Production method for smoke extraction tube in kitchen

A production method and kitchen technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of uneven thickness of the smoke exhaust pipe wall, shortened service life of the pipe, and potential safety hazards, and achieve reliable fire safety performance and long service life Growth, the effect of not easily absorbing oil stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] The material adopts the following weight percentage formula: magnesium chloride 10%, magnesium oxide 20%, gypsum powder 15%, perlite or quartz sand or water sand 15%, fiber material 3%, sawn wood 5%, water 22%, filler 10% ;

[0017] Mix the above ingredients;

[0018] Using the production method of inner mold and outer mold, the ingredients are molded, demoulded at one time, and then dried;

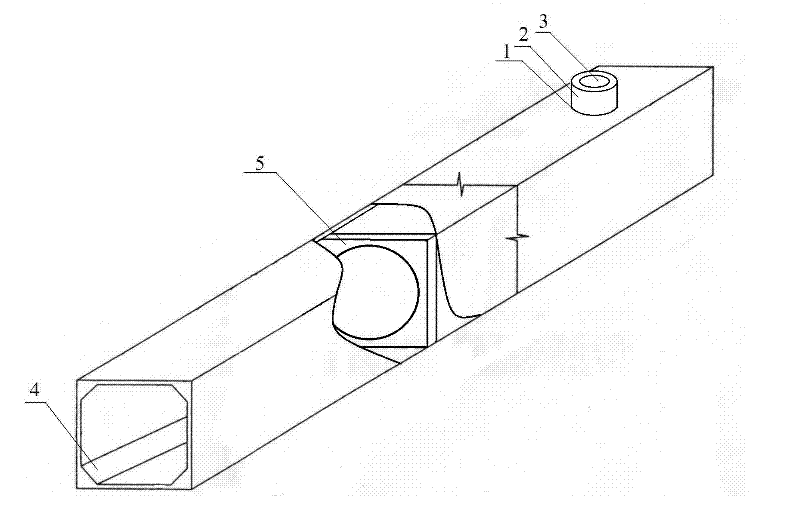

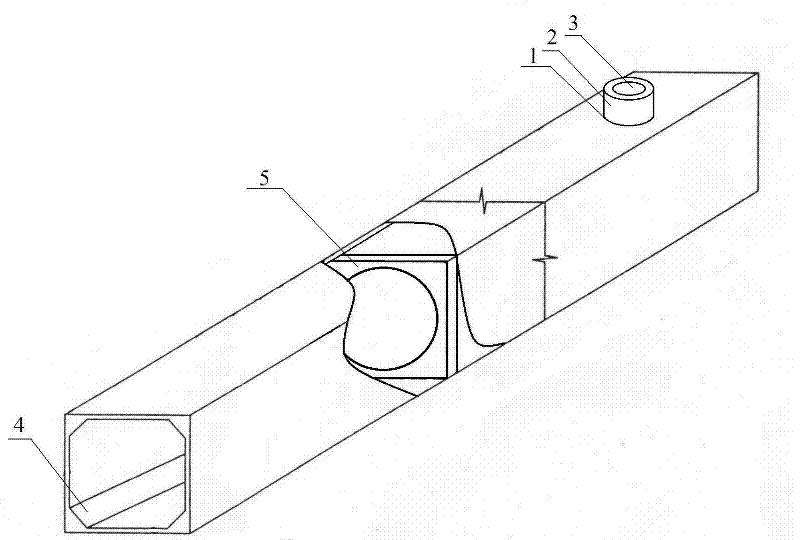

[0019] See figure 1 , the overall cylindrical structure with a rectangular frame cross section obtained by the above-mentioned demoulding, the thickness of the wall pipe of the cylinder body is 15mm, and a chamfer 4 is provided at the right angle of the inner wall of the smoking pipe, the purpose is to eliminate the internal chamfer of the pipe wall. Stress, there is an introduction hole 1 for a fixed connection pipe on the smoke pipe, and a connection pipe 2 is inserted into the hole during assembly. The connection pipe is used to connect with the smoke introduction pipe sleeve ...

Embodiment 2

[0021] The material adopts the following weight percentage formula: magnesium chloride 8%, magnesium oxide 25%, gypsum powder 15%, perlite or quartz sand or water sand 14%, fiber material 2%, sawn wood 5%, water 21%, filler 10% ;

[0022] Mix the above ingredients;

[0023] Using the production method of inner mold and outer mold, the ingredients are molded, demoulded at one time, and then dried;

[0024] The overall cylindrical structure with a rectangular frame cross-section obtained by the above-mentioned demoulding, the thickness of the wall tube of the cylinder is 8 mm, and chamfers are provided at the right angles of the inner wall of the smoke pipe.

Embodiment 3

[0026] The material adopts the following weight percentage formula: magnesium chloride 12%, magnesium oxide 25%, gypsum powder 13%, perlite or quartz sand or water sand 14%, fiber material 2%, sawn wood 3%, water 20%, filler 12% %;

[0027] Mix the above ingredients;

[0028] Using the production method of inner mold and outer mold, the ingredients are molded, demoulded at one time, and then dried;

[0029] The overall cylindrical structure with a rectangular frame cross section obtained by the above-mentioned demoulding, the thickness of the wall pipe of the cylinder body is 12mm, and chamfers are provided at the right angles of the inner wall of the smoking pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com