Void-containing heat-shrinkable polyester film and process for production thereof

A technology of heat shrinking and shrinking direction, used in chemical instruments and methods, flat products, other household appliances, etc., can solve problems such as difficult specific gravity, difficult polystyrene printing, poor perforation unsealing, and achieve good solvent adhesion. and mechanical strength, good shrinkage completion, good perforation unsealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8、 and comparative example 1~8

[0197]

Embodiment 1

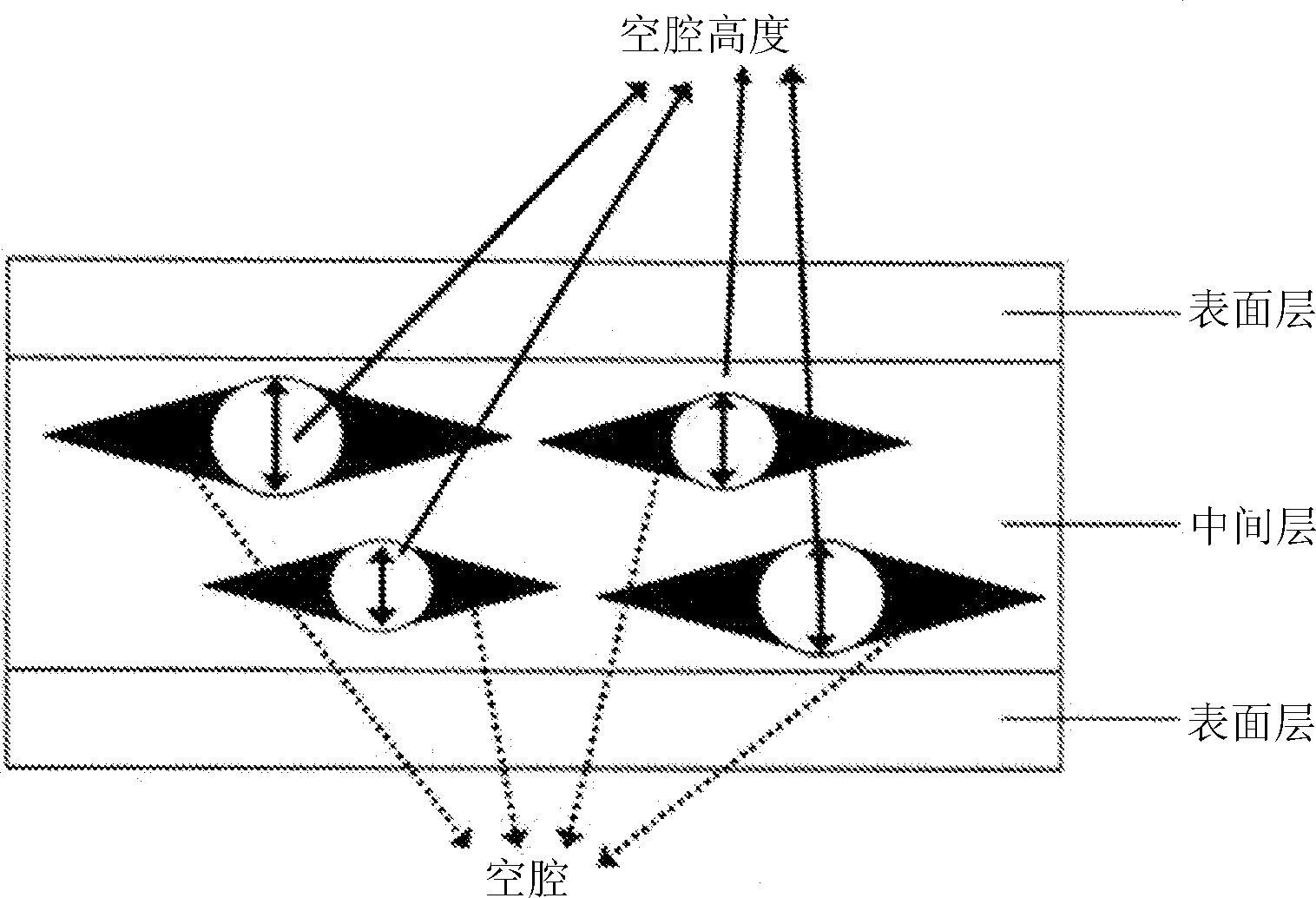

[0199] 6% by mass of polyester a and 94% by mass of polyester b were mixed as a layer A, and 45% by mass of polyester b was mixed with 15% by mass of polyester c, 10% by mass of polyester d, and 30% by mass of raw material e. The polyester of the B layer is melted at 280°C, and co-extruded from a T-shaped die so that the layer thickness ratio is A layer / B layer / A layer = 20 / 60 / 20, and quenched on a cooling roll to obtain the thickness An unstretched multilayer film of 160 μm. At this time, the shear speed of the T-shaped die is 150 seconds -1 , The draw ratio is 12.5.

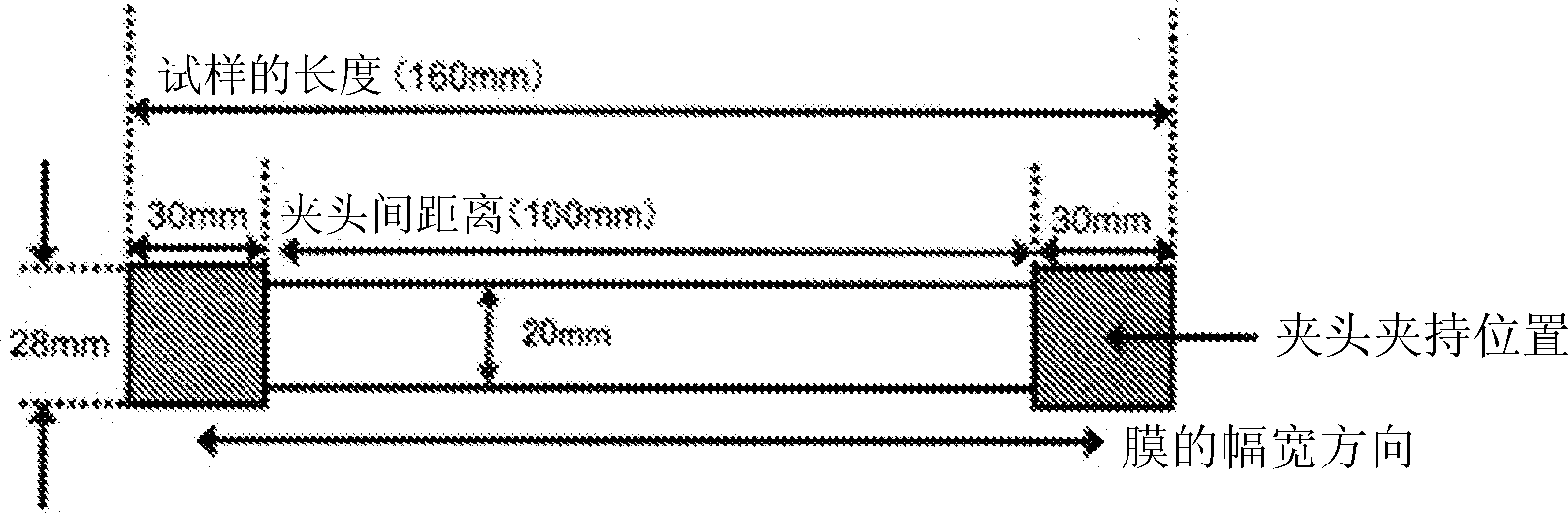

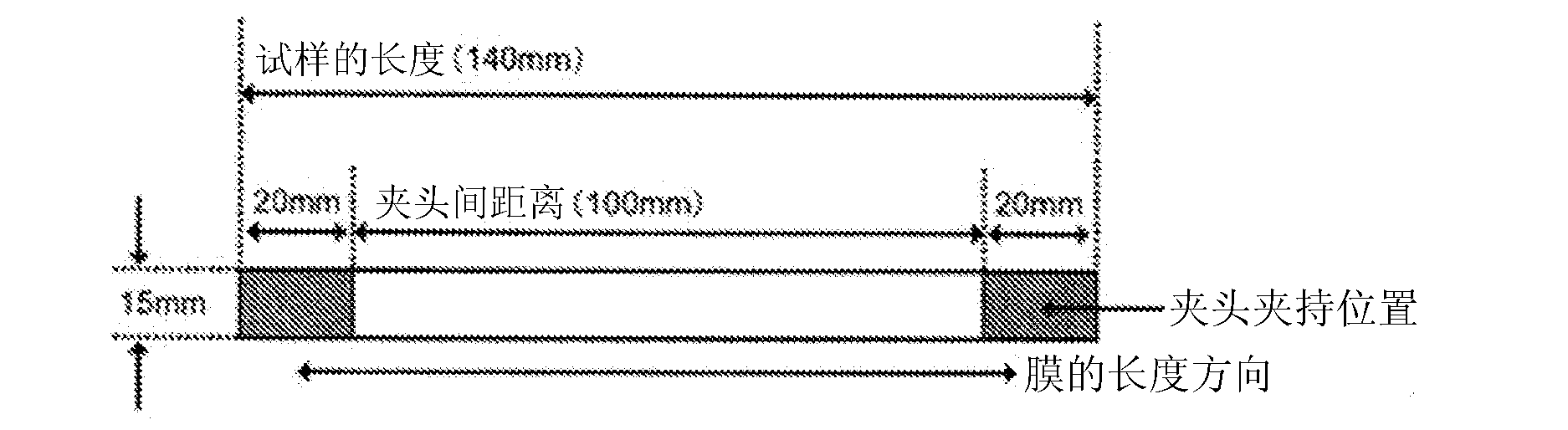

[0200] Then, the unstretched film obtained as described above is introduced into a longitudinal stretching machine in which a plurality of roll groups are continuously arranged, and stretched in the longitudinal direction by utilizing the difference in the rotational speed of the rolls. That is, after the unstretched film is preheated on the preheating roll until the film temperature reaches 85°C, it is rotat...

Embodiment 2

[0204] A biaxially stretched film was continuously produced by the same method as in Example 1, except that the stretch ratio in the longitudinal direction was set to 1.2 times and the thickness of the unstretched multilayer film was set to 125 μm. In addition, the shear rate of the T-die during melt extrusion is 150 seconds -1 , The draw ratio is 14.2. Then, the properties of the obtained film were evaluated by the same method as in Example 1. The evaluation results are shown in Table 4 and Table 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat shrinkage ratio | aaaaa | aaaaa |

| shrinkage stress | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com