Method for extracting daptomycin from fermentation broth

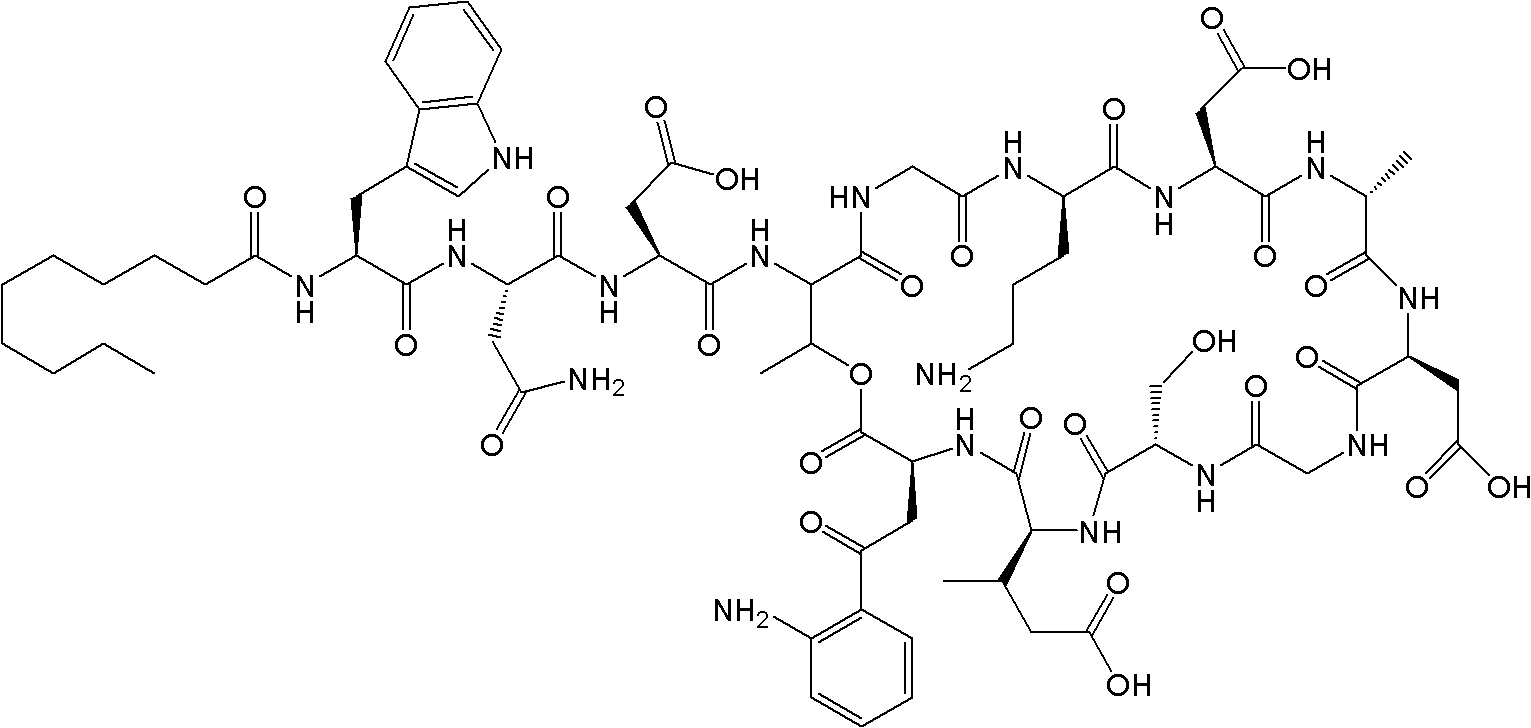

A technology for daptomycin and fermentation broth, applied in the field of fermentation broth, can solve the problems of acid hydrolysis of daptomycin, large pollution, increase the cost of separation and purification, etc., and achieves reduction of acid hydrolysis, low cost, significant economic and social value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

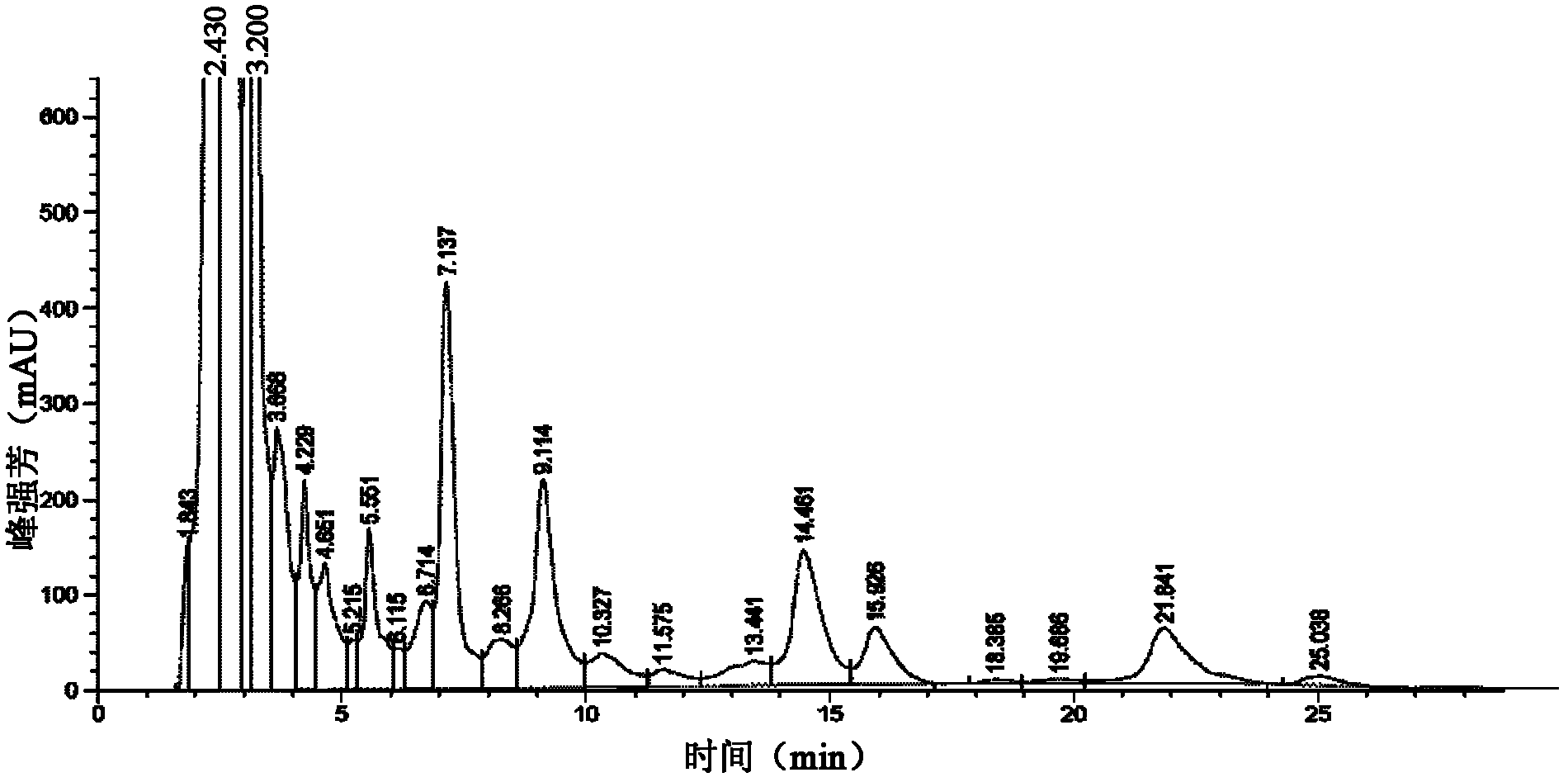

[0025] 1) The daptomycin fermentation broth was centrifuged at 4800rpm for 15min to remove the mycelia to obtain the fermentation supernatant (see figure 1 ). Adjust the pH of the supernatant to 5.0, add 1 / 4 volume of n-butanol, extract 3 times, 95% of the daptomycin in the supernatant enters the organic phase, 3 volumes of pH 7.0 sodium acetate-acetate buffer Daptomycin was back extracted into the aqueous phase.

[0026] 2) The pH of the stripping solution was adjusted to 5.0, and the sample was loaded on a chromatographic column filled with HP20 macroporous adsorption resin. The flow rate was 1.0mL / min. -Sodium acetate-acetate buffer gradient elution, collect macroporous adsorption eluate.

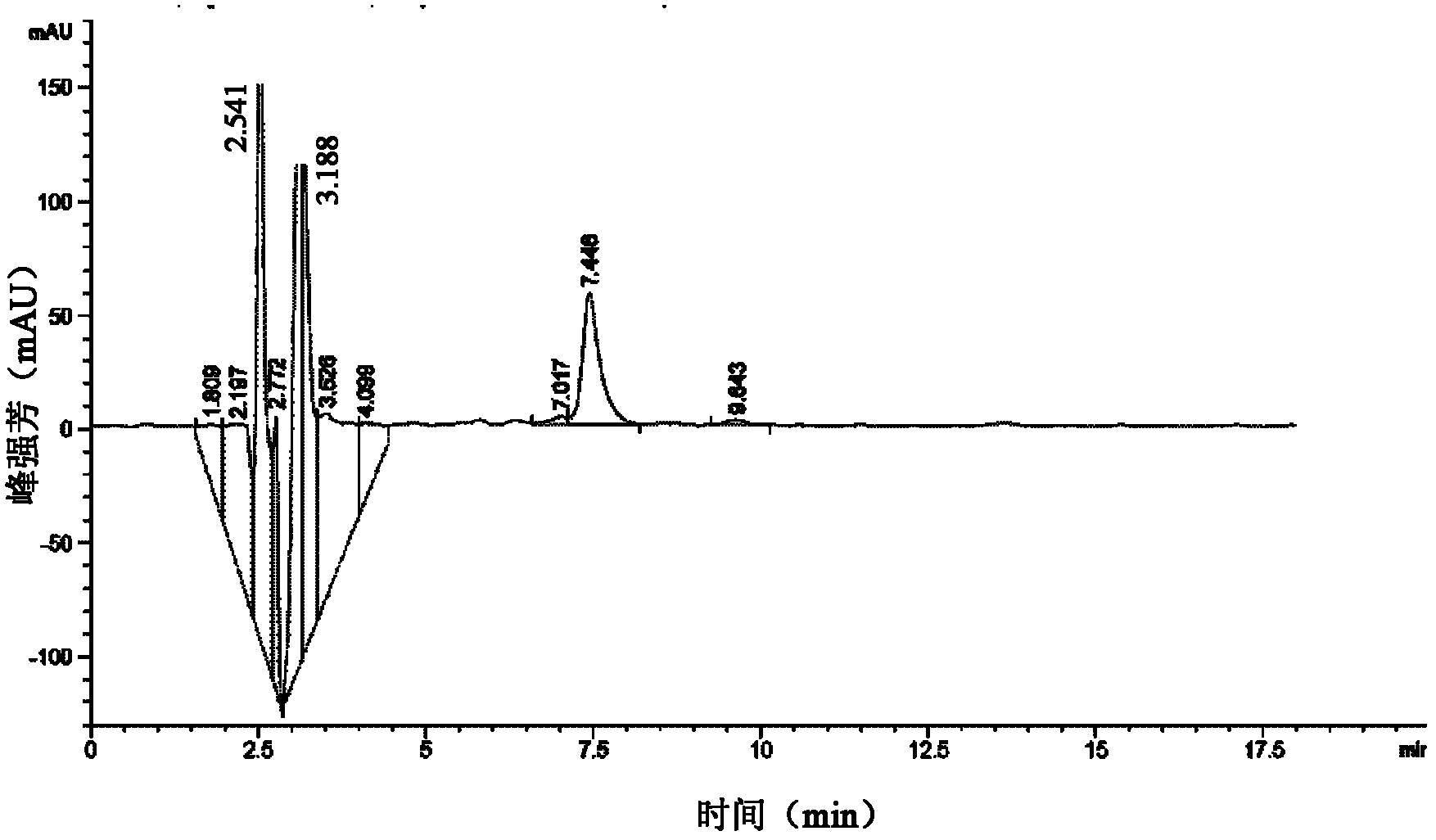

[0027] 3) The macroporous adsorption eluent was loaded onto a DEAE Sepharose FF ion-exchange chromatography column that was pre-balanced with sodium acetate-acetic acid buffer at a flow rate of 2mL / min. The buffer was fully washed, and 50mM pH 7.0 sodium acetate-acetic acid buffer was...

Embodiment 2

[0029] 1) The daptomycin fermentation broth was centrifuged at 4800 rpm for 15 minutes to remove the mycelia to obtain the fermentation supernatant. Adjust the pH of the supernatant to 4.5, add 1 / 4 volume of n-pentanol, extract 4 times, and back-extract the daptomycin into the water phase with 3 volumes of pH 7.5 sodium acetate-acetate buffer.

[0030] 2) The pH of the stripping solution was adjusted to 4.5, and the sample was loaded on a chromatographic column filled with HZ816 macroporous adsorption resin, the aspect ratio was 20, and the flow rate was 1.0mL / min. %, 40% isopropanol-sodium acetate-acetate buffer gradient elution, and the macroporous adsorption eluate was collected.

[0031] 3) The macroporous adsorption eluent is loaded on the DEAE52 ion exchange chromatography column which has been pre-balanced with sodium acetate-acetate buffer at a flow rate of 2mL / min. Wash thoroughly, use 50mM pH7.0 sodium acetate-acetic acid buffer as the base solution, add NaCl for li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com