Plasma device for pretreatment of cotton woven fabric

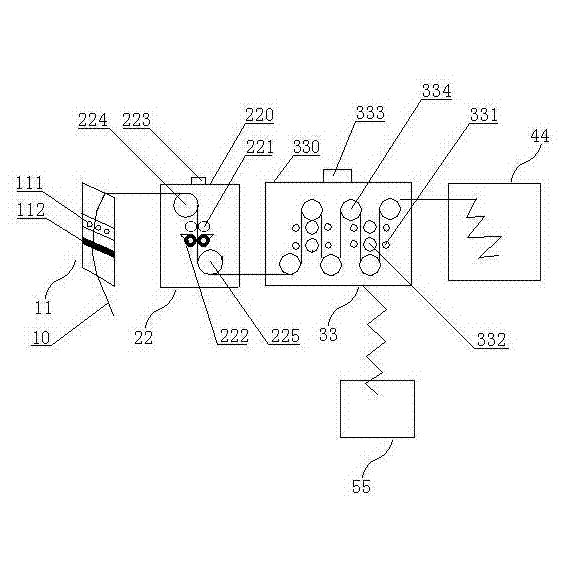

A plasma and woven fabric technology, applied in physical treatment, fiber treatment, plant fiber and other directions, can solve problems such as insufficient discharge intensity and production safety accidents, achieve uniform discharge, reduce production safety hazards, and achieve excellent results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

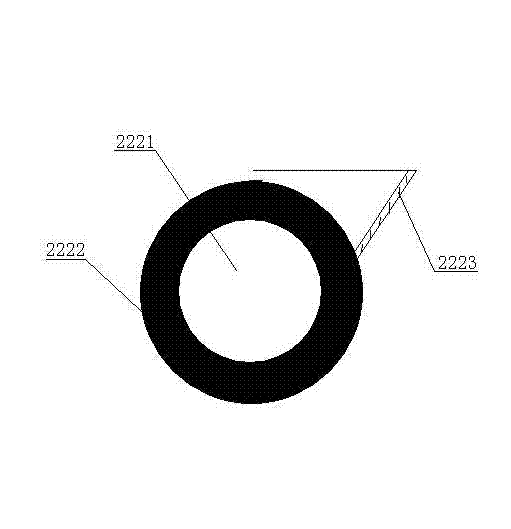

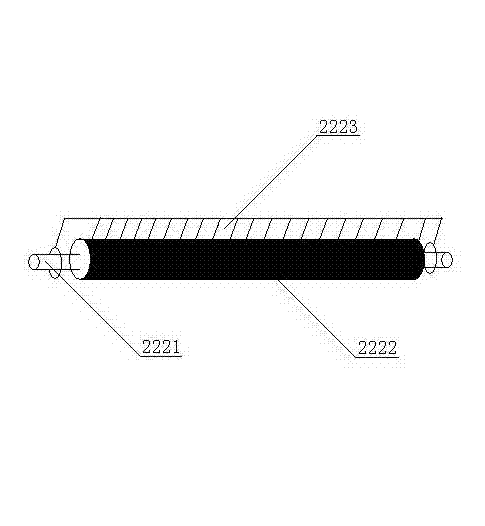

Method used

Image

Examples

Embodiment 1

[0034] Woven fabric: cotton gauze, 20 warp yarns, 16 weft yarns; warp density 128 yarns / 10cm, weft density 60 yarns / 10cm.

[0035] Plasma treatment parameters:

[0036] The discharge gap is 3 mm, the high voltage output is 80,000 volts, the operating frequency of the discharge device is 20 kHz, and the plasma processing time is 20 seconds.

[0037] Woven fabric deboiling process:

[0038] The dosage of alkali agent (sodium hydroxide) is 35 g / L, which is 30% lower than the conventional dosage; the steaming time is 60 minutes, which is 33% lower than the conventional dosage.

[0039] Result: capillary effect, 3 cm higher than normal in 30 minutes. The strength of the fabric is 58cm / 10cm higher in the warp direction and 30cm / 10cm higher in the weft direction. Wastewater chemical oxygen demand (COD), 22% lower than conventional

Embodiment 2

[0041] Woven fabric: cotton gauze, 20 warp yarns, 16 weft yarns; warp density 128 yarns / 10cm, weft density 60 yarns / 10cm.

[0042] Plasma treatment parameters: discharge gap 3 mm, high voltage output 100,000 volts, discharge device operating frequency 50 kHz, plasma treatment time 30 seconds.

[0043] Woven fabric deboiling process: the dosage of alkali agent (sodium hydroxide) is 25 g / L, which is 50% lower than the conventional dosage; the steaming time is 45 minutes, which is 50% lower than the conventional dosage.

[0044] Result: capillary effect, consistent with routine within 30 minutes. The strength of the fabric is 65cm / 10cm higher in the warp direction and 32cm / 10cm higher in the weft direction. The chemical oxygen demand (COD) of wastewater is 36% lower than the conventional one.

Embodiment 3

[0046] Woven fabric: cotton fine canvas, warp yarn 32 / 2, weft 16; warp density 96 / 10cm, weft density 82 / 10cm.

[0047] Plasma treatment parameters: discharge gap 2 mm, high voltage output 100,000 volts, discharge device operating frequency 50 kHz, plasma treatment time 30 seconds.

[0048] Woven fabric deboiling process: the amount of alkali agent (sodium hydroxide) is 30 g / L, which is 50% lower than the conventional amount. The steaming time is 55 minutes, which is 45% lower than the conventional dosage.

[0049] Result: capillary effect, 1 cm higher than normal in 30 minutes. The strength of the fabric is 45cm / 10cm higher in the warp direction and 12cm / 10cm higher in the weft direction. The chemical oxygen demand (COD) of wastewater is reduced by 38% compared with the conventional one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com