Dual-cation bactericide, preparation method and application thereof

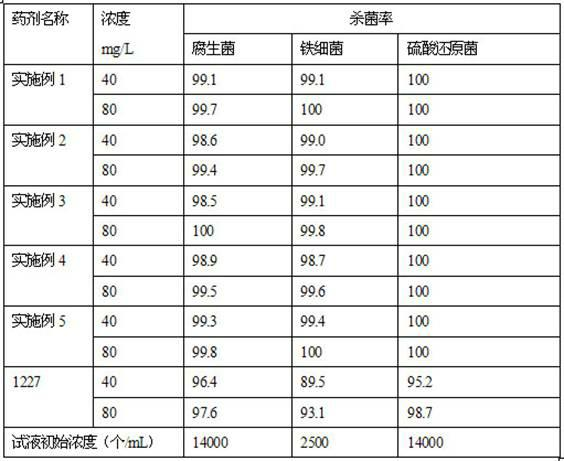

A dual-cation, fungicide technology, applied in the fields of botanical equipment and methods, biocides, chemical instruments and methods, etc., can solve the problems of decreased bactericidal effect, environmental pollution, emergence of drug resistance, etc. Easy to source, good sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

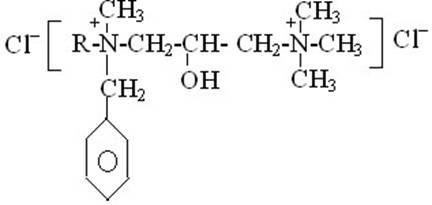

Method used

Image

Examples

Embodiment 1

[0017] will be 3m 3 Add 1130kg water in the reactor, start stirring. Then add 217kg of tetradecylmethyl secondary amine, start to heat up to 50-55°C, slowly add 93kg of epichlorohydrin, keep the temperature at 60-65°C for 5h, cool down to 40-45°C, add 127kg of hydrochloric acid, add 62kg Trimethylamine, raise the temperature and keep the temperature at 60-65°C for 2.5h. Cool down to 40-45°C, slowly add 124kg of benzyl chloride into the reaction kettle, raise the temperature, keep the temperature at 70-85°C for 5 hours, and finally obtain a colorless or light yellow tetradecyl dicion quaternary compound with a content of 36%. Ammonium salt fungicide products.

Embodiment 2

[0019] will be 3m 3 Add 1300kg water in the reactor, start stirring. Then add 241kg of hexadecylmethyl secondary amine, start to heat up to 50-55°C, slowly add 97kg of epichlorohydrin, keep the temperature at 60-65°C for 6h, cool down to 40-45°C, add 131kg of hydrochloric acid, add 61kg Trimethylamine, raise the temperature and keep the temperature at 60-65°C for 3h. Cool down to 40-45°C, slowly add 127kg of benzyl chloride into the reaction kettle, raise the temperature, keep the temperature at 70-85°C for 6.5 hours, and finally obtain a colorless or light yellow hexadecyl dianion with a content of 34%. Quaternary ammonium fungicide products.

Embodiment 3

[0021] will be 3m 3 Add 1300kg water in the reactor, start stirring. Then add 79 kg of dodecylmethyl secondary amine and 146 kg of tetradecylmethyl secondary amine, start to heat up to 50-55 °C, slowly add 101 kg of epichlorohydrin, keep the temperature at 60-65 °C for 4 hours, and cool down Add 133kg of hydrochloric acid to 40-45°C, add 67kg of trimethylamine, raise the temperature, and keep the temperature at 60-65°C for 5h. Cool down to 40-45°C, slowly add 131kg of benzyl chloride into the reaction kettle, raise the temperature, keep the temperature at 70-85°C for 6 hours, and finally obtain colorless or light yellow tetradecyl with a content of 34%. Dicationic quaternary ammonium fungicide products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com