Glass paste for forming a photosensitive sealing layer, plasma display manufacturing method using the same, and plasma display

A technology of glass paste and plasma, which is applied in the manufacture of discharge tubes/lamps, exhaust sealing, cold cathode manufacturing, etc., and can solve the problems of forming with good precision without disclosure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~14

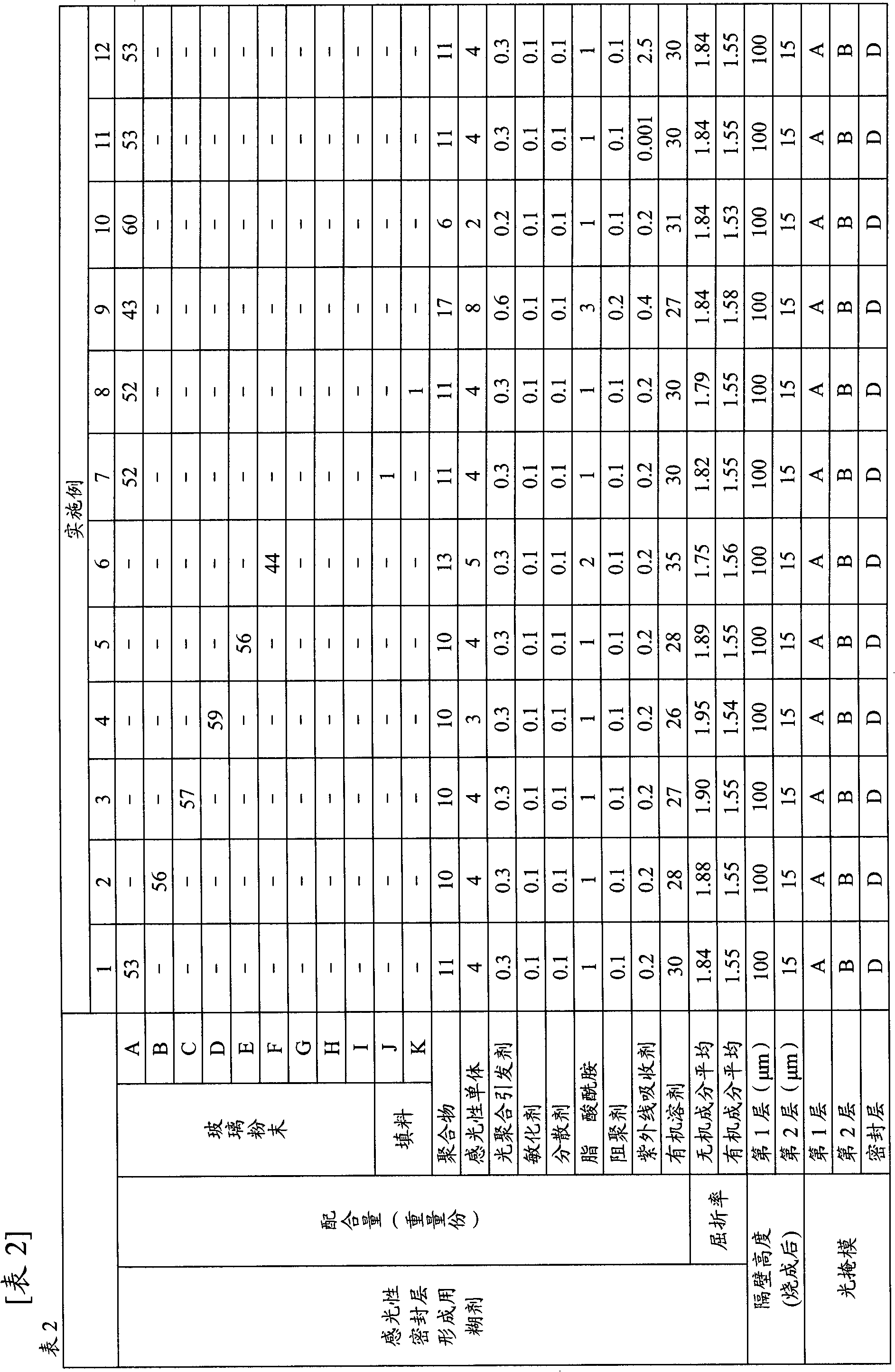

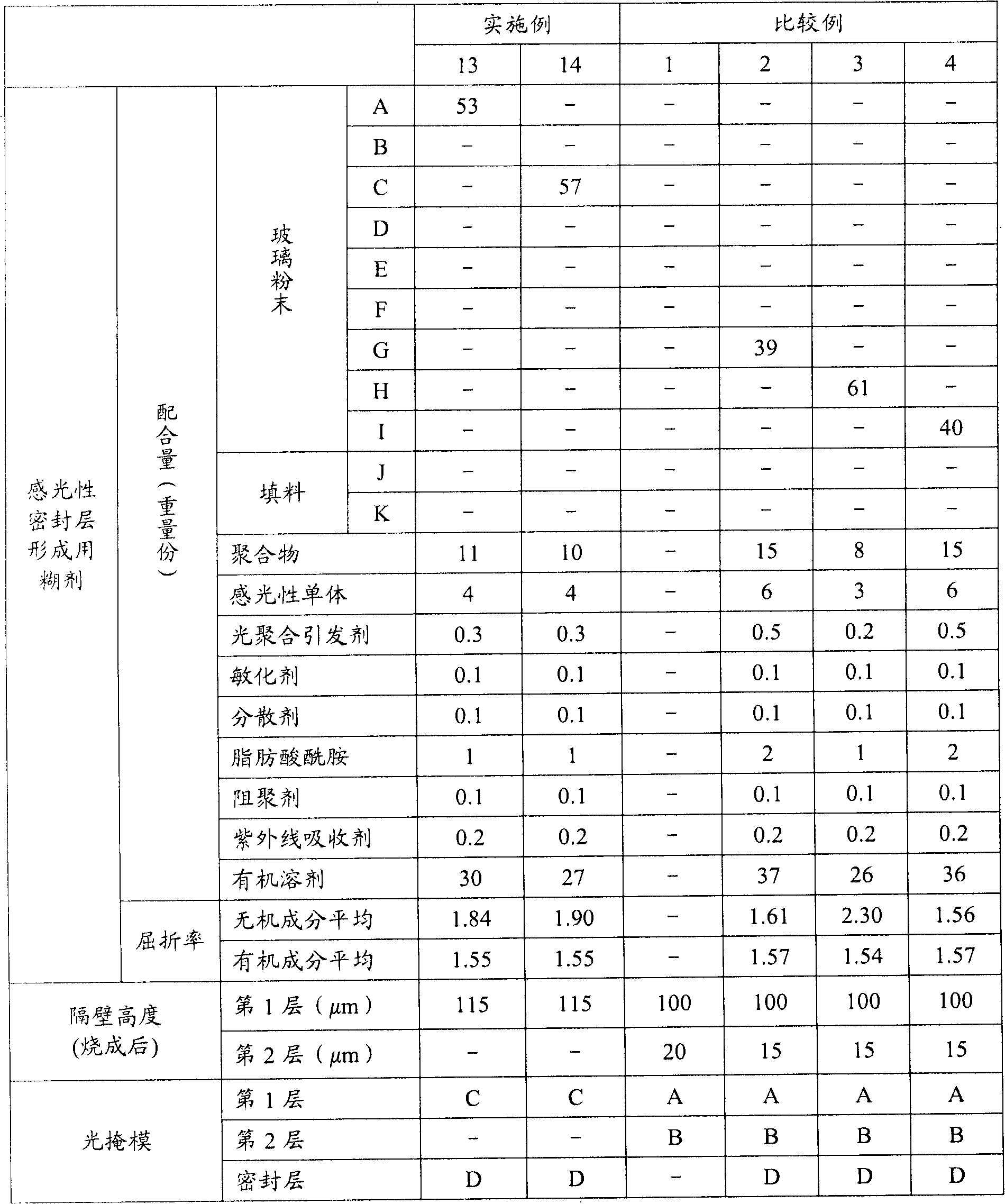

[0106] (Examples 1-14, Comparative Examples 1-4)

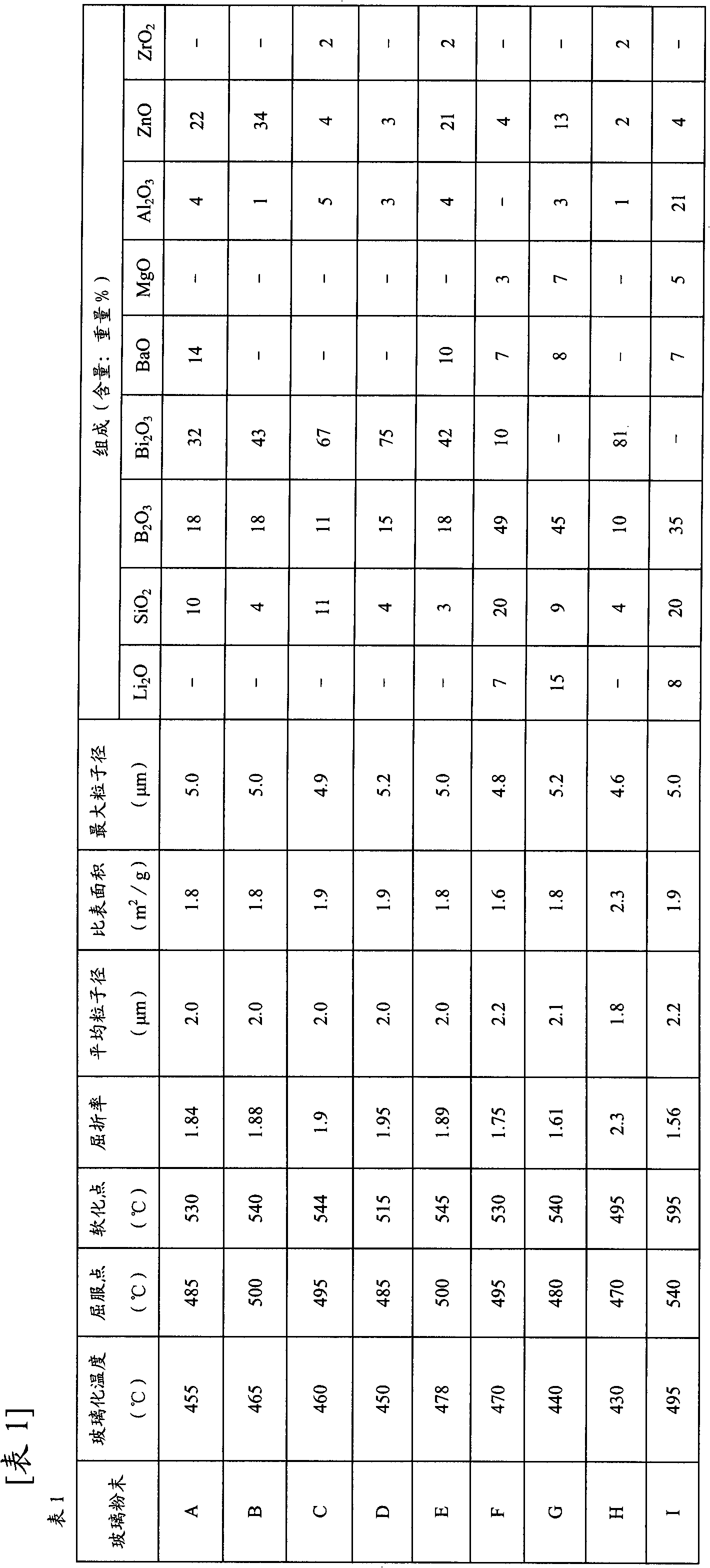

[0107] Table 1 shows the glass powders used in Examples.

[0108]

[0109] In addition, the average particle diameter (D50) and maximum particle diameter (Dmax) of the following glass powder and a filler are the values measured using the Nikkiso Co., Ltd. microtrack particle size distribution analyzer (MT3000). In addition, the glass transition temperature and softening point of the glass powder are the following values: Using the differential thermal analysis method, heating in the air at a heating rate of 10°C / min, the horizontal axis represents the temperature, and the vertical axis represents the heat, and the value read by drawing the DTA curve . The yield point of the glass powder is a value measured by heating in air at a temperature increase rate of 5° C. / min using a thermal dilatometer.

[0110] In addition, the refractive index measurement of a glass powder and a filler was performed using the Becke method, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com