Thermosetting electrode paste fireable at a low temperature

A low-temperature firing and electrode paste technology, which is applied in electrode system manufacturing, circuits, photovoltaic power generation, etc., can solve problems such as poor adhesion of ceramic substrates and silicon substrates, slow reaction speed and curing time, and stability of paste viscosity rise. , to achieve the effect of excellent adhesion, better storage stability and excellent curing degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to 6 and comparative example 1 and 2

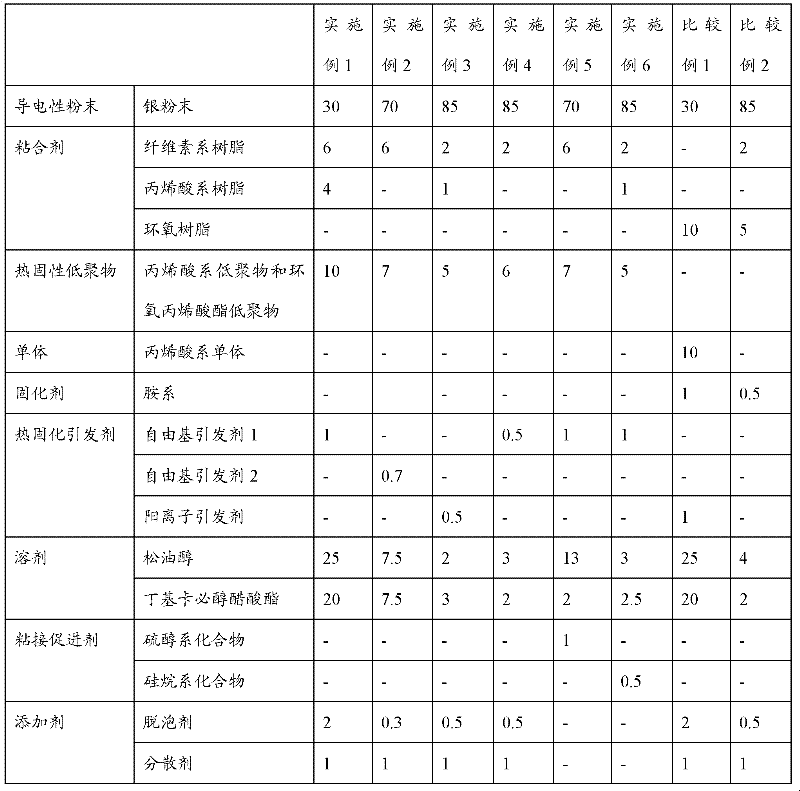

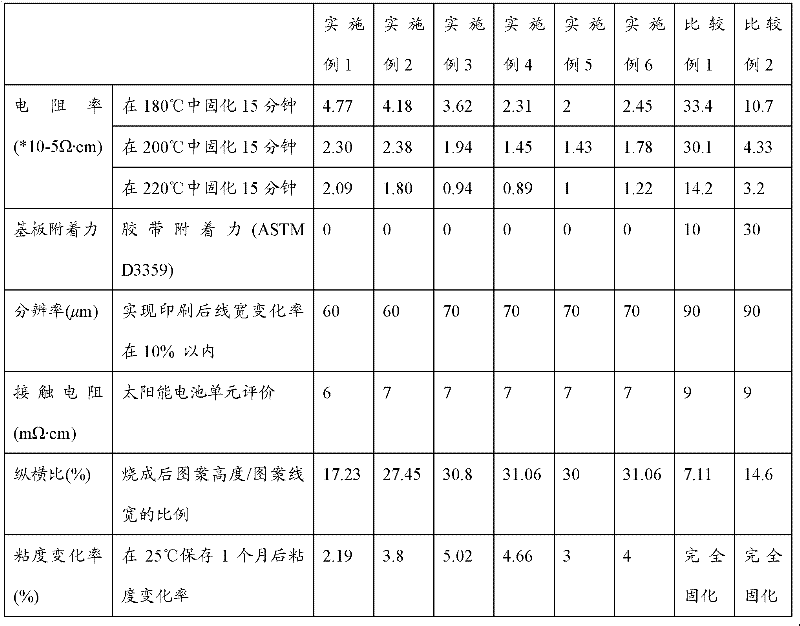

[0076] After mixing the components and contents described in the following Table 1 (% by weight), they were mixed and dispersed with a three-roll kneader to prepare an electrode paste.

[0077] Table 1

[0078]

[0079] The specific component names described in the above-mentioned Table 1 are as follows.

[0080] - Silver powder: flaky silver powder with an average particle size of 2.5 μm

[0081] - Cellulosic resin: Hydroxycellulose

[0082] -Acrylic resin: ELVACITE 2045

[0083] - Epoxy resin: bisphenol A resin

[0084] - Acrylic Oligomer and Epoxy Acrylate Oligomer: Mix EBECRYL-1200 with Miramer ME 2010 in a 4:1 weight ratio

[0085] -Acrylic monomer: TMPTA mixed with HDDA at a weight ratio of 7:3

[0086] - Amine curing agent: polyamide

[0087] - Radical initiator 1: Azobisisobutyronitrile

[0088] - Radical Initiator 2: Benzoyl Peroxide

[0089] - Cationic Initiator: Triphenylmethyl Chloride

[0090] - Mercaptan compound: mixture of butanethiol: pentanethiol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com