Compound enzyme preparation and application of same in fermentation primary residue of soy sauce

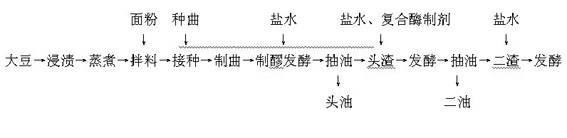

A composite enzyme preparation and a composite protease technology are applied to the composite enzyme preparation and its application in soy sauce fermentation slag to achieve the effects of reducing production costs and improving flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

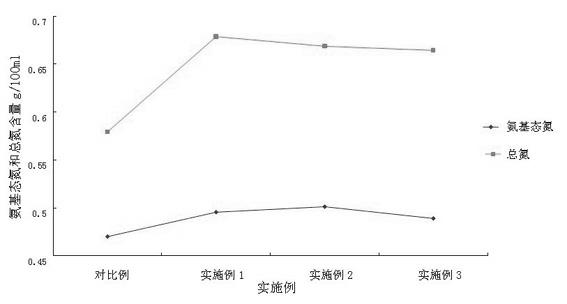

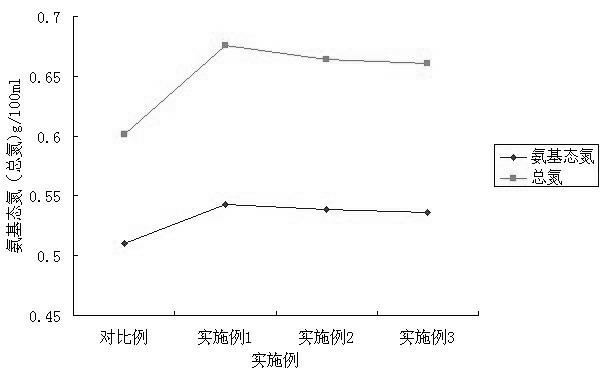

Examples

Embodiment 1

[0027] The weight percent of each component for preparing the compound enzyme preparation is: 5% amylase, 60% compound protease, 20% cellulase, 10% pectinase, and 5% beta-glucanase. The compound protease is composed of papain, neutral protease and trypsin with a mass ratio of 5:5:1.

[0028] The preparation method is as follows: each component is processed through a 60-mesh sieve, and then put into a V-shaped dry granule mixer in proportion for mixing and compounding, and then packaged to become a product.

Embodiment 2

[0030] The percentage by weight of each component for preparing the compound enzyme preparation is: amylase 7%, compound protease 58%, cellulase 17%, pectinase 15%, β-glucanase 3%. The compound protease is composed of papain, neutral protease and trypsin with a mass ratio of 5:5:1.

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0033] The weight percent of each component for preparing the compound enzyme preparation is: amylase 3%, compound protease 65%, cellulase 16%, pectinase 12%, β-glucanase 4%. The compound protease is composed of papain, neutral protease and trypsin with a mass ratio of 5:5:1.

[0034] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com