Functional raw material added in smokeless tobacco products and method for preparing smokeless tobacco products

A smokeless tobacco, functional technology, applied in the direction of tobacco, tobacco processing, application, etc., can solve the problems of affecting the taste, difficult to meet the taste requirements of smokers, etc., so as to reduce the dependence on nicotine content, increase the richness, and ease the withdrawal from smoking. the effect of cessation of symptoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

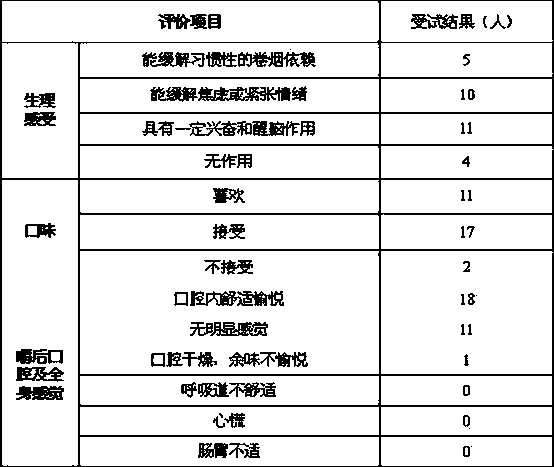

Image

Examples

Embodiment 1

[0024] Mix 10g of tobacco powder, 10g of coffee powder, 50g of betel nut powder, and 3g of essence to prepare a functional raw material. When applying this functional raw material to the preparation of smokeless tobacco products, first weigh 100g of gum base, 112g of xylitol, 10g of maltitol, and 5g of glycerin, mix them evenly, heat and stir at 70-80°C to obtain the base material, and then The functional raw materials are added into the base material and mixed evenly, and 300 g of cylindrical smokeless tobacco chewing gum with a length of 8.4 cm and a diameter of 0.8 cm are made through processes such as tableting, molding, and polishing.

Embodiment 2

[0026] Mix 10g of smoke powder, 50g of coffee powder, 10g of betel nut powder, and 3g of essence to prepare a functional raw material. When applying this functional raw material to the preparation of smokeless tobacco products, first weigh 100g of gum base, 112g of xylitol, 10g of maltitol, and 5g of glycerin, mix them evenly, heat and stir at 70-80°C to obtain the base material, and then The functional raw materials are added into the base material and mixed evenly, and 300 g of cylindrical smokeless tobacco chewing gum with a length of 8.4 cm and a diameter of 0.8 cm are made through processes such as tableting, molding, and polishing.

Embodiment 3

[0028] 2g of tobacco extract, 5g of coffee powder, 80g of areca nut extract, and 2g of essence are uniformly mixed to prepare a functional raw material. When preparing smokeless tobacco products, first weigh 100g of xylitol, 100g of polygrape, and 11g of erythritol, mix them evenly, heat and stir at 70~80°C to make a base material, and then add functional materials into the base material and mix Uniformly, 300 g of smokeless tobacco lozenges are made through processes such as granulation and tabletting.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com