Preparation method and forming fixture of membrane electrode of proton exchange membrane fuel cell

A proton exchange membrane and fuel cell membrane technology, applied in battery electrodes, manufacturing tools, circuits, etc., can solve problems such as cumbersome operations, expensive molding equipment, and increased production costs of proton exchange membrane fuel cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The embodiment of the invention discloses a method for preparing a membrane electrode of a gardenia exchange membrane fuel cell, comprising:

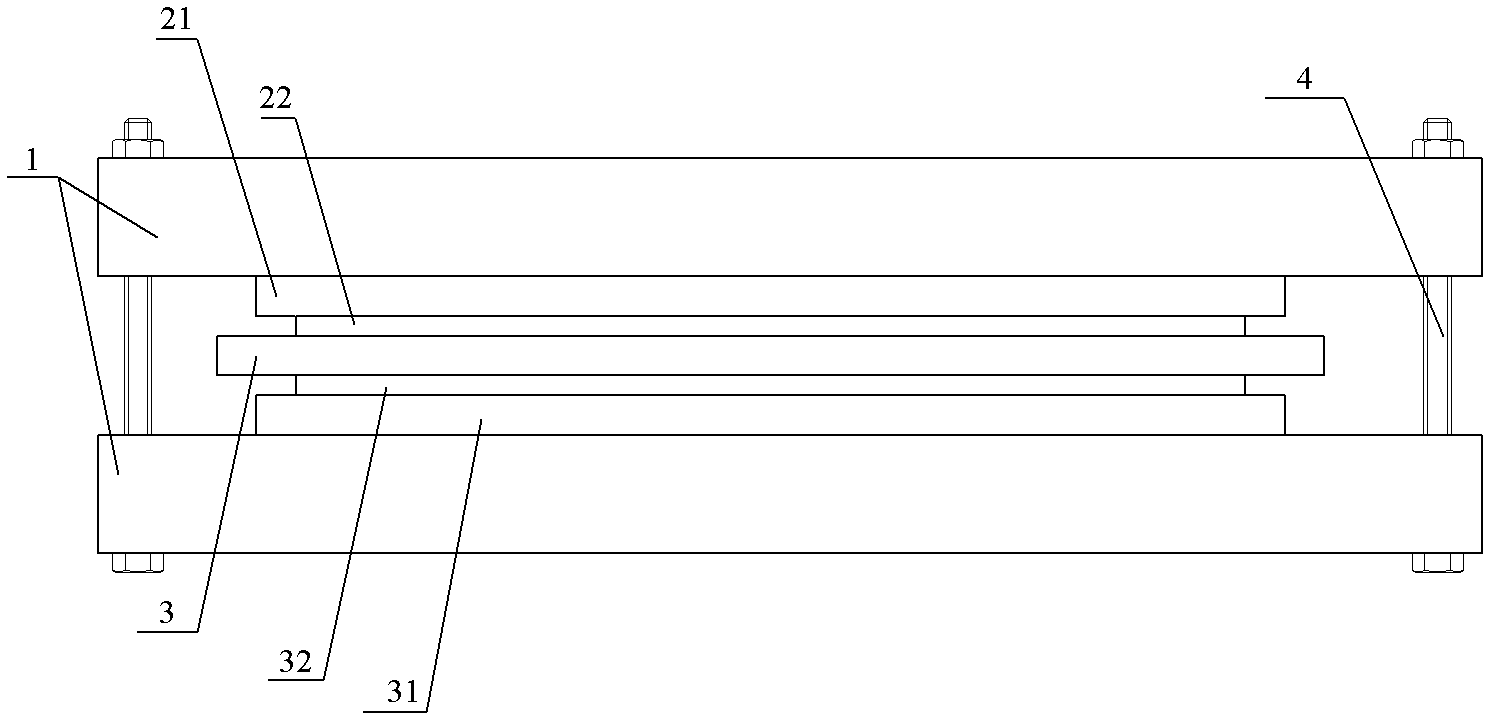

[0044] The catalyst anode layer, the proton exchange membrane layer and the catalyst cathode layer are sequentially stacked between two parallel flat plates; screw holes are provided on the flat plates, and the two flat plates are connected by bolts; the setting torque is 0.5N·m~ 5N·m, the relative positions are fixed after the two plates are pressed; the catalyst anode layer includes an anode diffusion layer and an anode catalyst layer covering the surface of the anode diffusion layer; the catalyst cathode layer includes a cathode diffusion layer and a coating layer a cathode catalyst layer on the surface of the anode diffusion layer;

[0045] Take out the fixed two plates, and the catalyst anode layer, proton exchange membrane layer and catalyst cathode layer between the two plates at 140°C to 300°C for 2min to 30min, remove th...

Embodiment 1

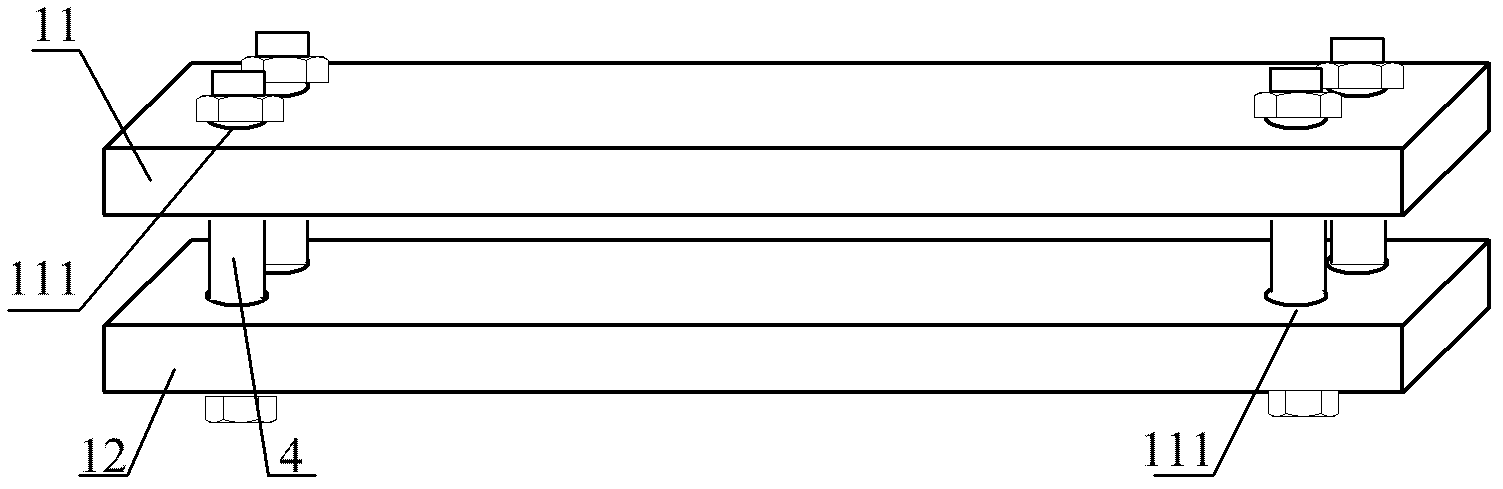

[0069] In a piece of 2×2cm 2 On the anode carbon paper, spray 3mg / cm 2 Platinum ruthenium black catalyst, on another sheet 2 x 2cm 2 On the cathode carbon paper, spray 3mg / cm 2 Platinum black catalyst, put these two carbon papers on a 3×3cm 2 On both sides of the Nafion117 membrane, the catalyst layer is in contact with the Nafion membrane, and then these membrane electrode assemblies are placed in figure 2 Between the two flat plates of the forming jig shown, the flat plates are made of steel plates, and the two flat plates are fixed by screws with a torque of 0.9 N·m.

[0070] The jig was heated in an oven at 200°C for 10 minutes, taken out, and cooled to obtain a membrane electrode.

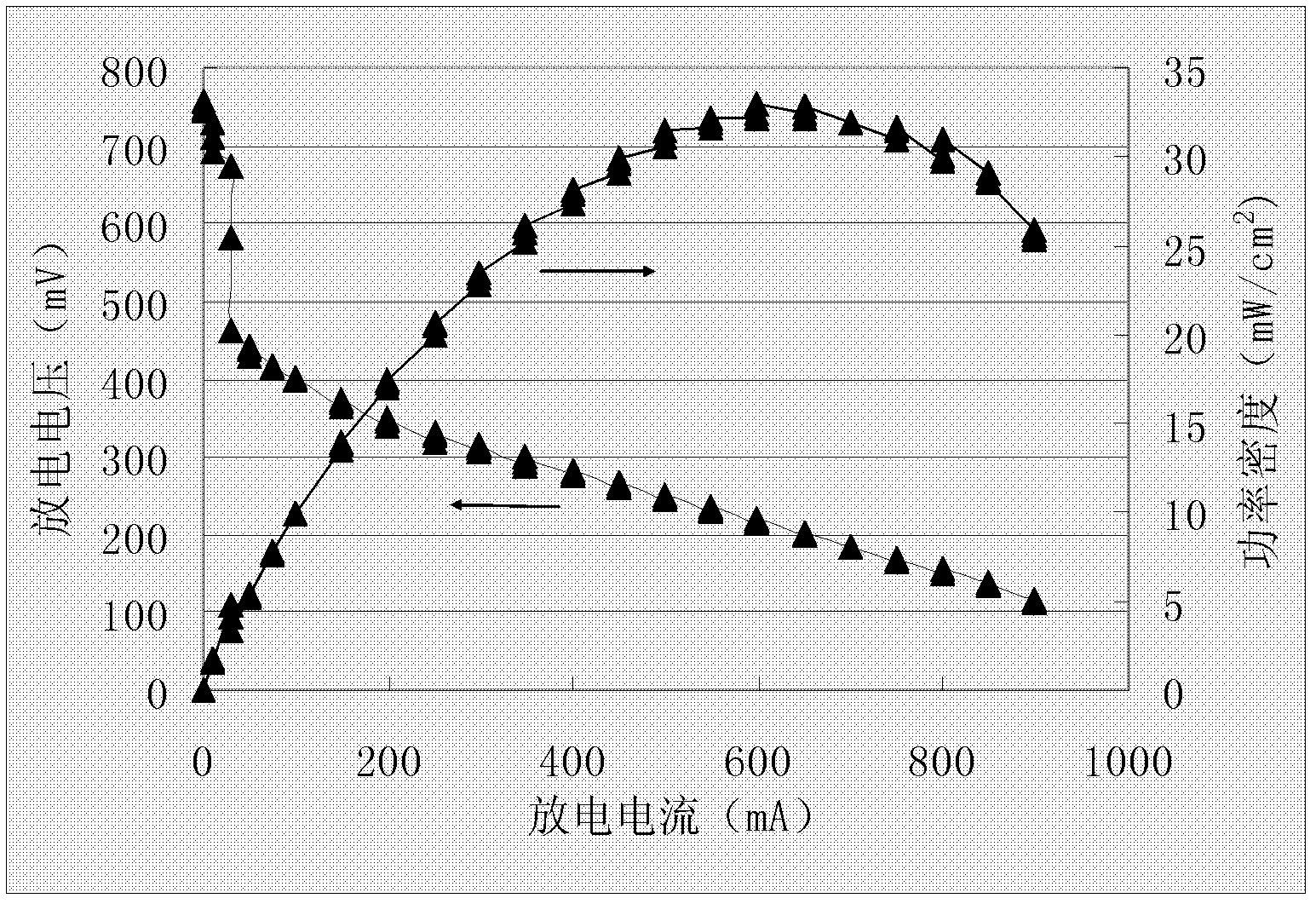

[0071] Install this membrane electrode in a self-breathing methanol fuel cell, test its performance at room temperature, the concentration of methanol is 3M, the test results are as follows image 3 shown. image 3 The voltage and power curves tested when the membrane electrode prepared...

Embodiment 2

[0073] In a piece of 2×2cm 2 On the anode carbon paper, spray 2mg / cm 2 Platinum ruthenium black catalyst, on another sheet 2 x 2cm 2 On the cathode carbon paper, spray 2mg / cm 2 Platinum black catalyst, put these two carbon papers on a 3×3cm 2 On both sides of the Nafion117 membrane, the catalyst layer is in contact with the Nafion membrane, and then these membrane electrode assemblies are placed in figure 2Between the two flat plates of the forming jig shown, the flat plates are made of steel plates, and the two flat plates are fixed by screws with a torque of 0.9 N·m.

[0074] The jig was heated in an oven at 220° C. for 8 minutes, taken out, and cooled to obtain a membrane electrode.

[0075] Install this membrane electrode in a self-breathing methanol fuel cell, test its performance at room temperature, the concentration of methanol is 3M, the test results are as follows Figure 4 shown. Figure 4 The voltage and power curves tested when the membrane electrode prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com