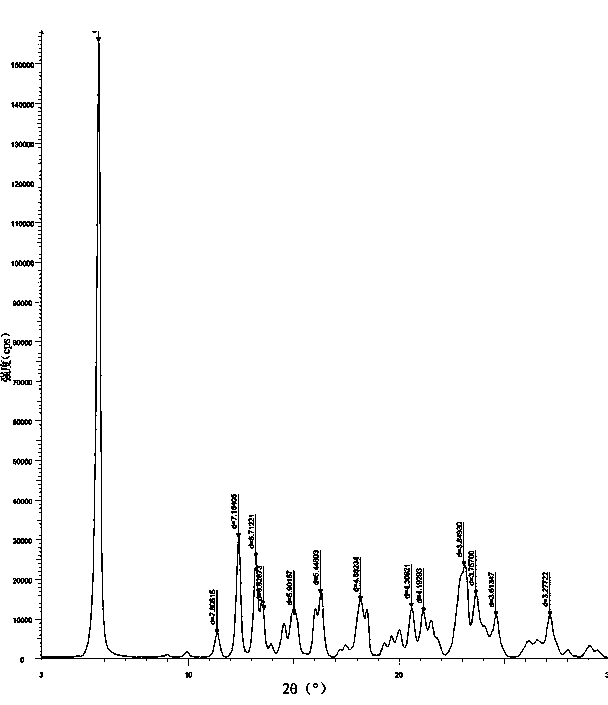

Azelnidipine crystal form, preparation method for same and officinal composition thereof

A technology of Azhedipine and crystal form, which is applied in the field of medicine, can solve the problems of unfavorable production operation and high static electricity of Azhedipine α crystal form, and achieve the effect of small electrostatic interaction, simple production operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

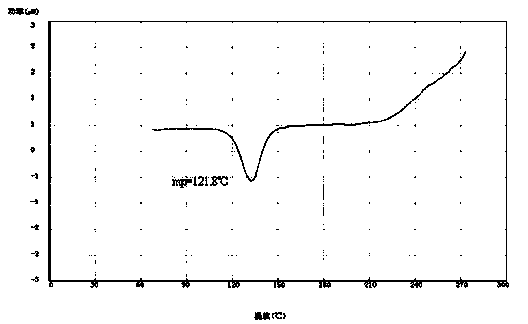

[0023] Thoroughly mix 10 g of amorphous azedipine with 40 ml of toluene, and heat to 30-40°C. Then add 2 to 3 g of activated carbon, stir and filter, add 40 ml of cyclohexane to the filtrate while stirring, continue to stir and crystallize, filter and dry to obtain 9.5 g of the new crystal form of azedipine, with a yield of 95% and a melting point of 163.4°C.

[0024] Heating to 40-50°C, and performing the same operations as above to obtain 9.4 g of the new crystal form of azelnidipine, with a yield of 94% and a melting point of 162.1°C.

[0025] Heating to 50-60°C, and performing the same operations as above to obtain 9.4 g of the new crystal form of azelnidipine, with a yield of 94% and a melting point of 162.7°C.

[0026] The above test proves that the heating and dissolving temperature ranges from 30 to 60°C. The higher the heating temperature, the longer the required crystallization time, so the preferred temperature is 30-40°C.

Embodiment 2

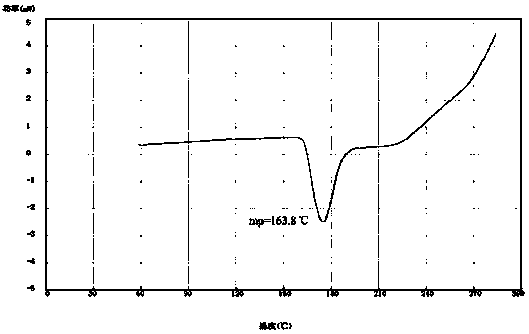

[0028] Thoroughly mix 10 g of amorphous azedipine with 40 ml of toluene, and heat to 30-40°C. Then add 2 to 3 g of activated carbon, stir and filter, add 40 ml of cyclohexane to the filtrate while stirring, continue to stir and crystallize, filter and dry to obtain 9.5 g of the new crystal form of azedipine, with a yield of 95% and a melting point of 163.8°C.

[0029] Using 50ml of toluene and 50ml of cyclohexane each, the rest was the same as above to obtain 9.4g of the new crystal form of azelnidipine, with a yield of 94% and a melting point of 163.7°C.

[0030] Using 60ml each of toluene and cyclohexane, the rest was the same as above to obtain 9.3g of the new crystal form of azeldipine, with a yield of 93% and a melting point of 162.2°C.

[0031] The above experimental results show that: for 10 g of amorphous azedipine, the preferred dosage of toluene is 40-60 ml. Experimental studies have found that when 10g of azeldipine is mixed with 40-60ml of toluene, the concentrati...

Embodiment 3

[0033] Thoroughly mix 10 g of amorphous azedipine with 40 ml of toluene, and heat to 30-40°C. Then add 2 to 3 g of activated carbon, stir and filter, add 20 ml of cyclohexane to the filtrate while stirring, continue to stir and crystallize, filter and dry to obtain 8.9 g of the new crystal form of azedipine with a yield of 89% and a melting point of 164.1°C.

[0034] 40ml of cyclohexane was added, and the rest was performed as above to obtain 9.5g of the new crystal form of azeldipine, with a yield of 95% and a melting point of 163.1°C.

[0035] 80ml of cyclohexane was added, and the rest was the same as above to obtain 9.6g of the new crystal form of azeldipine, with a yield of 96% and a melting point of 162.9°C.

[0036] The above experimental results show that the volume ratio of cyclohexane to toluene is 1:2 to 2:1, preferably an equal volume ratio. Too little cyclohexane will cause the yield to decrease, and when it reaches 1:1, the new crystal form of azeldipine is almo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com