Method for pressing Cyperus esculentus oil at ultralow temperature and pressing equipment thereof

A technology of ultra-low temperature and oily bean oil, which is applied in presses, fat oil/fat production, and fat production, etc. It can solve the problems that cannot meet the production requirements of oily oil, chemical solvents have potential safety hazards, and solvents are harmful to human health. High work efficiency, low production cost, good oil quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

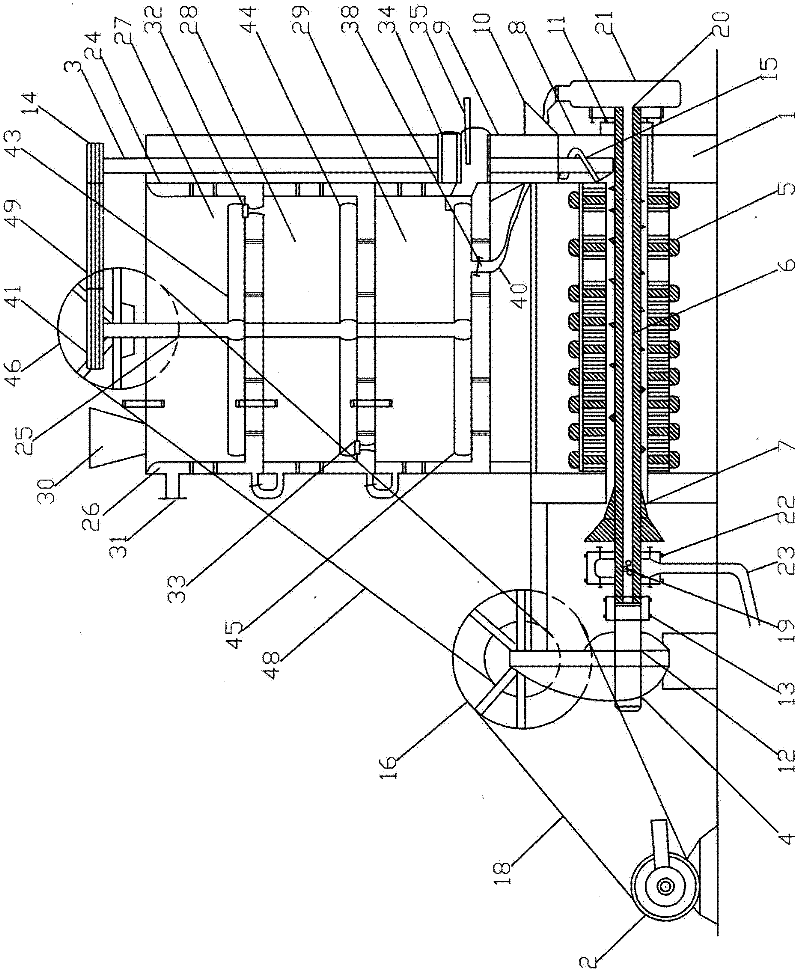

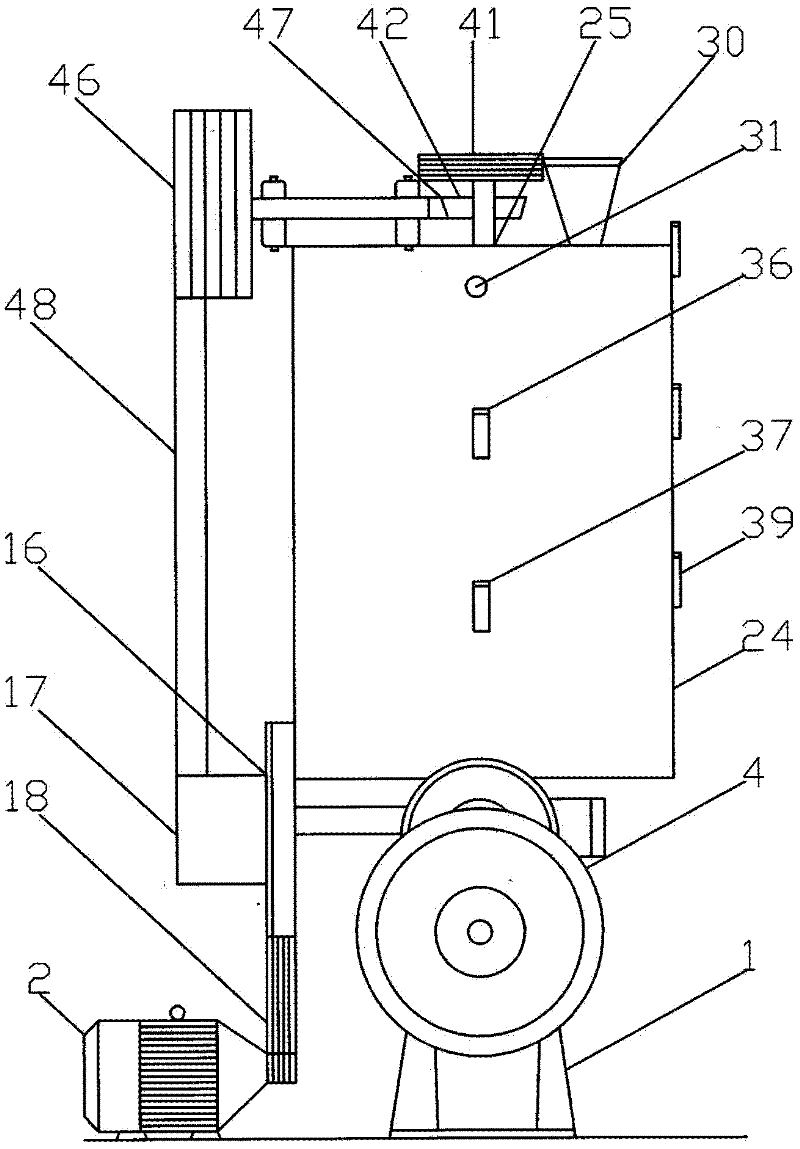

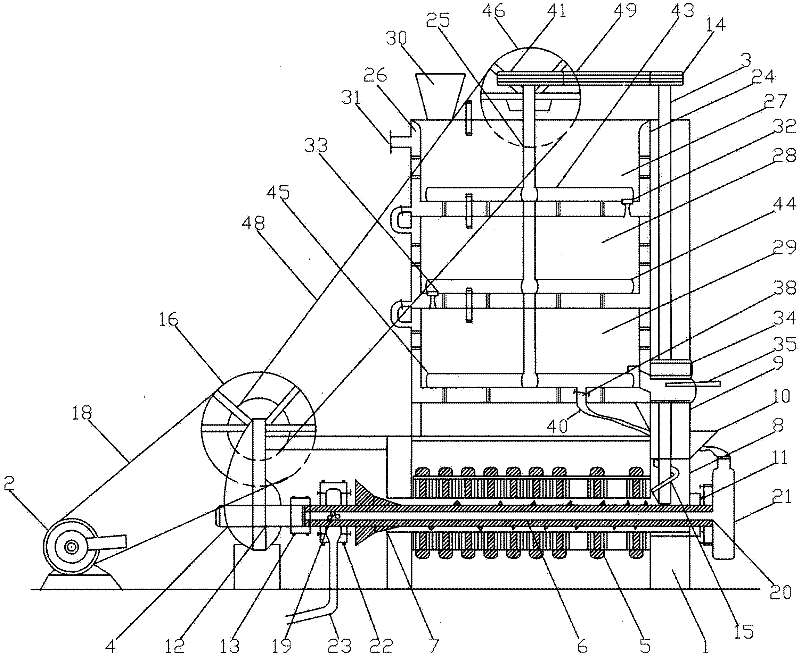

[0036] The method for ultra-low temperature pressing oily bean oil of the present invention adopts the following steps:

[0037] a) removing impurities and sorting to remove impurities such as stones and clods mixed in the fruit of the oily bean, and then washing the bean with water to clean off the silt attached to the skin of the fruit of the bean;

[0038] b) Drying material: drying the washed oily beans, and keeping the water content in the fruit of the dried oily beans at 12%;

[0039] C) Powder: send the dried oily bean fruit into a pulverizer with a mesh size of 2.5mm×2.5mm to be pulverized into coarse grains;

[0040] d) Steaming material Add 7% water of material weight to the pulverized oily bean material, send it into a steamer and steam and fry at a temperature of 80°C to soften, and steam and fry for 12 minutes;

[0041] e) Ultra-low temperature pressing. The steamed and fried softened material is sent to the cooling device of the special pressing equipment of the p...

Embodiment 2

[0052] In the drying step b), the water content in the dried oily bean fruit is 14%; in the powder step c), the mesh size of the pulverizer screen is 2mm×3mm; in the steaming step d), oil is added before steaming and frying The moisture in the Shadou material is 6% of the material weight, the steaming and frying temperature is maintained at 85° C., and the steaming and frying time is 11 minutes; the weight ratio relationship between urea and water in the urea cooling liquid in the ultra-low temperature pressing step e) is 1.2: 100, the temperature of the press chamber is maintained at 25°C; during the three-stage cooling process, the temperature to be lowered at each stage is: the first stage is 46°C, the second stage is 28°C, and the third stage is 6°C. All the other are with embodiment 1.

Embodiment 3

[0054] In step d) of steaming, add the water in the oily bean material before steaming and frying to 8% of the weight of the material, keep the temperature of steaming and frying at 75°C, and the time of steaming and frying is 14 minutes; The weight ratio relationship with water is 0.5:100, and the temperature of the press chamber is kept at 15°C; during the three-stage cooling process, the temperature to be lowered at each stage is: the first stage is 52°C, the second stage is 22°C, and the third stage is 8°C. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com