Compositions and methods for improved saccharification of biomass

A biomass, carbohydrate technology, applied in the field of compositions and methods for improved saccharification of biomass, can solve problems such as increasing fermentation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0198] Large-scale production of fermentation end products from biomass

[0199] In one aspect, microbial organisms such as C. phytofermentans or Clostridium sp. Q.D are used for large-scale production of fermentation end products (eg, ethanol) from biomass. In one embodiment, one first hydrolyzes a biomass material including high molecular weight carbohydrates to low molecular weight carbohydrates, and then uses microbial cells to ferment the low molecular weight carbohydrates to produce ethanol. In another embodiment, one ferments the biomass material itself without chemical and / or enzymatic pretreatment. In the first method, acids (such as Bronsted acids, such as sulfuric acid or hydrochloric acid), alkalis (such as sodium hydroxide), heat treatment, steam explosion, ammonia fiber expansion ("AFEX"), lime method, enzymes or their combined to complete the hydrolysis. Hydrogen and other products of fermentation can be captured and purified if desired, or disposed of by, for...

Embodiment 1

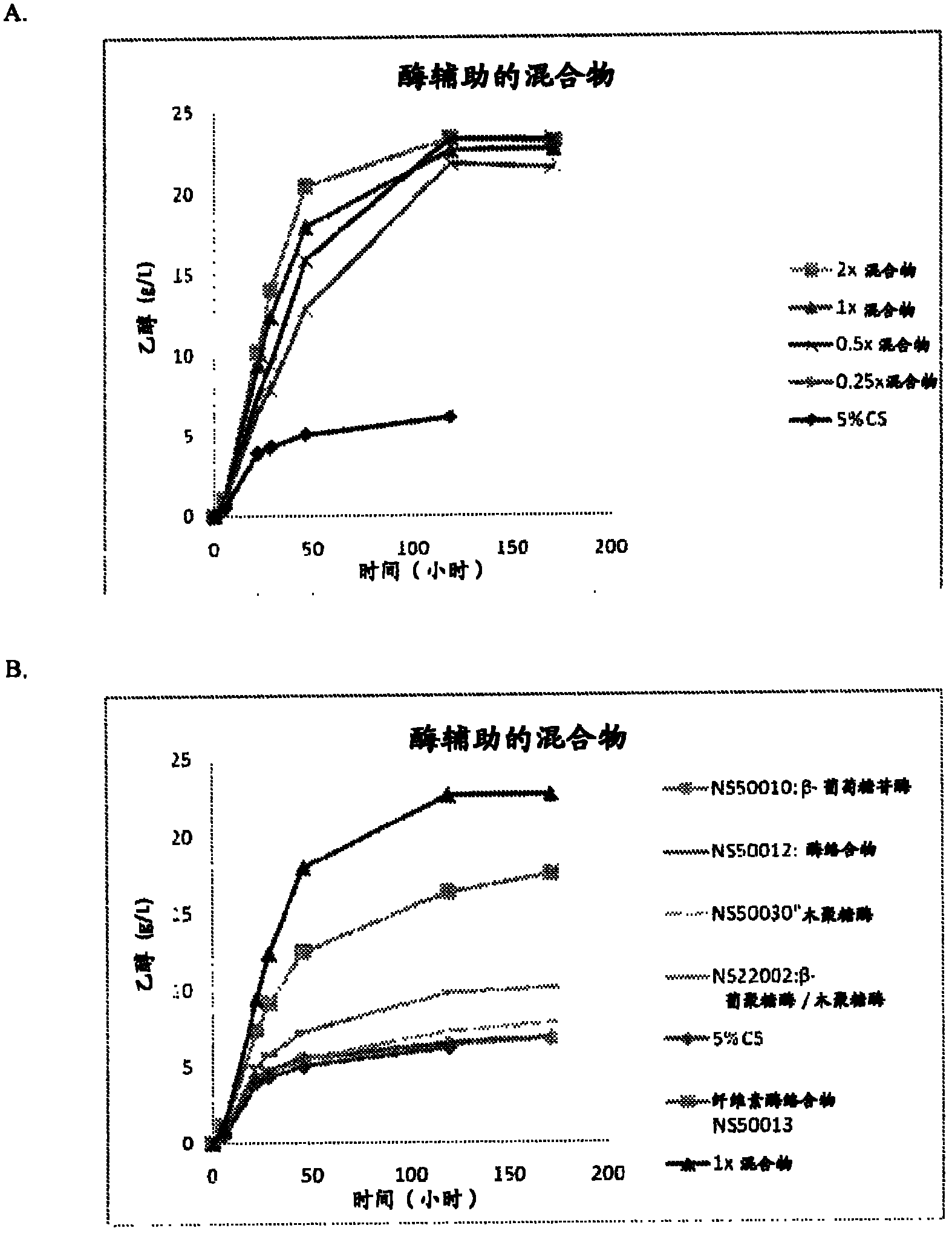

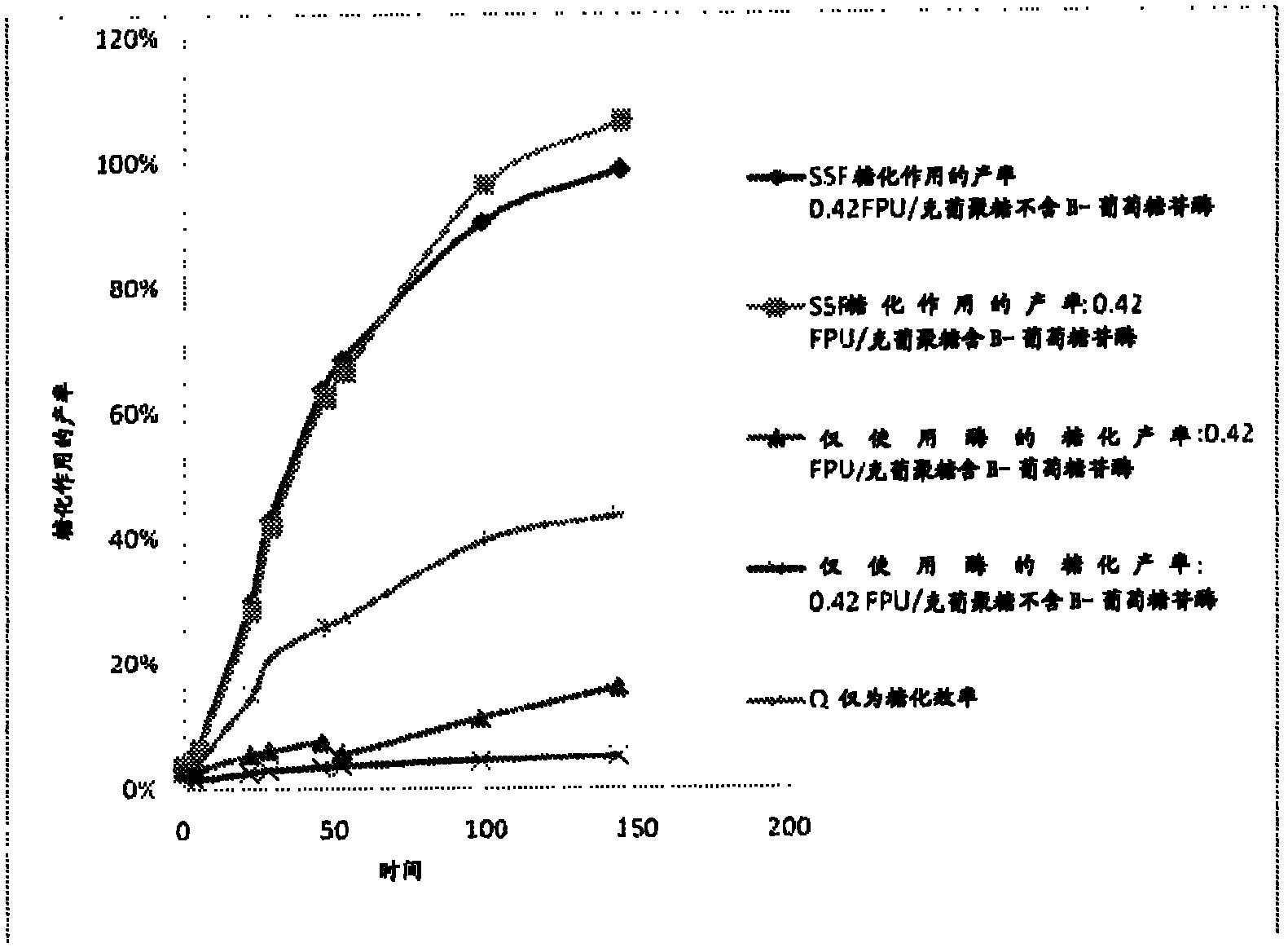

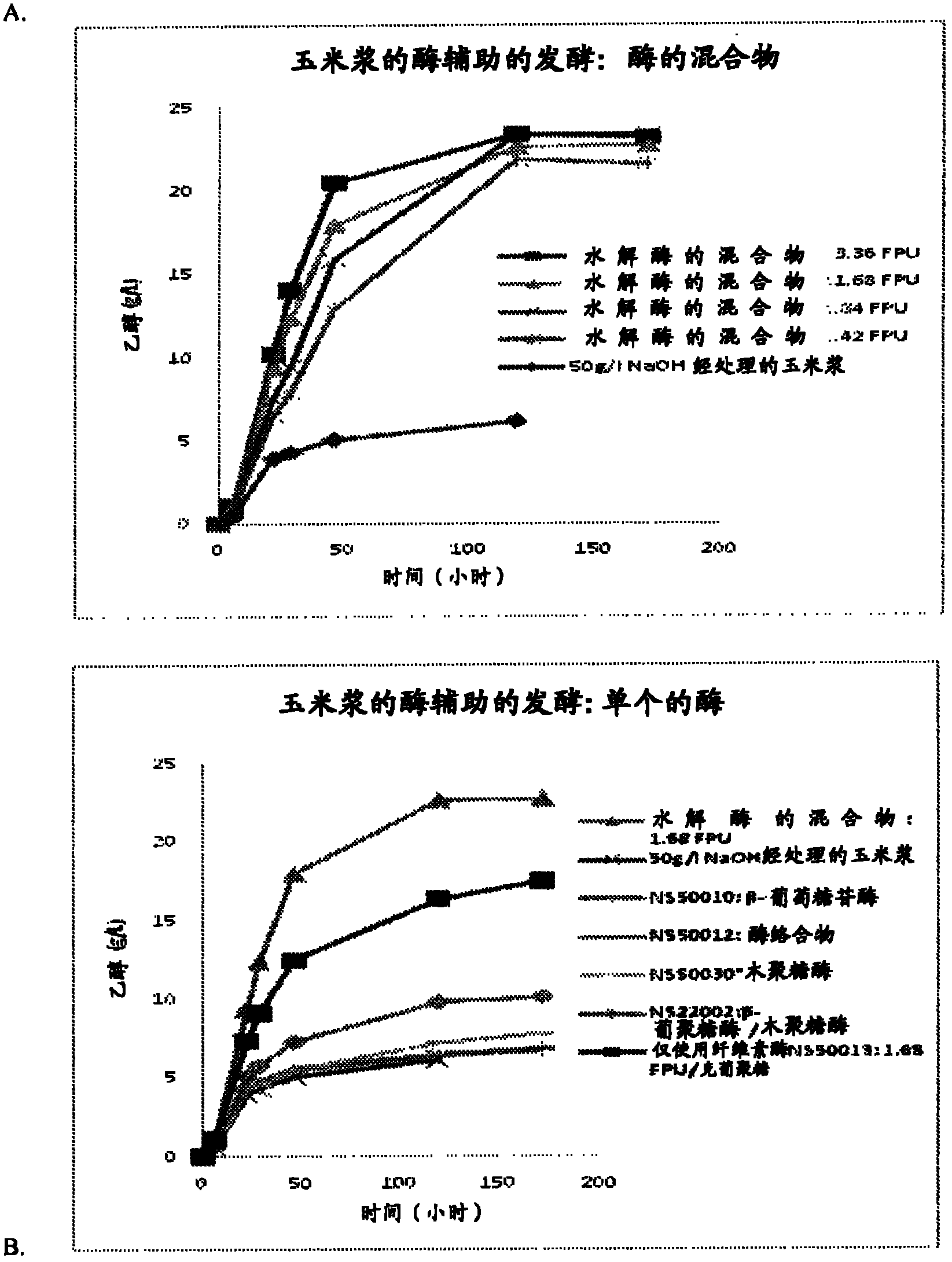

[0250] Example 1. Adding cellulase

[0251] To study the effect of supplementing exogenous enzymes, a mixture of hydrolytic enzymes and individual hydrolytic enzymes were added during the fermentation of corn stover biomass.

[0252] The following operating conditions and processing parameters were then implemented for C. phytofermentans for fermentation of NaOH-pretreated corn stover with enhanced enzymes in 250 ml shake flasks containing 100 ml of medium (Table 3).

[0253] table 3

[0254]

[0255]

[0256] Seed Propagation Medium (QM1) Formula:

[0257]

[0258]

[0259]

[0260] Seed propagation medium was prepared according to the method described above. Degas basal medium, salts, and substrates with nitrogen, then autoclave. After sterilization, combine 94ml of basal medium with 1ml of 100x salts and 5ml of 20x substrate to give the final concentration. All supplements were prepared under anaerobic and sterile conditions.

[0261] Fermentation me...

Embodiment 2

[0282] Example 2. Modification of microorganisms

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com