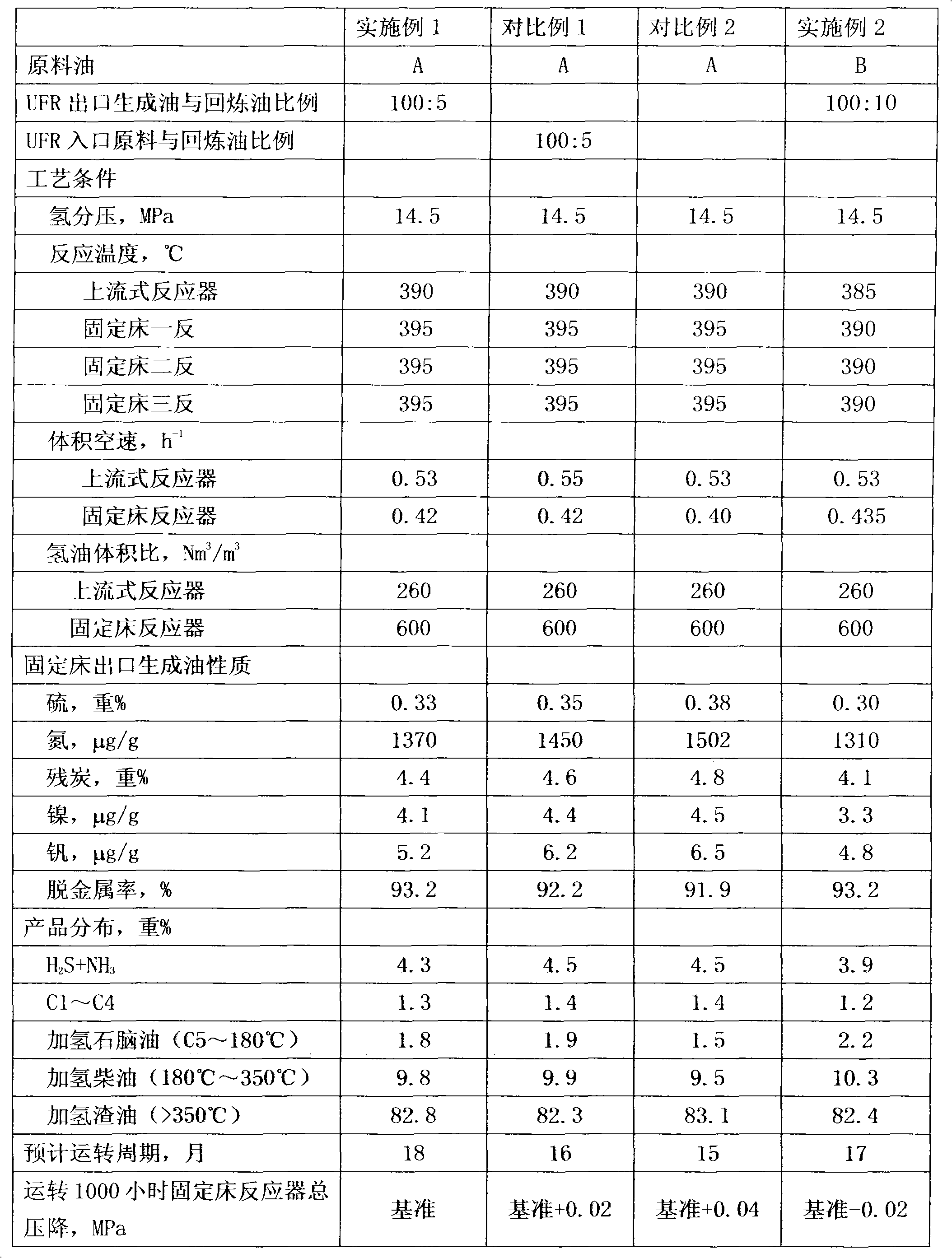

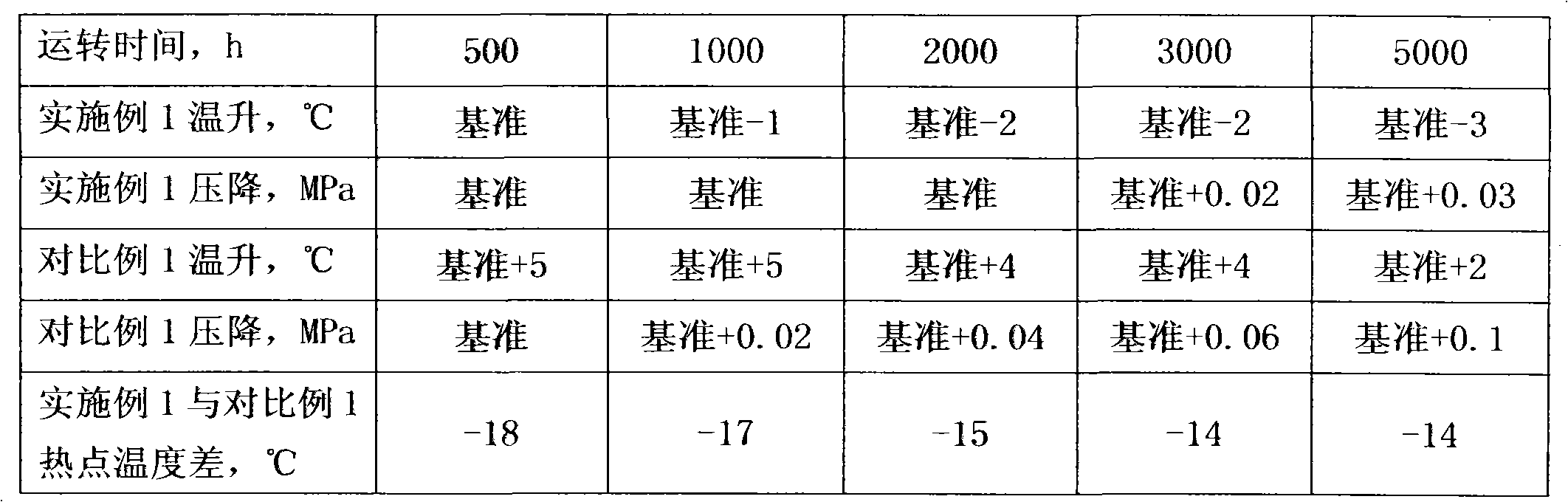

[0053] The residual oil hydrogenation unit of embodiment 1 comprises four reactors, an upflow reactor (UFR) and three fixed bed (trickle bed) reactors, and the upflow reactor catalyst FZC-10UH is filled in the upflow reactor , the first fixed bed reactor (referred to as the first fixed bed reactor) is filled with the protective agent FZC-103 and the demetallization catalyst FZC-28, and the second fixed bed reactor (referred to as the fixed bed second reactor) is filled with the desulfurization catalyst FZC-34A, The third fixed bed reactor (fixed bed three reactors for short) is filled with denitrification catalyst FZC-41A. Wherein, the loading ratio (volume) of upflow reactor catalyst: protective agent: demetallization catalyst: desulfurization catalyst: denitrogenation catalyst is 42:1:12:30:15, that is, the ratio of upflow reactor catalyst to fixed bed reactor catalyst The filling ratio is 42:58.

[0054] The raw material A used in Example 1 is a mixture of vacuum residue, ...

Embodiment 2

[0063] The residual oil hydrogenation unit of embodiment 2 comprises four reactors, an upflow reactor and three fixed bed reactors, the upflow reactor catalyst FZC-10UH is filled in the upflow reactor, and the fixed bed one reversely fills the protective agent FZC-103 and demetallization catalyst FZC-28, fixed-bed two-reverse packing desulfurization catalyst FZC-34A, fixed-bed three-reverse packing denitrogenation catalyst FZC-41A. Wherein the loading ratio of upflow reactor catalyst: protective agent: demetallization catalyst: desulfurization catalyst: denitrogenation catalyst is 34:0.5:9.5:36:20, that is, the loading ratio of upflow reactor catalyst to fixed bed reactor catalyst is 34:66.

[0064] The raw material B used in Example 2 is a mixture of vacuum residue, vacuum gas oil and catalytic cracking slurry distillate, and the mass ratio of the three mixtures is 75:15:10, and its properties are shown in Table 1. The raw material oil B is mixed with hydrogen and enters the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com