Preparation method for Ag-Al co-doped p type ZnO film

A co-doping, p-type technology, applied in the field of chemistry and chemical engineering, can solve the problems that the p-n structure of the core components of semiconductor devices cannot be produced, the development and application of photoelectric components are limited, and it is difficult to realize p-type transformation, so as to achieve easy control, The effect of good appearance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

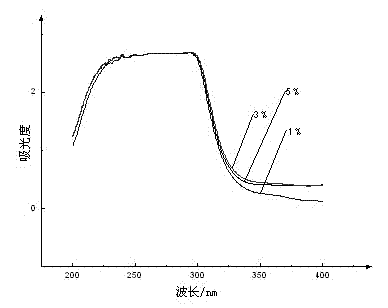

Image

Examples

Embodiment 1

[0029] (1) Dissolve zinc acetate dihydrate in absolute ethanol to a concentration of 0.5mol / L, then add diethanolamine as a stabilizer according to the molar ratio of diethanolamine and zinc ions to 1:1, to obtain a mixed solution;

[0030] (2) Stir the mixed solution obtained in step (1) at 70°C for 30 minutes, and then press Ag + and A1 3+ accounted for Zn 2+ The mass percentage is 1% adding aluminum nitrate nonahydrate and silver nitrate, wherein Ag in aluminum nitrate nonahydrate and silver nitrate + : A1 3+ The mass ratio is 4:1, and stirring is continued for 45 minutes at 72°C;

[0031] (3) Aging the solution obtained in step (2) for 24 hours to make the solution form a sol;

[0032] (4) Clean the substrate material quartz glass with 30% hydrogen peroxide;

[0033] (5) Coating the sol obtained in step (3) on the cleaned substrate material in step (4) by using a spin coating method with a spin coating speed of 1000 rpm;

[0034] (6) Heat the coated substrate materia...

Embodiment 2

[0037] (1) Dissolve zinc acetate dihydrate in absolute ethanol to a concentration of 2mol / L, then add diethanolamine as a stabilizer according to the molar ratio of diethanolamine and zinc ions to 1:1, to obtain a mixed solution;

[0038] (2) Stir the mixed solution obtained in step (1) at 72°C for 40 minutes, and then press Ag + and A1 3+ accounted for Zn 2+ The mass percentage is 3% adding aluminum nitrate nonahydrate and silver nitrate, wherein Ag in aluminum nitrate nonahydrate and silver nitrate + : A1 3+ The mass ratio is 4:1, and stirring is continued for 30 minutes at 75°C;

[0039] (3) Aging the solution obtained in step (2) for 12 hours to make the solution form a sol;

[0040] (4) Clean the substrate material glass with 10% dilute hydrochloric acid;

[0041] (5) Coating the sol obtained in step (3) on the cleaned substrate material in step (4) by dipping and pulling at a pulling speed of 3 cm / min;

[0042] (6) Heat the coated substrate material obtained in step ...

Embodiment 3

[0045] (1) Dissolve zinc acetate dihydrate in absolute ethanol to a concentration of 1.5mol / L, then add diethanolamine as a stabilizer according to the molar ratio of diethanolamine and zinc ions to 1:1, to obtain a mixed solution;

[0046] (2) Stir the mixed solution obtained in step (1) at 75°C for 45 minutes, and then press Ag + and A1 3+ accounted for Zn 2+ The mass percentage is 5% adding aluminum nitrate nonahydrate and silver nitrate, wherein Ag in aluminum nitrate nonahydrate and silver nitrate + : A1 3+ The mass ratio is 4:1, and stirring is continued for 40 minutes at 70°C;

[0047] (3) Aging the solution obtained in step (2) for 20 hours to make the solution form a sol;

[0048] (4) Clean the substrate material quartz glass with 10% dilute sulfuric acid;

[0049] (5) Coating the sol obtained in step (3) on the cleaned substrate material in step (4) by using a spin coating method with a spin coating speed of 1600 rpm;

[0050] (6) Heat the coated substrate mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com