Production method for microbial balanced protein feed

A microbial balance and protein feed technology, applied in the field of compound feed production, can solve problems such as inefficient utilization and environmental damage, and achieve the effects of blocking invasion, improving digestibility, and improving health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

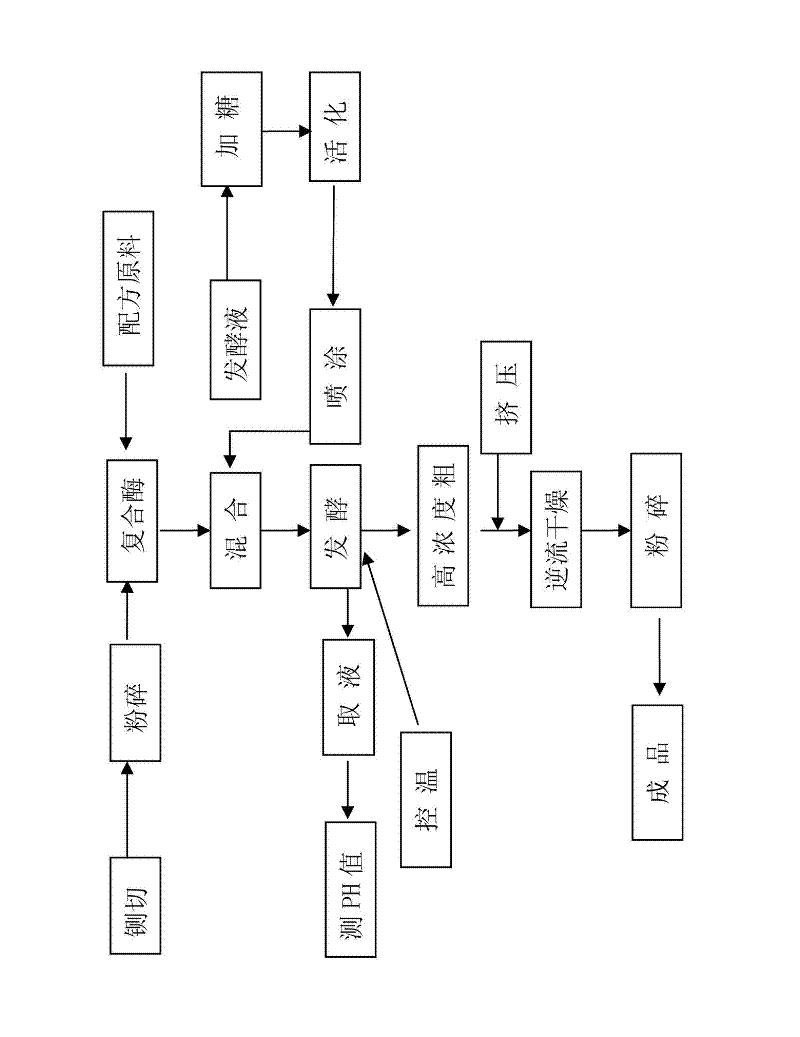

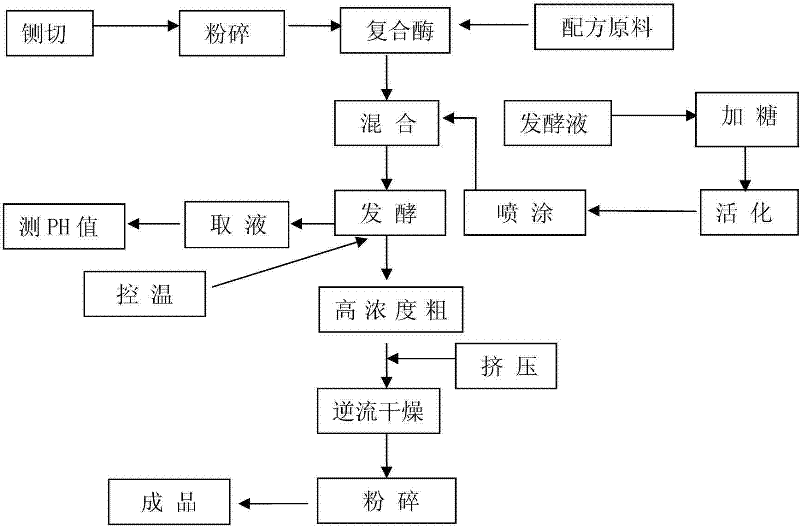

Image

Examples

Embodiment 1

[0053] Example 1 According to the percentage by weight, corn stalks with a moisture content of less than 15% were cut into 2 cm lengths and then crushed to 1.0 mm. Rice husks, rice bran, wheat bran and miscellaneous dregs were all crushed to 1.0 mm for later use. Straw powder 55%, rice husk powder 10%, rice bran or wheat bran 5%, miscellaneous dregs 18%, brown sugar 1.5%, and compound enzyme 0.05% were mixed with a twin-shaft paddle high-efficiency mixer for 100 seconds. Each batch is calculated as 1 ton, and 500ml of fermented liquid is put into 10kg of water for 2 hours of resurrection. Add 1.5kg of white sugar at a water temperature of 25°C, stir evenly, and then spray for 25 seconds through the liquid spraying equipment (spray the revived fermentation liquid evenly in the material). Then spray 300kg of clean water (using deep water well or purified water) and continue mixing for 80 seconds. Put it into a closed fermenter with the temperature controlled at 26°C. After 3 da...

Embodiment 2

[0064] Example 2 According to the percentage by weight, corn stalks with a moisture content of less than 15% were cut into 2 cm lengths and crushed to 1.0 mm. Rice husks, rice bran, wheat bran and miscellaneous dregs were all crushed to 1.0 mm for later use. Straw powder 65%, rice husk powder 15%, rice bran or wheat bran 10%, miscellaneous dregs 22%, brown sugar 2.5%, and compound enzyme 0.15% were mixed with a twin-shaft paddle high-efficiency mixer for 100 seconds. Each batch is calculated as 1 ton, and 500ml of fermented liquid is put into 10kg of water for 2 hours of resurrection. Add 2.5kg of sugar at a water temperature of 35°C, stir evenly, and then spray with liquid spray equipment for 25 seconds (spray the revived fermentation liquid evenly in the material). Then spray 300kg of clean water (using deep water well or purified water) and continue mixing for 100 seconds. Put it into a closed fermenter with the temperature controlled at 38°C. After 3 days, take the liquid...

Embodiment 3

[0065] Example 3 According to the percentage by weight, corn stalks with a water content of less than 15% were cut into 2 cm lengths and then crushed to 1.0 mm. Rice husks, rice bran, wheat bran and miscellaneous dregs were all crushed to 1.0 mm for later use. Straw powder 60%, rice husk powder 10%, rice bran or wheat bran 7%, miscellaneous dregs 20%, brown sugar 2.9%, and compound enzyme 0.10% were mixed with a twin-shaft paddle high-efficiency mixer for 100 seconds. Each batch is calculated as 1 ton, and 500ml of fermented liquid is put into 10kg of water for 2 hours of resurrection. Add 2.5kg of sugar at a water temperature of 35°C, stir evenly, and then spray with liquid spray equipment for 25 seconds (spray the revived fermentation liquid evenly in the material). Then spray 300kg of clean water (using deep water well or purified water) and continue mixing for 100 seconds. Put it in a closed fermenter with the temperature controlled at 38°C. After 3 days, take the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com