Manufacturing method for water cooled walls

A manufacturing method and water-cooled wall technology, applied in metal processing equipment and other directions, can solve the problems of difficult processing, non-dense casting structure, long production cycle, etc., and achieve the effect of reducing cutting allowance, avoiding casting defects, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, not to limit the scope of the present invention.

[0026] Such as Figure 1 to Figure 5 As shown, a method for manufacturing a water wall is characterized by including the following steps:

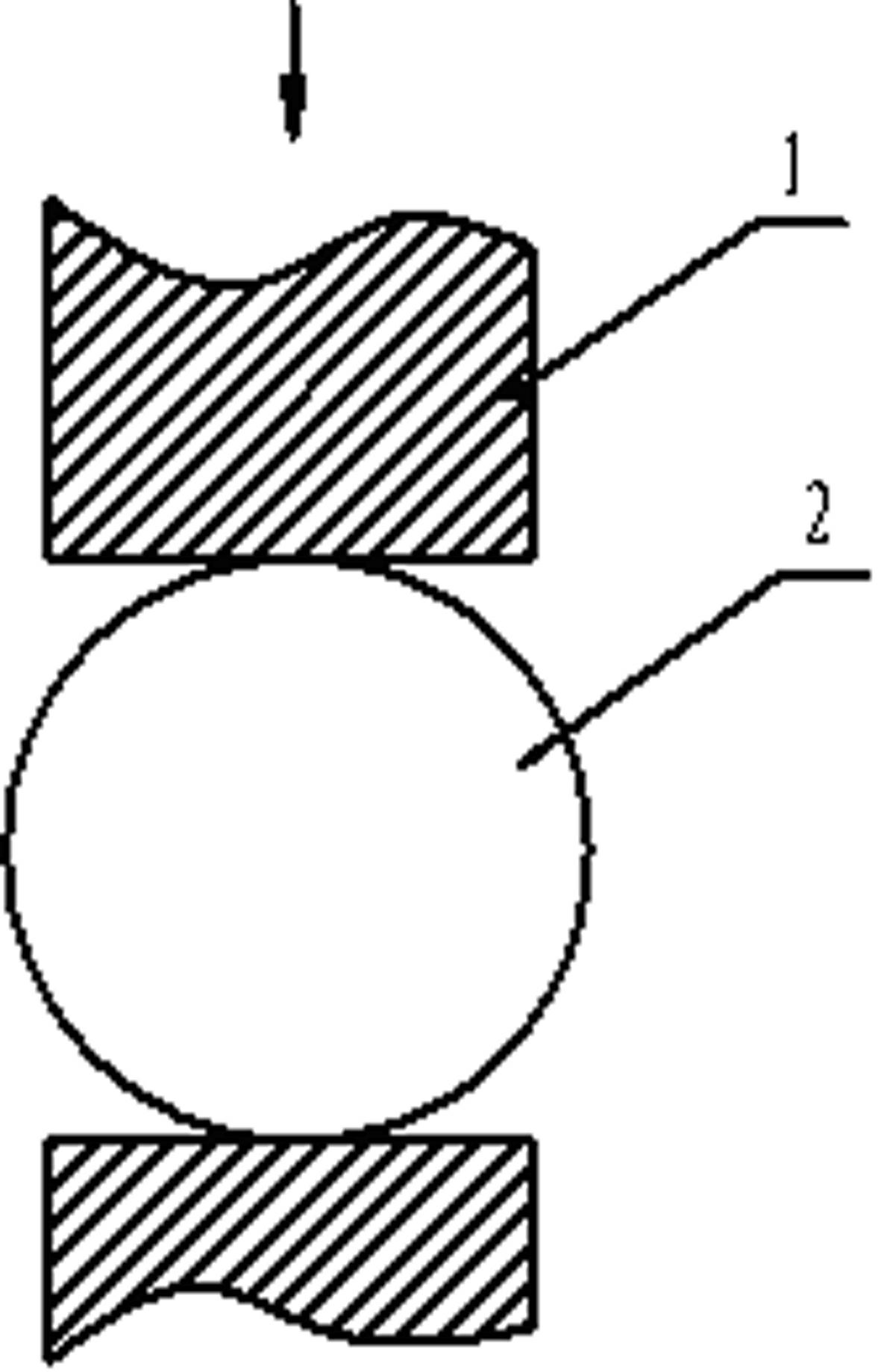

[0027] Step A: Melting and casting ingots: First, after melting the electrolytic copper, use a metal mold to cast into ingot 2. The weight of ingot 2 is calculated according to the finished size of the cooling stave, and the weight is usually 2-3 tons.

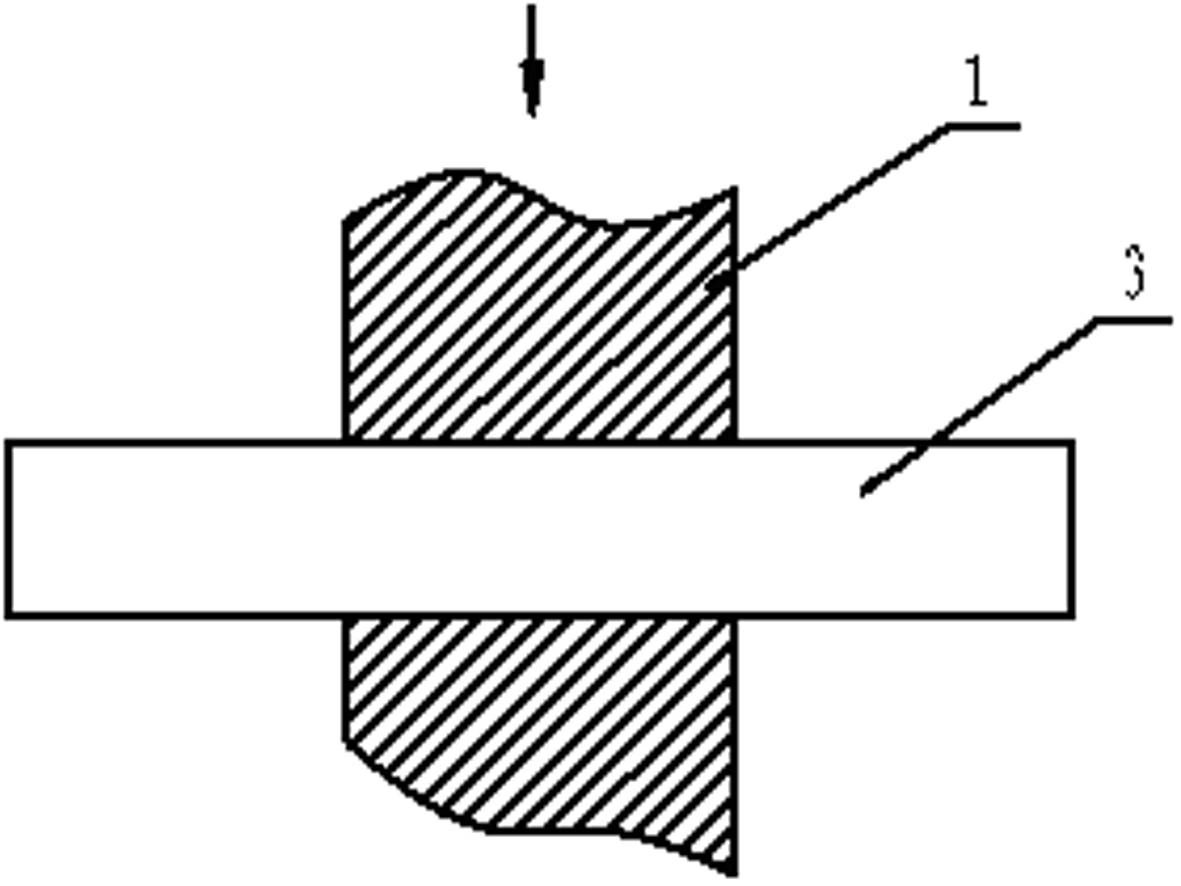

[0028] Step B: Forging the copper plate blank: Heat the ingot 2 produced in step A to 900℃±10℃, and use the forging plate anvil 1 to forge the blank and forge it into a copper plate blank 3 with a thickness of 95mm .

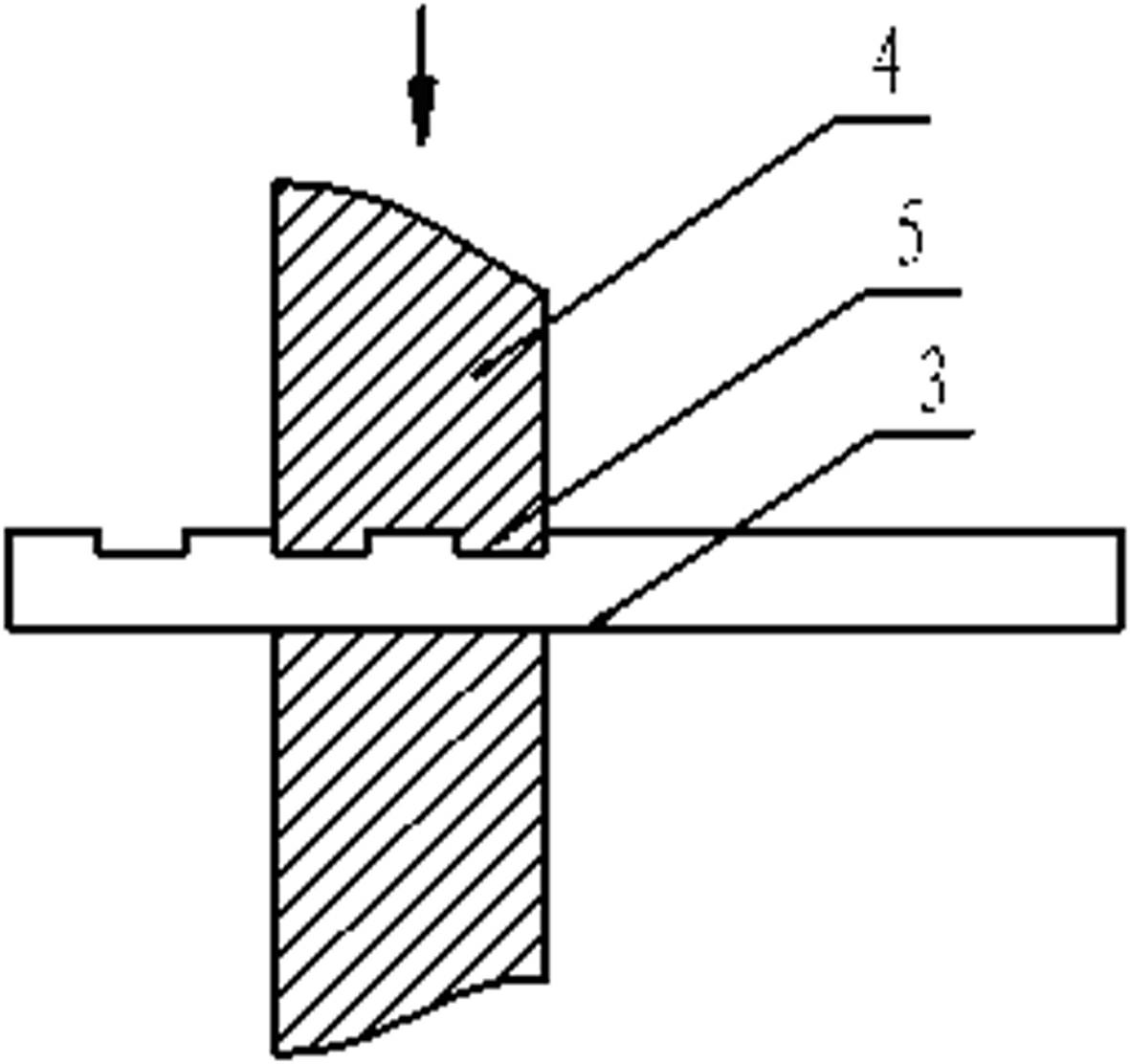

[0029] Step C: Forging groove: After heating the copper plate blank 3 produced in step B to 900℃±10℃ again, on the forging press equipped...

Embodiment 2

[0034] The copper plate blank 3 obtained according to steps A and B in Example 1 is then heated to 900°C±10°C, and the nozzle mounting hole 10 is punched with a forging press, and the nozzle mounting holes 10 are then processed according to C, D, and E in Example 1. , F proceed to obtain the finished water wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com