Method for producing metal hollow balls

A metal hollow sphere and computer-controlled technology, which is applied in the field of preparation of metal hollow spheres, can solve problems such as lack of patents, and achieve the effects of convenient realization, wide application range, and simple steps of the preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

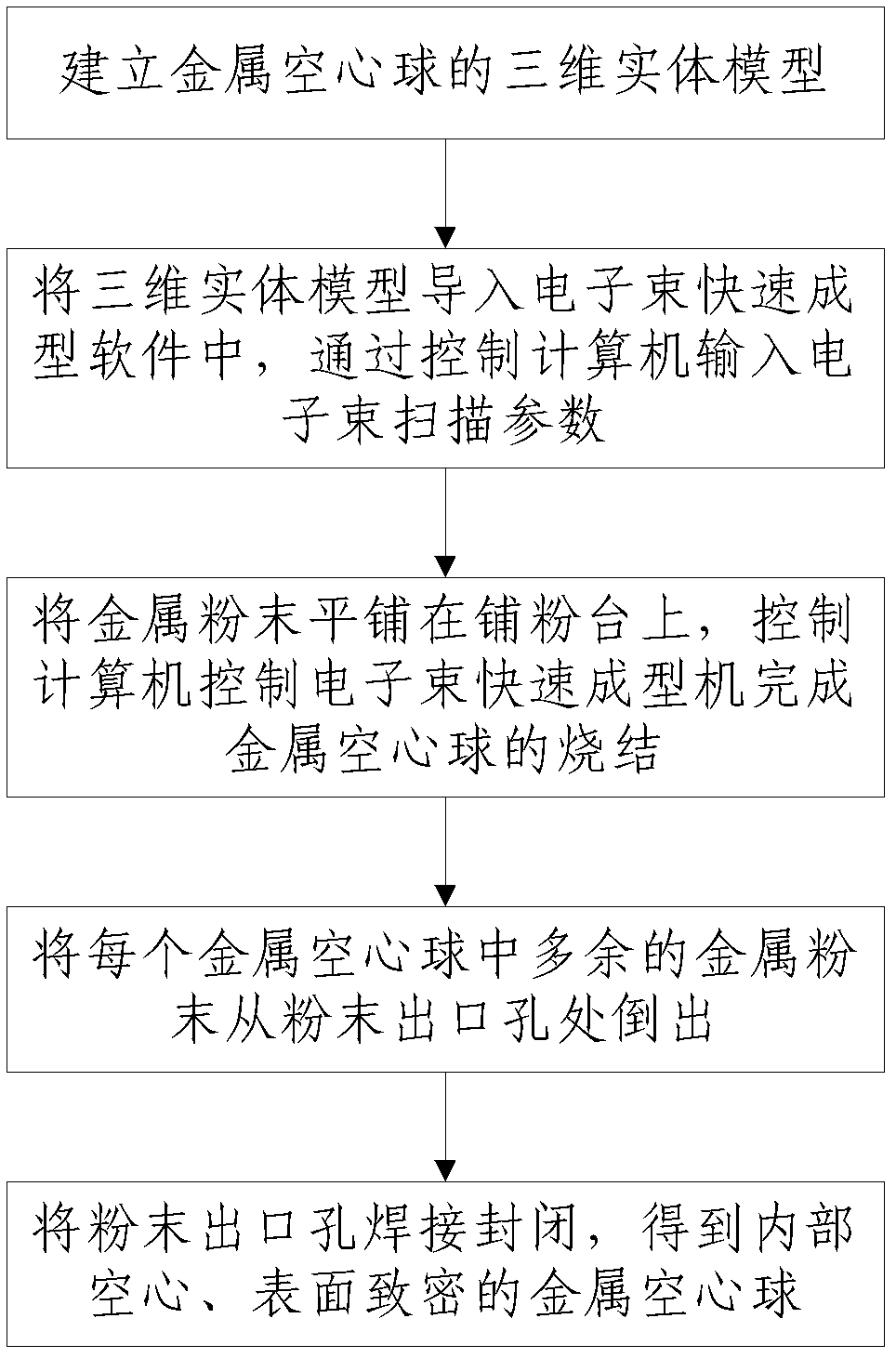

[0031] Such as figure 1 A method for preparing a hollow metal ball is shown. The equipment used in the method includes an electron beam rapid prototyping machine and a control computer connected to the electron beam rapid prototyping machine and used to control the working process of the electron beam rapid prototyping machine, so The control computer is equipped with drawing software and electron beam rapid prototyping software matched with the electron beam rapid prototyping machine; the method includes the following steps:

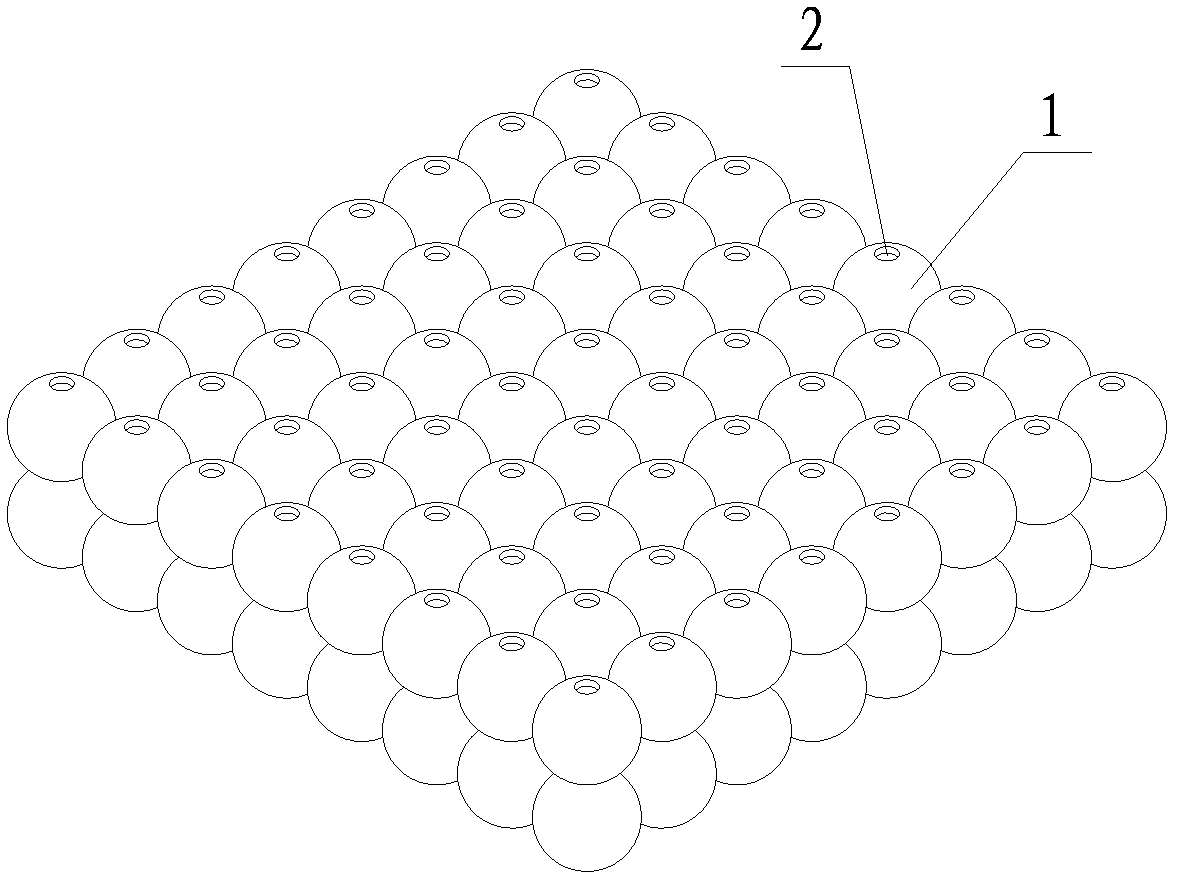

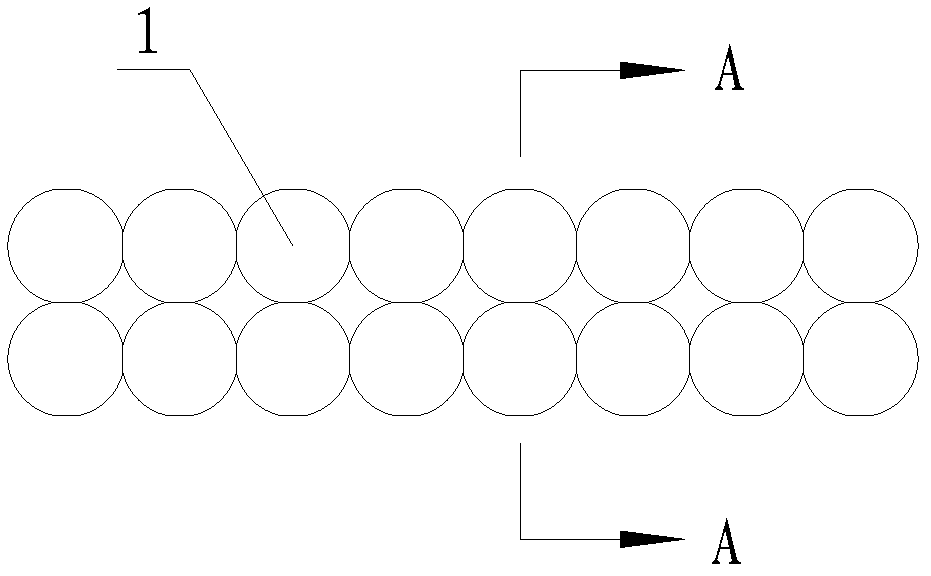

[0032] Step 1. Establish a three-dimensional solid model of the hollow metal ball 1: use the diameter and shell thickness of the hollow metal ball 1 to be prepared as a drawing software in the control computer to establish a three-dimensional solid model of the hollow metal ball 1. The model is composed of a plurality of metal hollow spheres 1 arranged in two layers. The top end of each metal hollow sphere 1 in the upper layer and the bottom end of each met...

Embodiment 1

[0040] In this embodiment, the metal hollow sphere to be prepared is a 316L stainless steel hollow sphere with a diameter of 5mm and a thickness of 0.1mm. The model of the electron beam rapid prototyping machine used is EBSM250; the preparation method is as follows:

[0041] Step 1. Establish a three-dimensional solid model of the 316L stainless steel hollow ball: use the control computer as a drawing software to establish a three-dimensional solid model of the 316L stainless steel hollow ball according to the diameter of 5mm and the thickness of the spherical shell of 0.1mm. The three-dimensional solid model consists of multiple arrangements. Two layers of 316L stainless steel hollow spheres are formed. The top end of each 316L stainless steel hollow sphere in the upper layer and the bottom end of each 316L stainless steel hollow sphere in the lower layer are provided with a powder outlet hole 2; wherein the powder outlet hole 2 is a circle Shaped hole and its diameter is 1mm; se...

Embodiment 2

[0048] In this embodiment, the metal hollow sphere to be prepared is a NiCrAlFe high-temperature alloy hollow sphere with a diameter of 6mm and a thickness of 0.2mm. The model of the electron beam rapid prototyping machine used is EBSM250; the preparation method is as follows:

[0049] Step 1. Establish a three-dimensional solid model of the hollow sphere of NiCrAlFe superalloy: According to the diameter of 6mm and the thickness of the spherical shell of 0.2mm, the three-dimensional solid model of the hollow sphere of NiCrAlFe superalloy is established as a drawing software in the control computer. Two layers of NiCrAlFe high-temperature alloy hollow spheres are arranged. The top end of each NiCrAlFe high-temperature alloy hollow sphere in the upper layer and the bottom end of each NiCrAlFe high-temperature alloy hollow sphere in the lower layer are provided with a powder outlet hole 2; Outlet hole 2 is a circular hole and its diameter is 1.5mm; see details figure 2 , image 3 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com