Energy-saving device and method for polycrystalline silicon reduction furnace with polycrystalline silicon insert heat insulation layer

A technology of polysilicon and thermal insulation layer, applied in the direction of silicon, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of poor mirror effect, reduced radiation heat transfer, thin furnace body thickness, etc., to facilitate disassembly and replacement , the effect of reducing radiant heat and reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

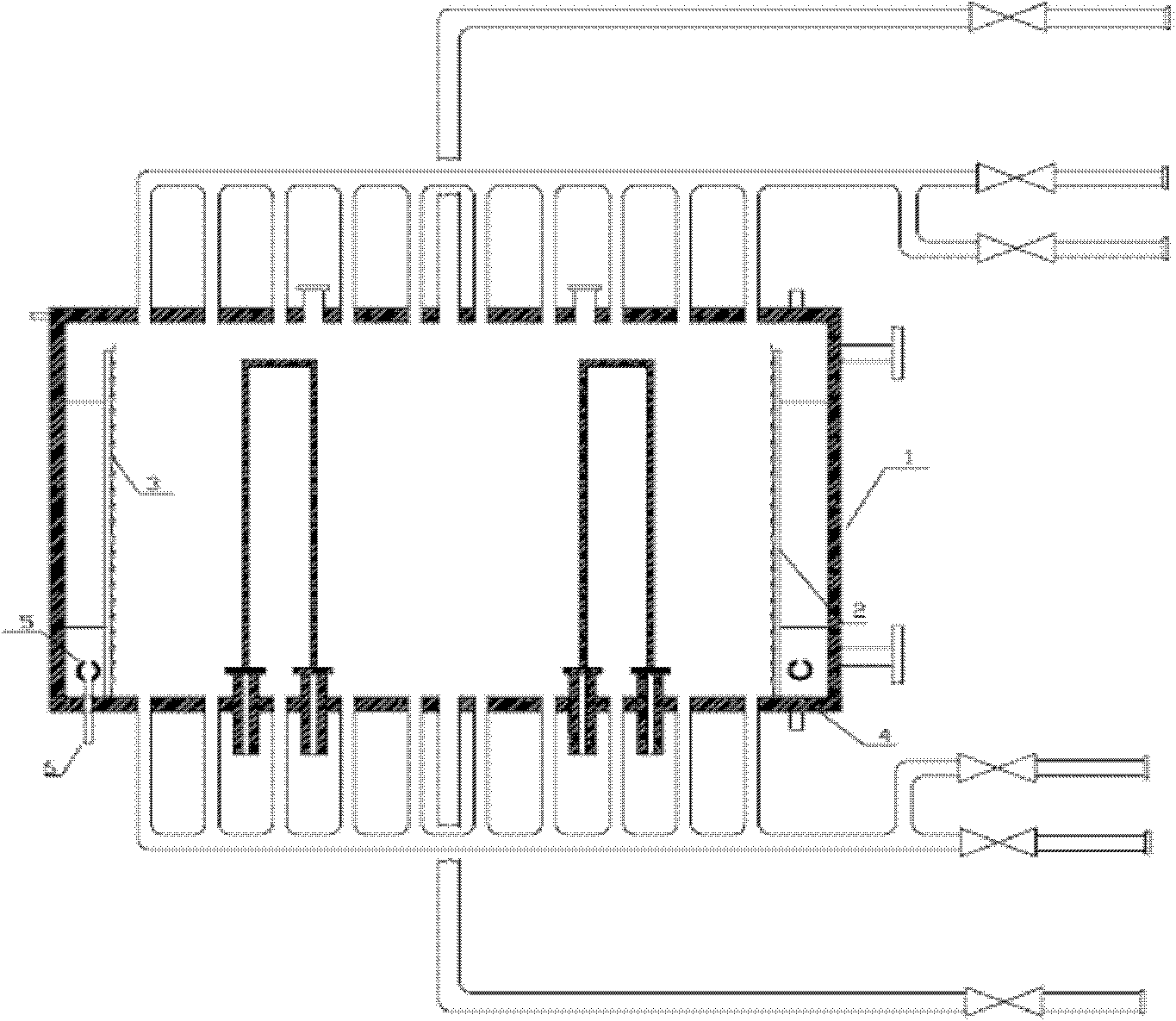

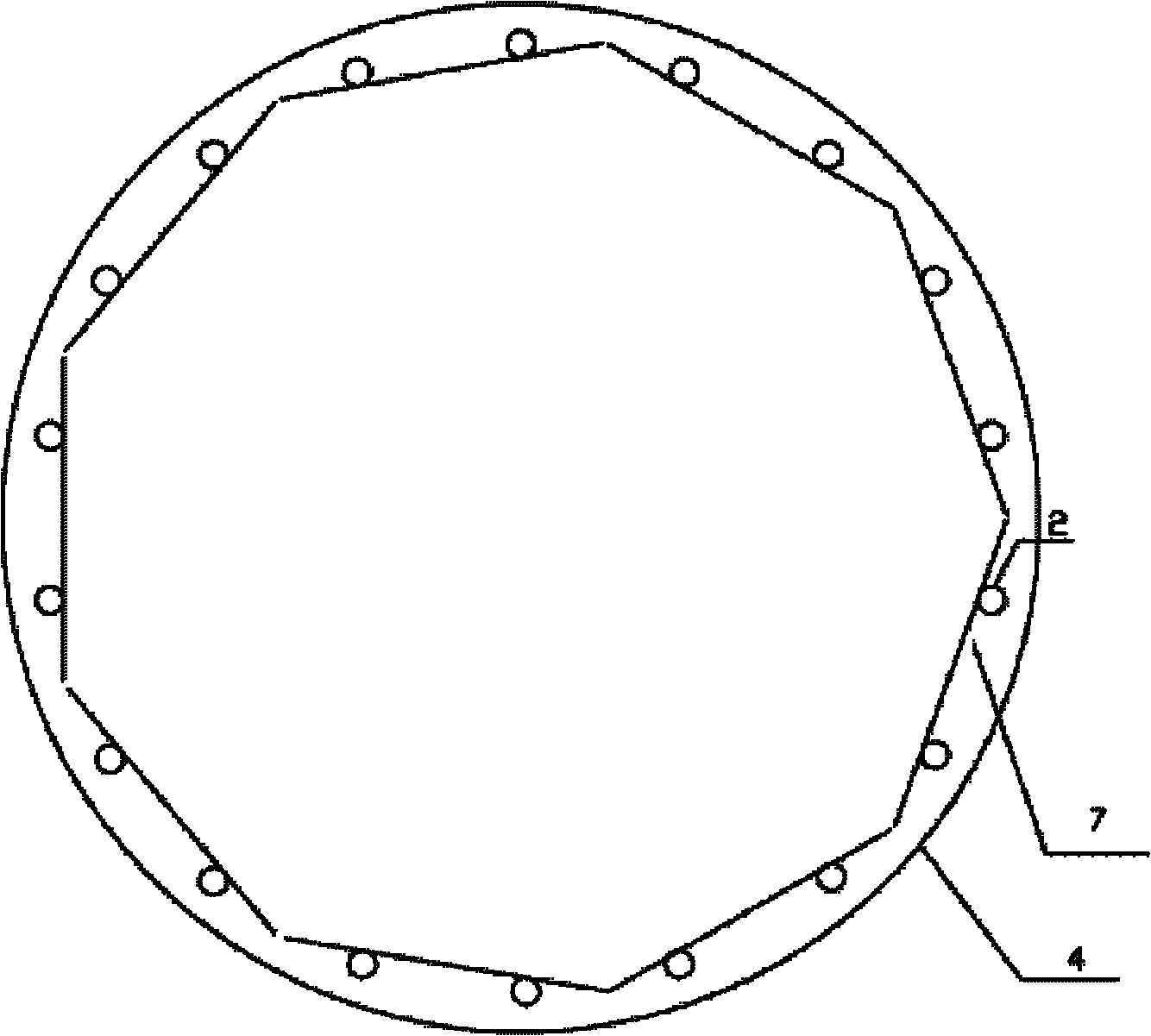

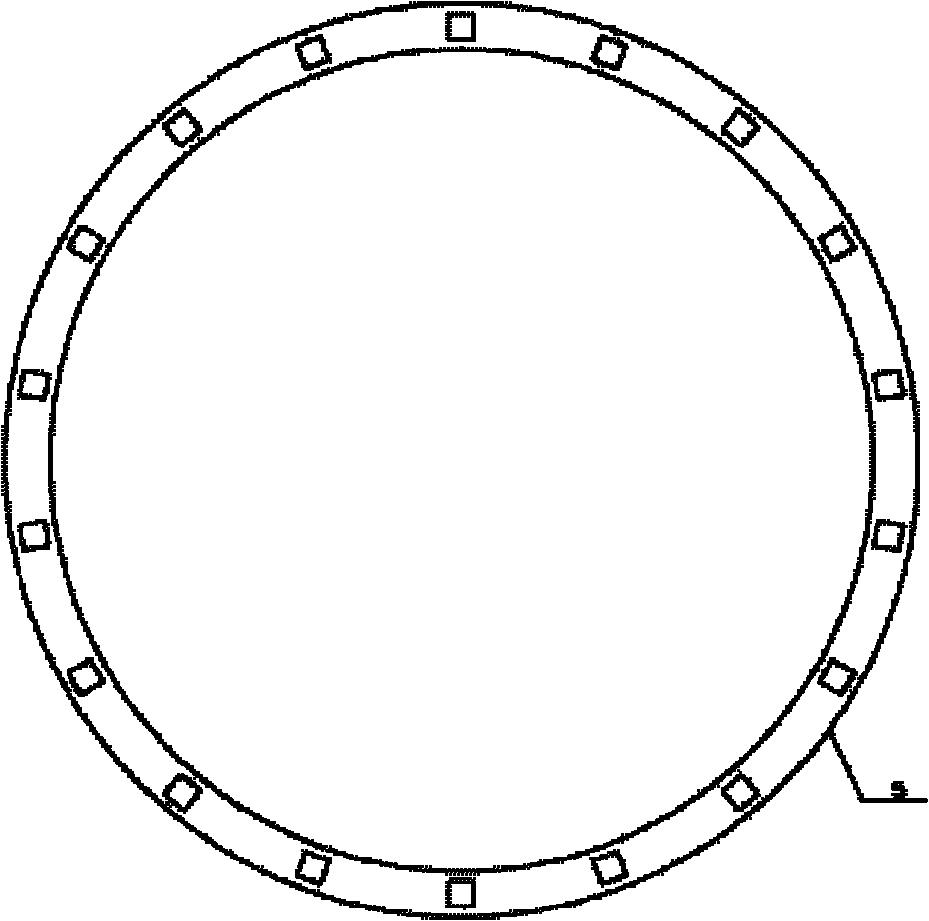

[0024] Implementation mode 1: if figure 1 , 2 As shown, the polysilicon reduction furnace includes: 1- double-layer furnace body with jacketed cooling water device, 2- stainless steel tube, 3- stainless steel plate with grooves, 4- reduction furnace chassis, 5- ring inlet pipe, 6 -Chassis air intake, 7-polysilicon inserts, 8-bolts. Among them, the double-layer furnace body (1) containing the jacket cooling water device is fixed on the reduction furnace chassis (4), and the stainless steel pipe (2) is connected with the furnace body (1) through bolts (8), as image 3 , 4 As shown, the column frame is made of stainless steel. The stainless steel tube is a square tube with a side length of 30mm and a width of the stainless steel plate of 40mm. The stainless steel tube (2) and the stainless steel plate (3) with grooves are connected by welding. The interval of the grooves on the stainless steel plate is 100mm and the depth is 50mm, the width of the groove is 0.25mm, the angle ...

Embodiment approach 2

[0028] Implementation mode 2: if figure 1 , 2 As shown, the polysilicon reduction furnace includes: 1- double-layer furnace body with jacketed cooling water device, 2- stainless steel tube, 3- stainless steel plate with grooves, 4- reduction furnace chassis, 5- ring inlet pipe, 6 -Chassis air intake, 7-polysilicon inserts, 8-bolts. Wherein, the double-layer furnace body (1) containing the jacket cooling water device is fixed on the reduction furnace chassis (4), the stainless steel pipe (2) is connected with the furnace body (1) by bolts (8), and the stainless steel pipe (2) and A thermal insulation layer composed of polysilicon inserts (7), such as image 3 , 4 As shown, the frame is made of stainless steel. The stainless steel tube is a square tube with a side length of 30mm and a width of the stainless steel plate of 40mm. The stainless steel tube (2) and the stainless steel plate (3) with grooves are connected by welding. The interval of the grooves on the stainless st...

Embodiment approach 3

[0033] Implementation mode 3: if figure 1 , 2 As shown, the polysilicon reduction furnace includes: 1- double-layer furnace body with jacketed cooling water device, 2- stainless steel tube, 3- stainless steel plate with grooves, 4- reduction furnace chassis, 5- ring inlet pipe, 6 -Chassis air intake, 7-polysilicon inserts, 8-bolts. Among them, the double-layer furnace body (1) containing the jacket cooling water device is fixed on the reduction furnace chassis (4), the column frame (2) and the furnace body (1) are connected by bolts (8), and the stainless steel pipe (2) and the heat insulation layer composed of polysilicon inserts (7), such as image 3 , 4 As shown, the frame is made of stainless steel. The stainless steel tube is a square tube with a side length of 40mm and a width of the stainless steel plate of 60mm. The stainless steel tube (2) and the stainless steel plate (3) with grooves are connected by welding. The interval of the grooves on the stainless steel pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com