(In, Mn) As nano-wires and preparation method thereof

A nanowire, single crystal technology, applied in the field of As nanowires with high Mn content, can solve the problem of not getting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of (In, Mn) As nanowire of the present invention comprises the following steps:

[0022] First, complete the various growth preparation procedures of the MBE equipment: confirm that In, Mn, Ga, As sources are installed in the system; cut the GaAs (001) single crystal substrate in the clean room and adhere it to the sample stage with In; The substrate and sample stage are dehydrated and baked in the entry and exit chamber, and the substrate and sample stage are baked to remove organic impurities in the buffer chamber; the growth chamber is cooled with liquid nitrogen to increase the background vacuum to 5×10 -10 Torr below.

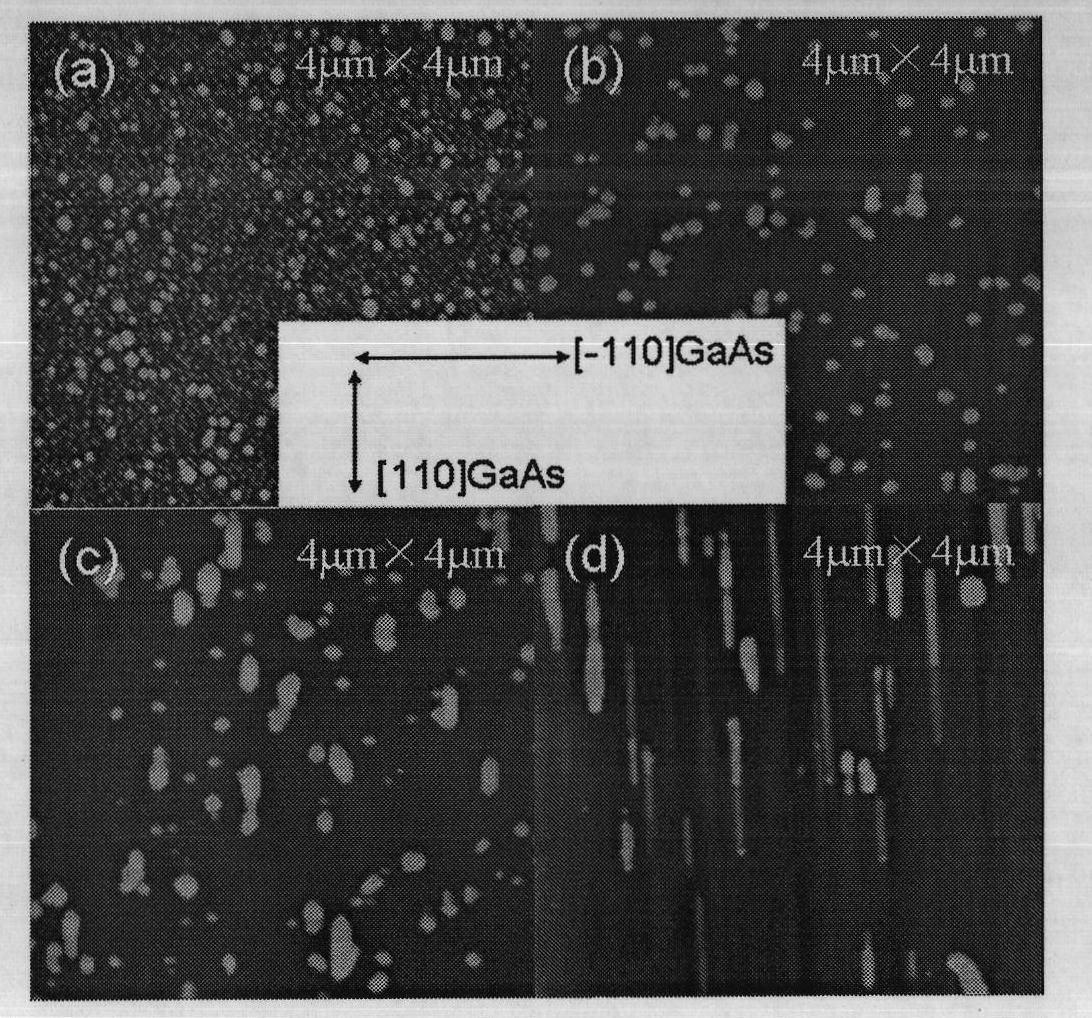

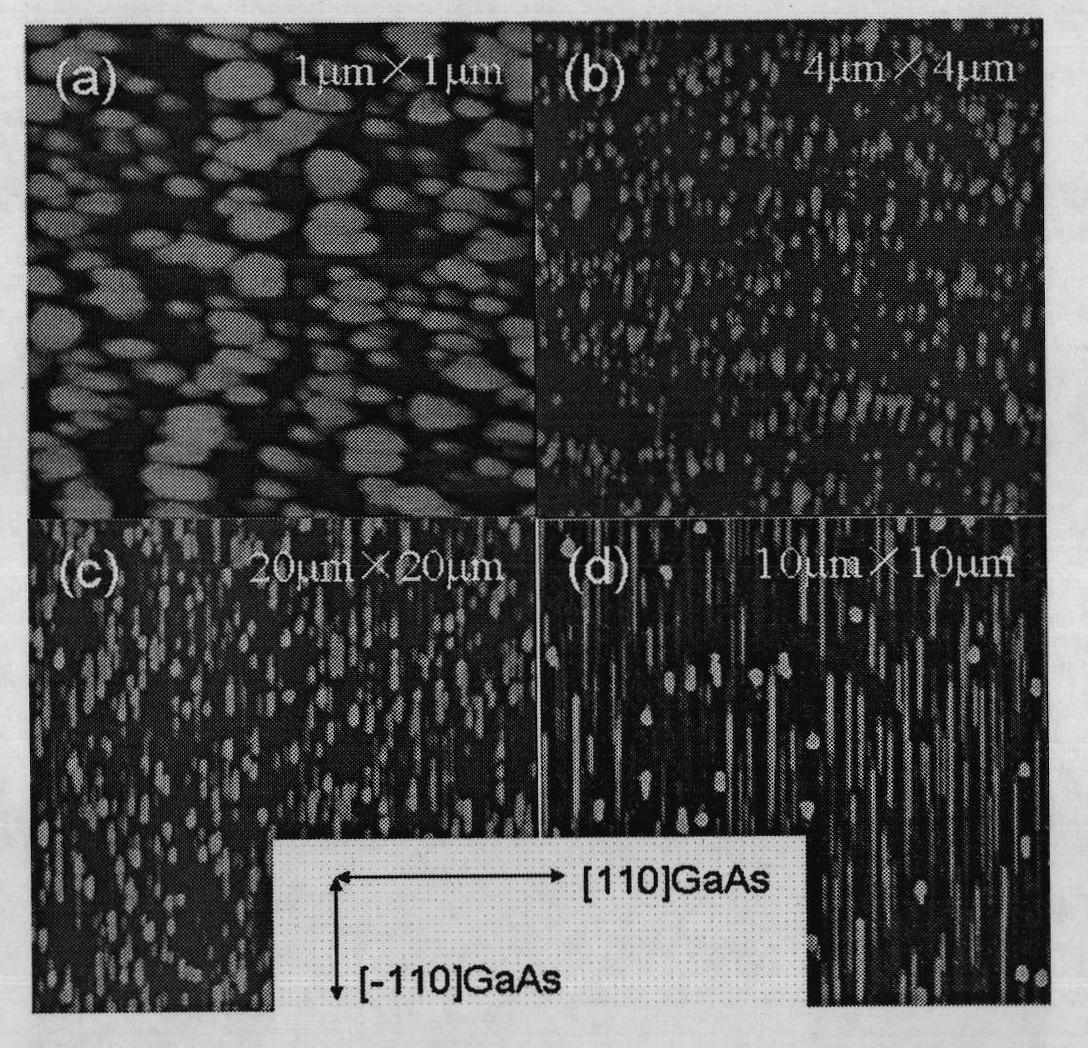

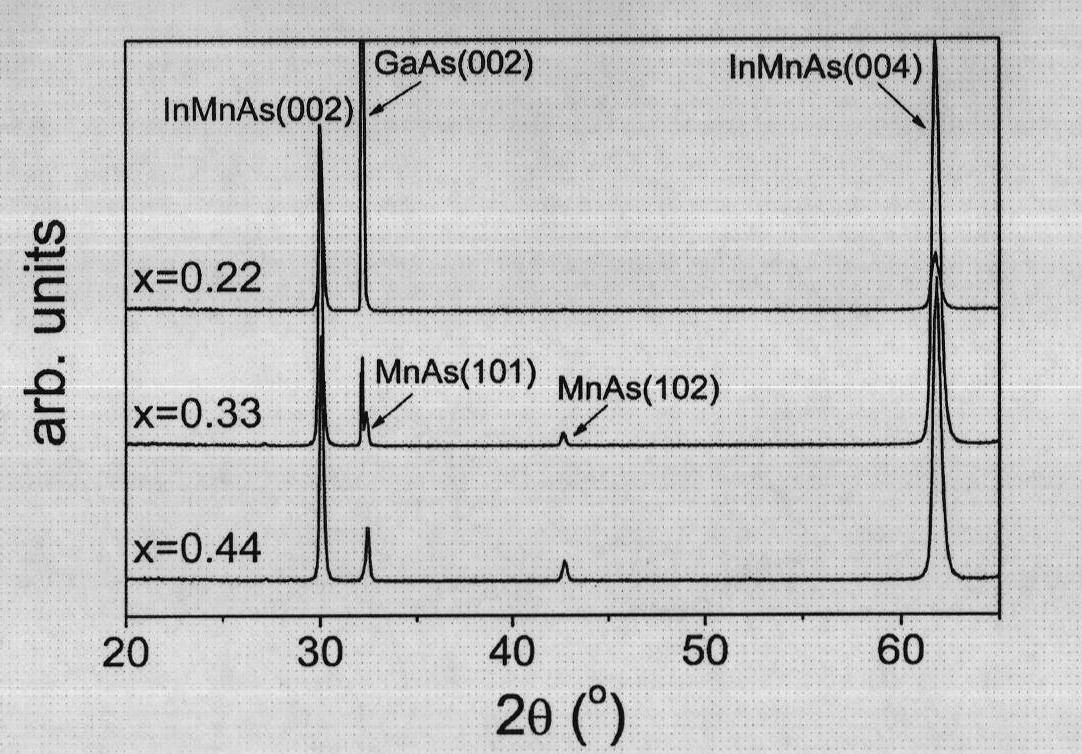

[0023] Then, in the growth chamber, increase the growth temperature to 20°C above the deoxidation temperature of GaAs(001) single crystal, and epitaxially grow a GaAs high-temperature buffer layer with a thickness of 200nm or more to improve the interface quality of heterogeneous growth; reduce the temperature to the set tempe...

Embodiment 1

[0027] 1. First confirm that the MBE system is equipped with at least high-purity Mn source, In source, Ga source, and As source (purity higher than 99.999%). Complete the various growth preparation procedures of the MBE equipment: cut the GaAs(001) single crystal substrate in the clean room according to the requirements and adhere it to the sample stage with molten In; put the substrate together with the sample stage into the inlet and outlet chamber, and Demoisture and bake the substrate and sample stage; transfer the substrate and sample stage to the buffer chamber, and bake the substrate and sample stage to remove organic impurities; cool the growth chamber with liquid nitrogen to increase the background vacuum degrees to 2×10 -10 Torr below.

[0028] 2. Transfer the substrate together with the sample stage to the growth chamber, increase the growth temperature to 20°C above the deoxidation temperature of the GaAs(001) single crystal substrate, and epitaxially grow a 500n...

Embodiment 2

[0032] 1. First confirm that the MBE system is equipped with at least high-purity Mn source, In source, Ga source, and As source (purity higher than 99.999%). Complete the various growth preparation procedures of the MBE equipment: cut the GaAs(001) single crystal substrate in the clean room according to the requirements and adhere it to the sample stage with molten In; put the substrate together with the sample stage into the inlet and outlet chamber, and Demoisture and bake the substrate and sample stage; transfer the substrate and sample stage to the buffer chamber, and bake the substrate and sample stage to remove organic impurities; cool the growth chamber with liquid nitrogen to increase the background vacuum degrees to 5×10 -10 Torr below.

[0033] 2. Transfer the substrate together with the sample stage to the growth chamber, increase the growth temperature to 20°C above the deoxidation temperature of the GaAs(001) single crystal substrate, and epitaxially grow a 200n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com