Liquid milk added with papaya puree and preparation method

A technology of adding wood to liquid milk, which is applied in the direction of milk preparations, dairy products, applications, etc., can solve problems such as easy coagulation and difficult storage, and achieve the effect of meeting taste needs and expanding sales range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

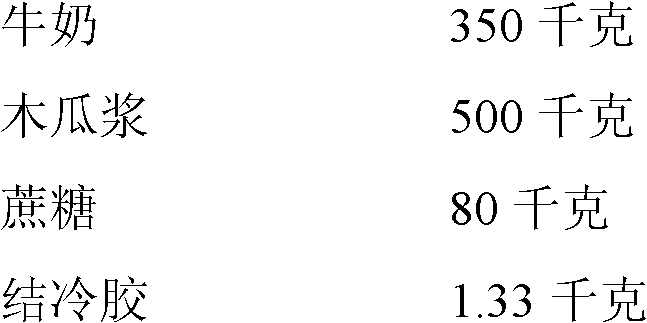

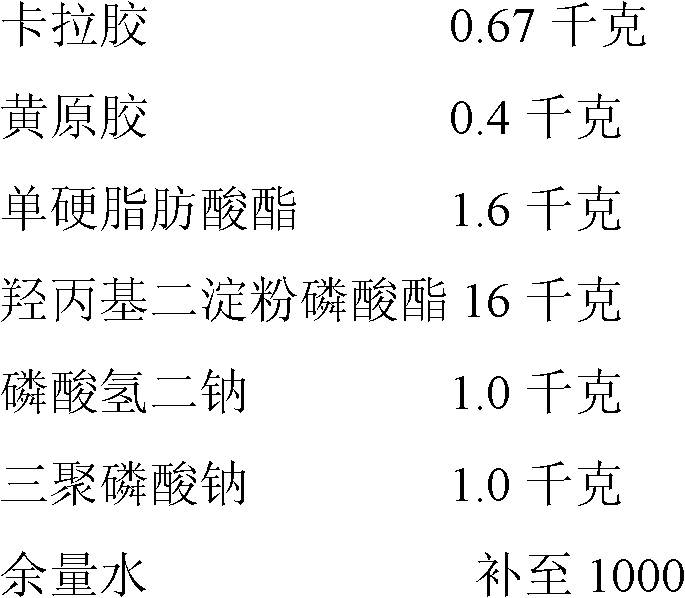

[0030] Formula (based on one ton of product):

[0031]

[0032]

[0033] Raw material standard:

[0034] Milk: protein ≥ 3.0%, fat ≥ 3.3%, dry matter ≥ 11.8%.

[0035] White granulated sugar: in line with the national first-class standard.

[0036] Pure water: in line with national standards.

[0037] Preparation of papaya pulp: papaya undergoes raw material acceptance, selection, crushing and beating, papaya pulp is pretreated, filtered, sterilized, and filled. Soluble solids ≥ 12.0%; pH: 4.3-4.5; normal aroma and color of papaya.

[0038] making process:

[0039] 1) Prepare the base material: a. Add the qualified milk into the chemical tank at 60-70°C, add sucrose, xanthan gum, monostearate, hydroxypropyl distarch phosphate, and put it in the high-speed shear pump Stir and keep warm for 15-25 minutes, cool at about 10°C and pour into the batching tank. b. Pour 20°C ingredients accounting for 10% of the batching amount into the chemical tank with water, add gellan...

Embodiment 2

[0045] Formula (based on one ton of product):

[0046]

[0047]

[0048] Raw material standard:

[0049] Milk: protein ≥ 3.0%, fat ≥ 3.3%, dry matter ≥ 11.8%.

[0050] White granulated sugar: in line with the national first-class standard.

[0051] Pure water: in line with national standards.

[0052] The preparation of papaya pulp: with embodiment 1.

[0053] Preparation process: the same as in Example 1, the only difference is that when preparing the base material in step 1), put the ingredients accounting for 30% of the batching amount at 30°C into the chemical tank with water, add gellan gum and carrageenan, and stir for 10-20 minutes. Minutes into the batching tank.

[0054] The product detection index that present embodiment provides: fat content is 1.70%, and protein content is 1.55%, and soluble solid is 12.5%, and the viscosity of this product that records at 20 ℃ with BROKFIELD DV-III type viscometer is about 33.2 centipoise, pH 6.9. The overall state of th...

Embodiment 3

[0056] Formula (based on one ton of product):

[0057]

[0058]

[0059] Raw material standard:

[0060] Milk: protein ≥ 3.0%, fat ≥ 3.3%, dry matter ≥ 11.8%.

[0061] White granulated sugar: in line with the national first-class standard.

[0062] Pure water: in line with national standards.

[0063] The preparation of papaya pulp: with embodiment 1.

[0064] Preparation process: with embodiment 1.

[0065] The product detection index that present embodiment provides: fat content is 1.70%, and protein content is 1.55%, and soluble solid is 14.0%, and the viscosity of this product that records at 20 ℃ with BROKFIELD DV-III type viscometer is about 33.2 centipoise, pH 7.6. The overall state of the product is uniform, and the taste is smooth and smooth when drinking, with the smooth taste of milk and the aroma of papaya.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com