Modified polycarboxylic high performance water reducer and its production method and application method

A polycarboxylic acid, high-performance technology, applied in the field of water reducing agent, can solve the problems of environmental and human harm, complicated production process, harsh reaction conditions, etc., and achieve the effect of low production cost, easy to obtain and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

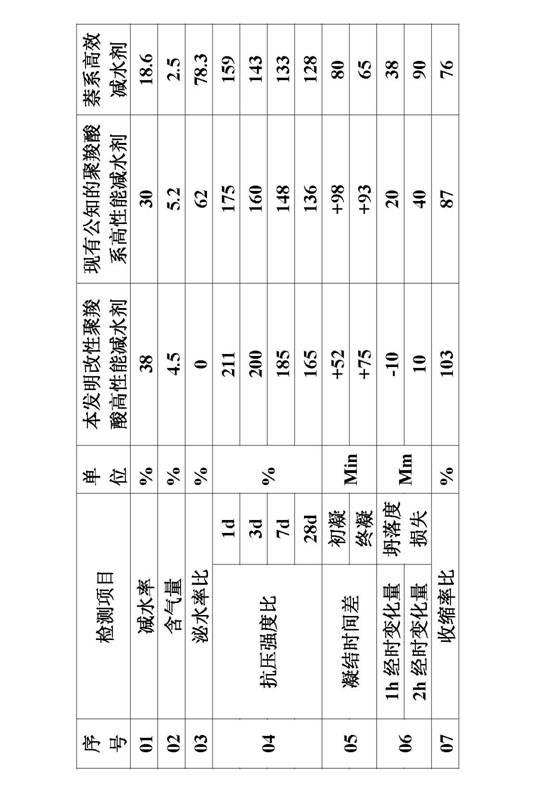

Image

Examples

Embodiment 1

[0025] Example 1, the modified polycarboxylic acid high-performance water reducer is produced according to the following raw material weight parts: 1 part to 3 parts of methallyl alcohol polyoxyethylene ether, 1 part of isopentenol polyoxyethylene ether , 0.4 to 0.6 parts of acrylic acid, 0 to 0.5 parts of methacrylic acid, 0 to 0.1 parts of maleic anhydride, 0.002 parts of hydrogen peroxide, 0.001 to 0.002 parts of ammonium persulfate, 5 to 6 parts of water, among which, pH control At 6.5 to 7.5, the molecular weight of methallyl alcohol polyoxyethylene ether is 150 to 6000, and the molecular weight of prenyl alcohol polyoxyethylene ether is 200 to 6000.

Embodiment 2

[0026] Example 2, the modified polycarboxylic acid high-performance water reducer is produced according to the following raw material weight parts: 1 part of methallyl alcohol polyoxyethylene ether, 1 part of isopentenol polyoxyethylene ether, 0.4 part of acrylic acid part, 0.002 part of hydrogen peroxide, 0.001 part of ammonium persulfate, and 5 parts of water, wherein the pH is controlled at 6.5, the molecular weight of methallyl alcohol polyoxyethylene ether is 150 to 6000, and the molecular weight of isopentenol polyoxyethylene ether is 200 to 6000.

Embodiment 3

[0027] Example 3, the modified polycarboxylic acid high-performance water reducer is produced according to the weight of the following raw materials: 3 parts of methallyl alcohol polyoxyethylene ether, 1 part of isopentenol polyoxyethylene ether, 0.4 parts of acrylic acid 0.5 parts of methacrylic acid, 0.1 parts of maleic anhydride, 0.002 parts of hydrogen peroxide, 0.002 parts of ammonium persulfate, and 6 parts of water, wherein the pH is controlled at 7.5, and the molecular weight of methallyl alcohol polyoxyethylene ether is 150 to 6000 , The molecular weight of isopentenol polyoxyethylene ether is 200 to 6000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com