Wet type friction clutch disc material for transmitting high power and preparation process

A clutch, high-power technology, applied in the direction of friction lining, mechanical equipment, etc., can solve the problems of insignificant effect, the performance of C/C composite materials cannot meet the requirements, etc., to improve the ability of shear resistance, improve hardness, The effect of increasing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

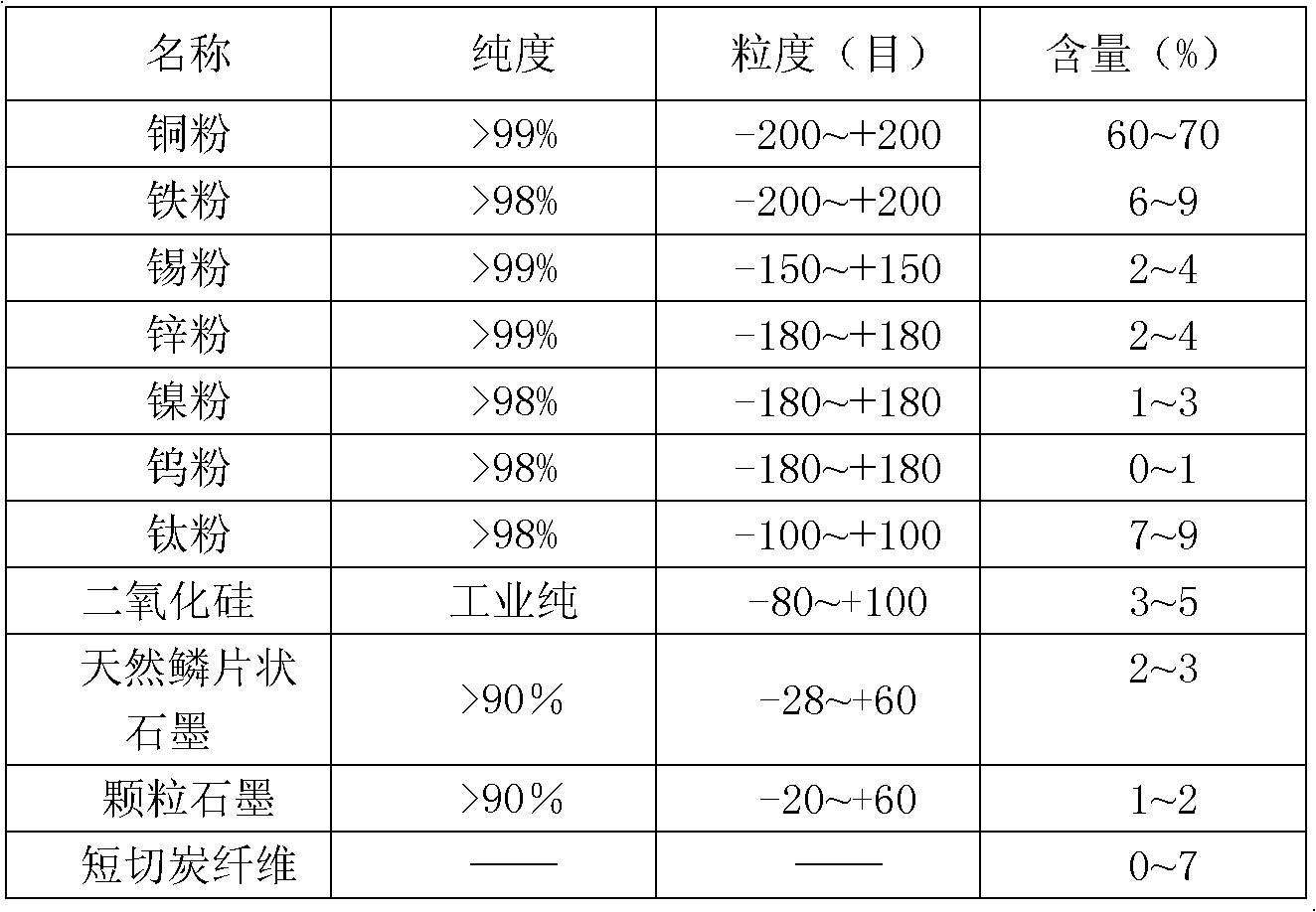

Embodiment 1

[0025] First, according to the mass percentage of alloy elements: Cu 62.8%, Fe 8%, Sn 3%, Zn 3%, Ni 2%, Ti 8.5%, SiO 2 4%, C 3.5%, W 0.2%, chopped carbon fiber T700, 5%, and forming agent (kerosene) to prepare a mixture, and the mixture is mixed with the powder in a roller ball mill for 6-8 hours; the mixture is cooled under a pressure of 500MPa Press molding, then paste the green compact and the supporting steel back and put it in a bell-type heating and sintering furnace for pressure sintering, and carry out pressure sintering under the protection of hydrogen. The sintering temperature is 920 ° C, the sintering pressure is 4.5 MPa, and the holding time is 3h. Water-cooled to room temperature and out of the furnace; after quenching the sintered parts at 800 °C, pressurized tempering at a temperature of 550 °C and a pressure of 5 MPa to achieve a certain hardness of the supporting steel back (HRC35-38), and the sintered parts were vacuum At a temperature of -0.2MPa and a tem...

Embodiment 2

[0027] First, according to the mass percentage of alloy elements: Cu 61.5%, Fe 8%, Sn 3%, Zn 3%, Ni 2%, Ti 8.5%, SiO 2 4%, C 3.5%, W 0.5%, chopped carbon fiber T700, 6% and forming agent to prepare alloy raw materials, and mix the powder in a roller ball mill for 6-8 hours; the mixture is cold-pressed under 700MPa pressure, and then The green compact and the supporting steel back were pasted and placed in a bell-type heating and sintering furnace for pressure sintering, under the protection of hydrogen, the sintering temperature was 900 °C, the sintering pressure was 3.5 MPa, and the holding time was 3 h. After water-cooling to room temperature, the sintered parts are quenched at 800 ° C, and then tempered under pressure at a temperature of 550 ° C and a pressure of 5 MPa to achieve a certain hardness (HRC35-38) of the supporting steel back. The temperature is -0.2MPa, the temperature is 500℃, impregnate the phenolic resin for high temperature resistant brake pads for 30 minu...

Embodiment 3

[0029] First, according to the mass percentage of alloy elements: Cu 64.5%, Fe 8%, Sn 3%, Zn 3%, Ni 2%, Ti 8.5%, SiO 2 4%, C 3.5%, W 0.5%, chopped carbon fiber T700, 3%, and forming agent to prepare alloy raw materials, and mix the powder in a roller ball mill for 6-8 hours; the mixture is cold-pressed under 700MPa pressure, and then The green compact and the supporting steel back were pasted together and placed in a bell-type heating and sintering furnace for pressure sintering. Under the protection of hydrogen, pressure sintering was carried out. The sintering temperature was 900°C, the sintering pressure was 3.0 MPa, and the holding time was 3 hours. After water-cooling to room temperature, the sintered parts are quenched at 850 °C, and then tempered under pressure at a temperature of 550 °C and a pressure of 7 MPa to achieve a certain hardness (HRC35-38) on the supporting steel back. The temperature is -0.2MPa, the temperature is 500℃, impregnate the phenolic resin for hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com