Water-dispersed fluorine-containing hydroxyl acrylic-epoxy ester heterozygous body resin and coating thereof

A technology of fluorine-containing hydroxyl acrylic acid and epoxy resin, which is applied in the direction of coating, etc., can solve the problems of insufficient water resistance and corrosion resistance of the paint film, the need for high temperature curing, and unfavorable wide application, etc., to improve adhesion and corrosion resistance, The reactivity rate is similar and the effect of increasing the degree of copolymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

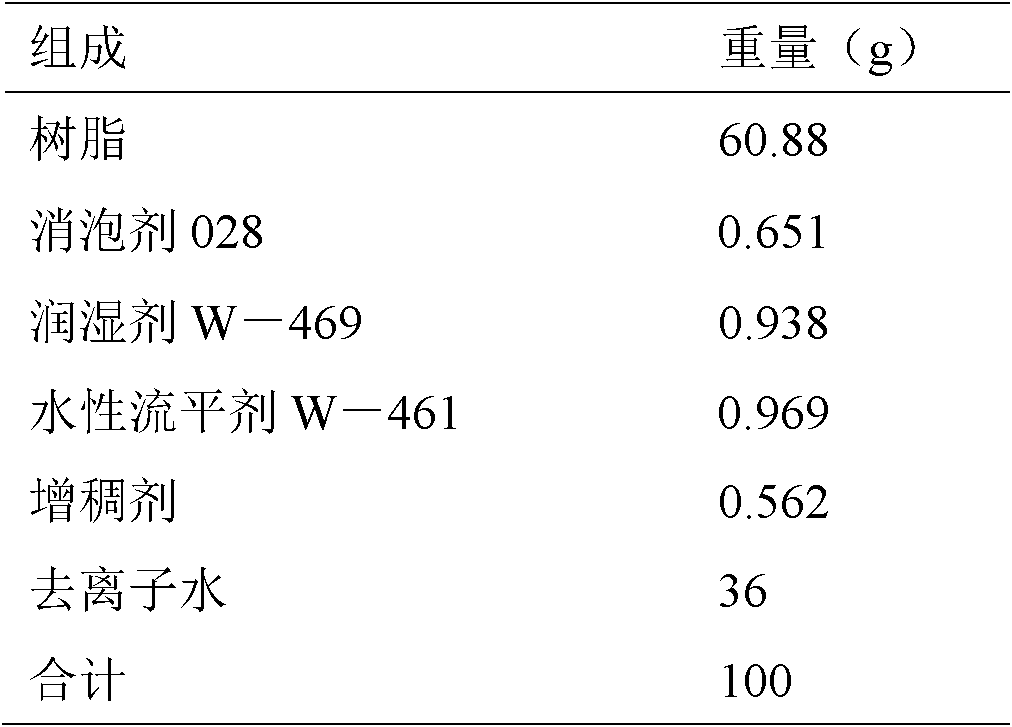

Examples

Embodiment Construction

[0033]The technical solution of the present invention is described in detail below. The embodiments of the present invention are only used to illustrate the technical solutions of the present invention without limitation. Although the present invention has been described in detail with reference to the preferred embodiments, those skilled in the art should understand that the technical solutions of the invention can be modified or equivalently replaced , without departing from the spirit and scope of the technical solution of the present invention, all of which shall be covered by the claims of the present invention.

[0034] The water-dispersed fluorine-containing hydroxyl acrylic acid-epoxy ester hybrid resin of the present invention provided by each of the following examples is prepared as follows:

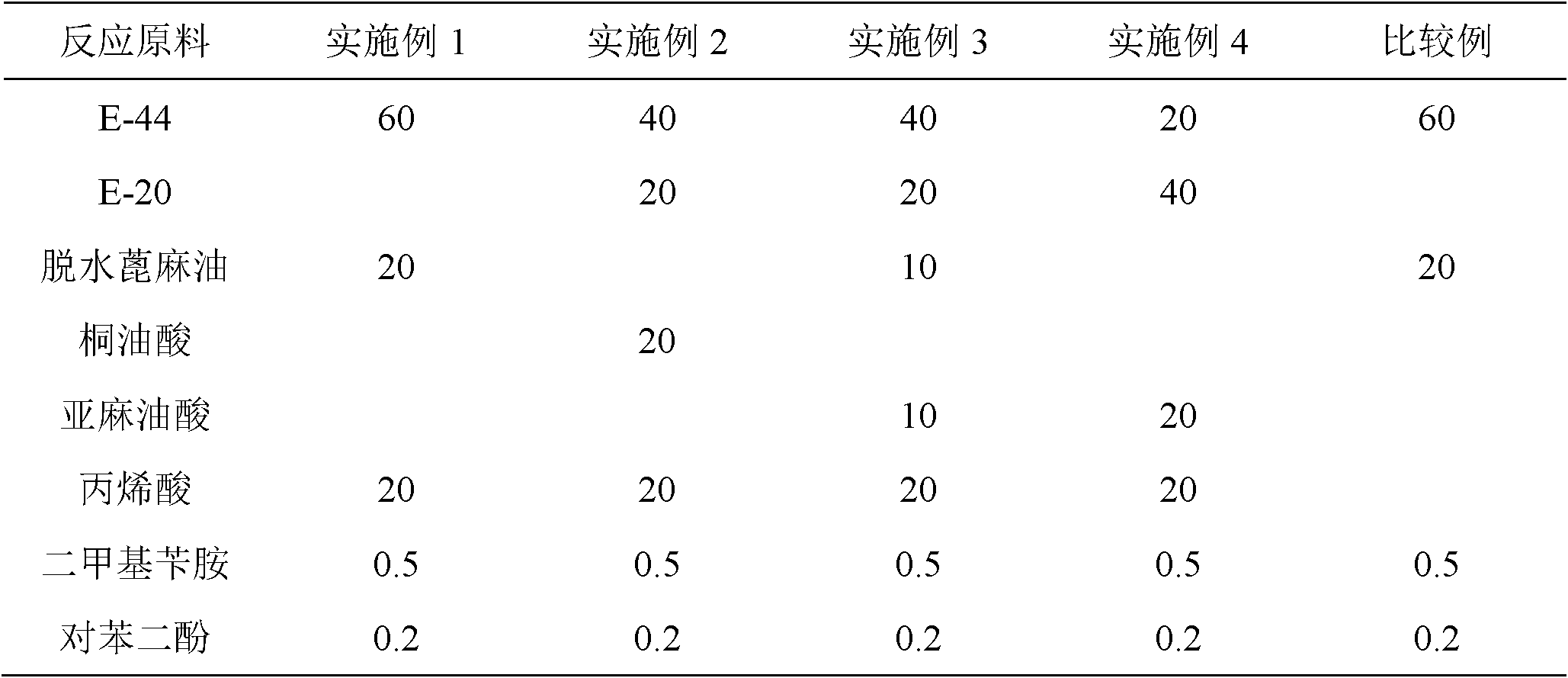

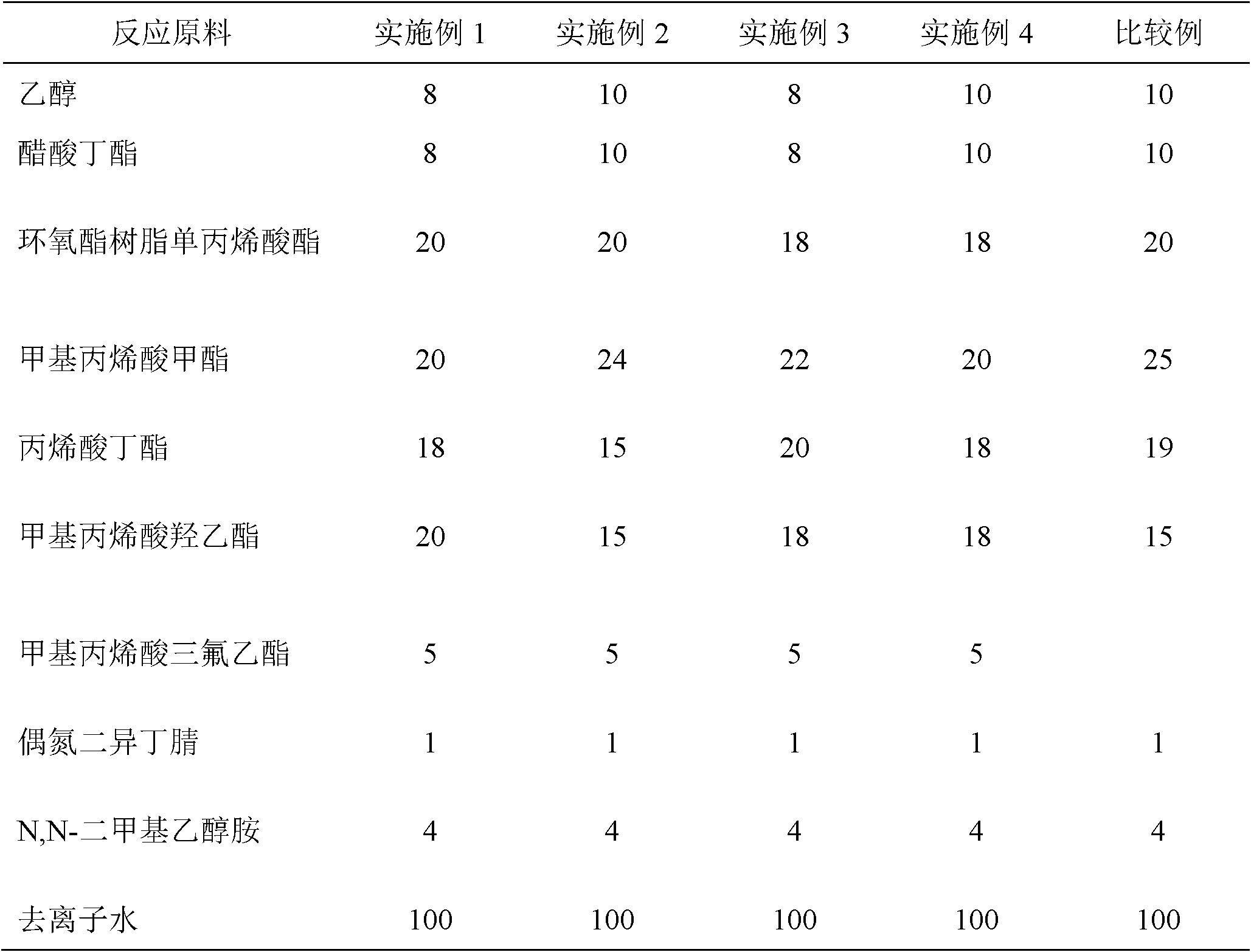

[0035] Step 1: Mix epoxy resin, fatty acid and acrylic acid and heat up. When the temperature rises to 100°C, add catalyst and polymerization inhibitor and keep warm. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com