Materials for organic electroluminescent devices

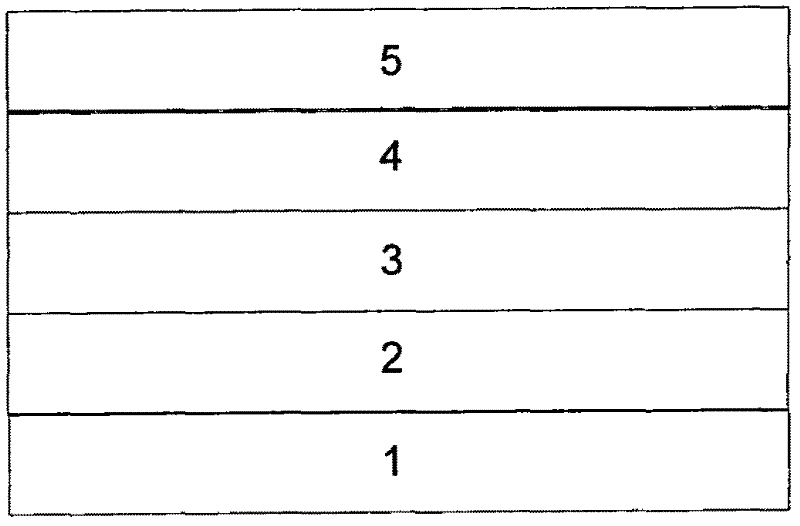

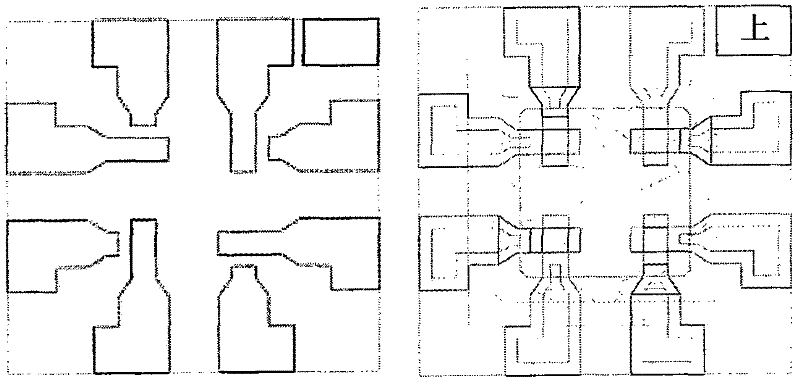

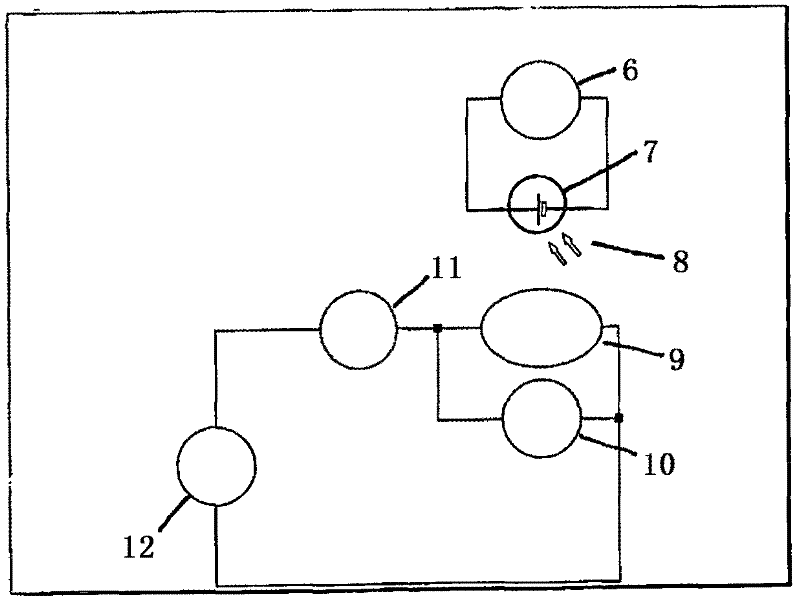

A device and electromechanical technology, applied in the field of preparation 4, can solve problems such as short service life, low conjugation, and difficulty in handling cleaning equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Example 1: Synthesis of 4,4'-bis(naphthalene-1-yl)-1,1'-dimethoxy-9,9'-spirobifluorene

[0096]

[0097] In 300ml toluene, 100ml di 25.5 g (120 mmol) of tripotassium phosphate in a mixture of alkanes and 400 ml of water, 913 mg (3 mmol) of tri-o-tolylphosphine, and then 112 mg (0.5 mmol) of palladium (II) acetate were added to well-stirred 26.7 g (50 mmol) of 4,4 '-Dibromo-1,1'-dimethoxy-9,9'-spirobifluorene and 22.4g (130mmol) of 1-naphthaleneboronic acid in suspension, and then the mixture was heated to reflux for 16h. After cooling, the precipitated solid was filtered off with suction, washed three times with 50 ml of toluene, three times with 50 ml of ethanol:water (1:1, volume:volume), and three times with 100 ml of ethanol, then removed from DMF (about 10 ml / g) was recrystallized three times. Yield: 20 g (31 mmol), 65.0%, purity: 99.9% (HPLC).

Embodiment 2

[0098] Example 2: Synthesis of 4,4'-bis(naphthalene-1-yl)-9,9'-spirobifluorene

[0099]

[0100] Mix well stirred 31.5g (50mmol) 4,4'-bis(naphthalene-1-yl)-1,1'-dimethoxy-9,9'-spirobifluorene, 18.1g (100mmol) 1-benzene Base-5-chlorotetrazole and 27.6g (200mmol) K 2 CO 3 The suspension was heated to reflux in 250ml acetone for 18h. After cooling, the precipitated solid was filtered off with suction and dried. The solid was dissolved in 200 ml of toluene, 6 g of 5% Pd / C was added, and the mixture was stirred at 40° C. under hydrogen atmosphere for 8 h. After removal of the solvent, the residue was washed three times with 50 ml ethanol:water (1:1, v:v), three times with 100 ml ethanol, and then recrystallized three times from DMF (about 10 ml / g). Yield: 18.7 g (33 mmol), 69.0%, purity: 99.9% (HPLC).

Embodiment 3

[0101] Example 3: Synthesis of 4,4'-bis(diphenylamino)-1,1'-dimethoxy-9,9'-spirobifluorene

[0102]

[0103] Add 190 μL (1 mmol) di-tert-butylphosphine chloride, then 112 mg (0.5 mmol) palladium(II) acetate to 19.7 g (37 mmol) 4,4′-dibromo-1,1′-dimethoxy-9 , 9'-spirobifluorene, 10.2g (60mmol) of diphenylamine and 7.7g (80mmol) of sodium tert-butoxide in 500ml of toluene suspension, and then the mixture was heated to reflux for 5h. After cooling to 60° C., 500 ml of water are added, the organic phase is separated off, filtered through silica gel, evaporated to near dryness in vacuo at 80° C., and then 300 ml of ethanol are added. After cooling, the solids were filtered off with suction. from two Alkanes (about 8ml / g) recrystallized five times. Yield: 18.8 g (26.5 mmol), 72%, purity 87% (HPLC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com