Nuclear power concrete additive and preparation method thereof

A technology of concrete admixture and admixture, applied in the field of nuclear power concrete, to achieve the effect of reducing drying shrinkage, lowering peak temperature, and increasing the amount of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

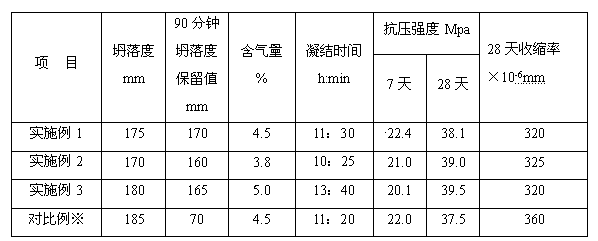

Examples

Embodiment 1

[0029] Ester polycarboxylate superplasticizer 40% Ether polycarboxylate slump retention agent 20% sodium gluconate 4% bio glue 0.1% Triethanolamine 3% Polyether air-entraining agent 0.5% benzoic acid 0.1% Polyether defoamer 0.5% water make it 100%

[0030] The product can be obtained by uniformly mixing the raw materials in the above mass percentages.

Embodiment 2

[0032] Ester polycarboxylate superplasticizer 50% Ether polycarboxylate slump retention agent 10% citric acid 3% Diethanolamine 10% soap locust air-entraining agent 0.2% fungicide 0.3% Polyether defoamer 0.5% water make it 100%

[0033] The product can be obtained by uniformly mixing the raw materials in the above mass percentages.

Embodiment 3

[0035] Ester polycarboxylate superplasticizer 55% Ether polycarboxylate slump retention agent 10% sucrose 4% Hydroxypropylmethylcellulose 0.5% Diethanolamine 10% soap locust air-entraining agent 0.1% Polyether defoamer 0.5% water make it 100%

[0036] The product can be obtained by uniformly mixing the raw materials in the above mass percentages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com