Method for preparing porous carbon microspheres converted from graphene

A technology of porous carbon and graphene, which is applied in the field of preparation of porous carbon microspheres, can solve the problems of high cost, complex process, difficult mass production and popularization and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

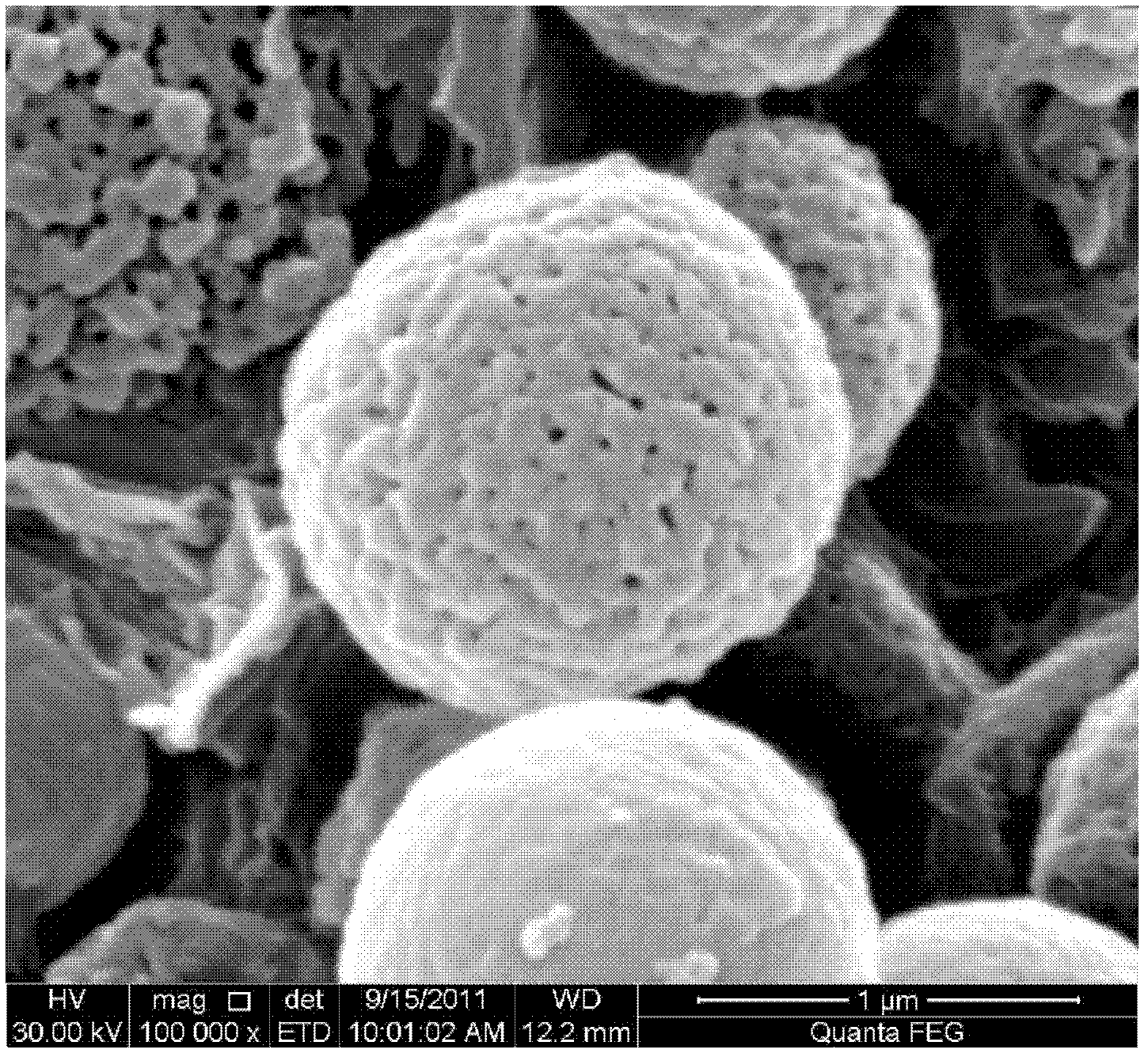

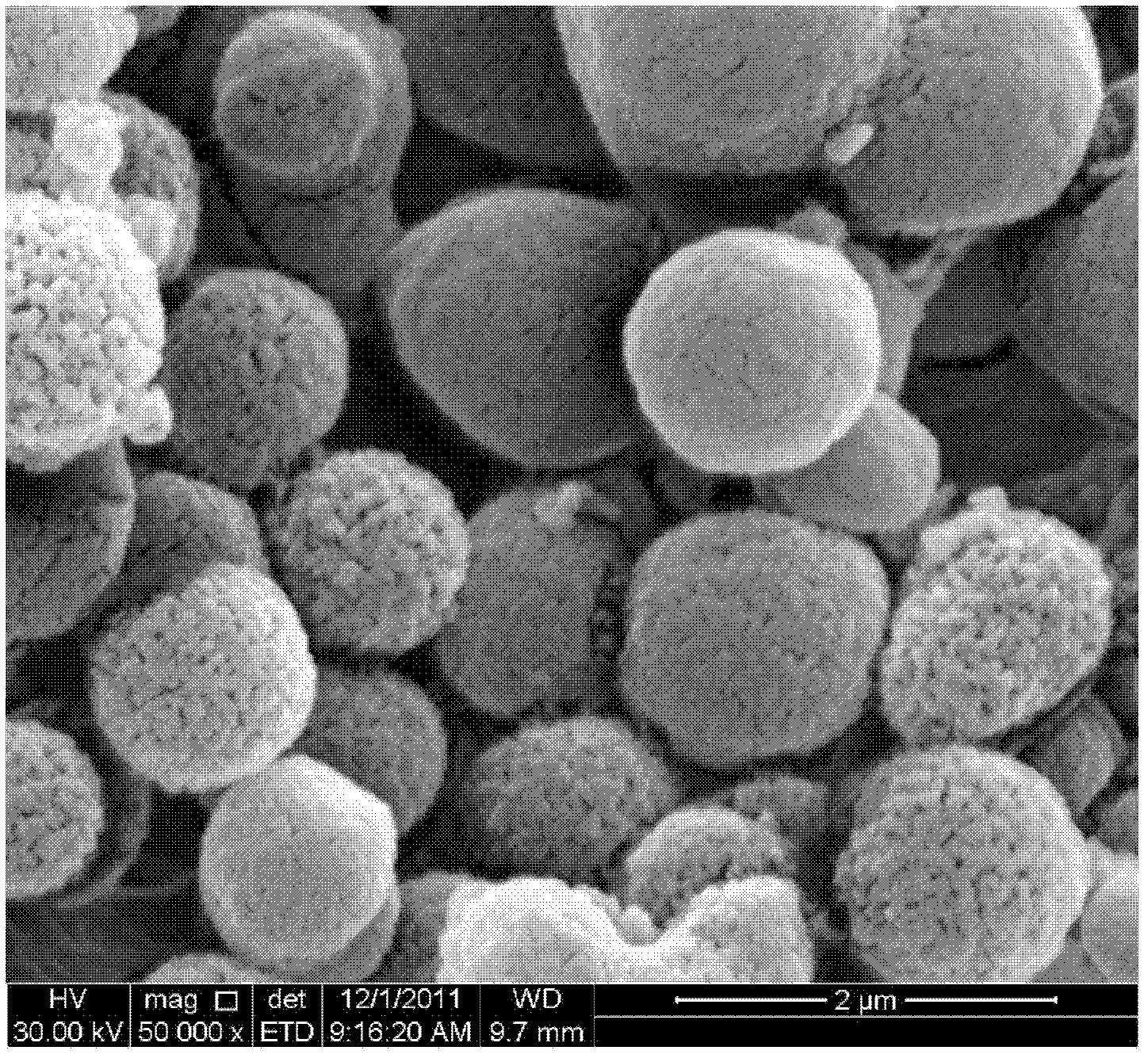

[0012] Embodiment 1: In this embodiment, the preparation method of graphene-converted porous carbon microspheres is carried out according to the following steps: adding graphite oxide into deionized water and ultrasonically exfoliating for 30-300 min to obtain a graphene oxide dispersion liquid, and then adding an initiator Mix well, the initiator is acid or alkali, the concentration of the initiator in the graphite oxide dispersion liquid is 0.01~5mol / L, and then placed in a steel reaction kettle with a polytetrafluoroethylene liner, sealed, and then at 100~5 mol / L Hydrothermal treatment at 250°C for 2 to 40 hours, naturally cooled to room temperature, washed with deionized water for 3 to 6 times, and dried to obtain porous carbon microspheres.

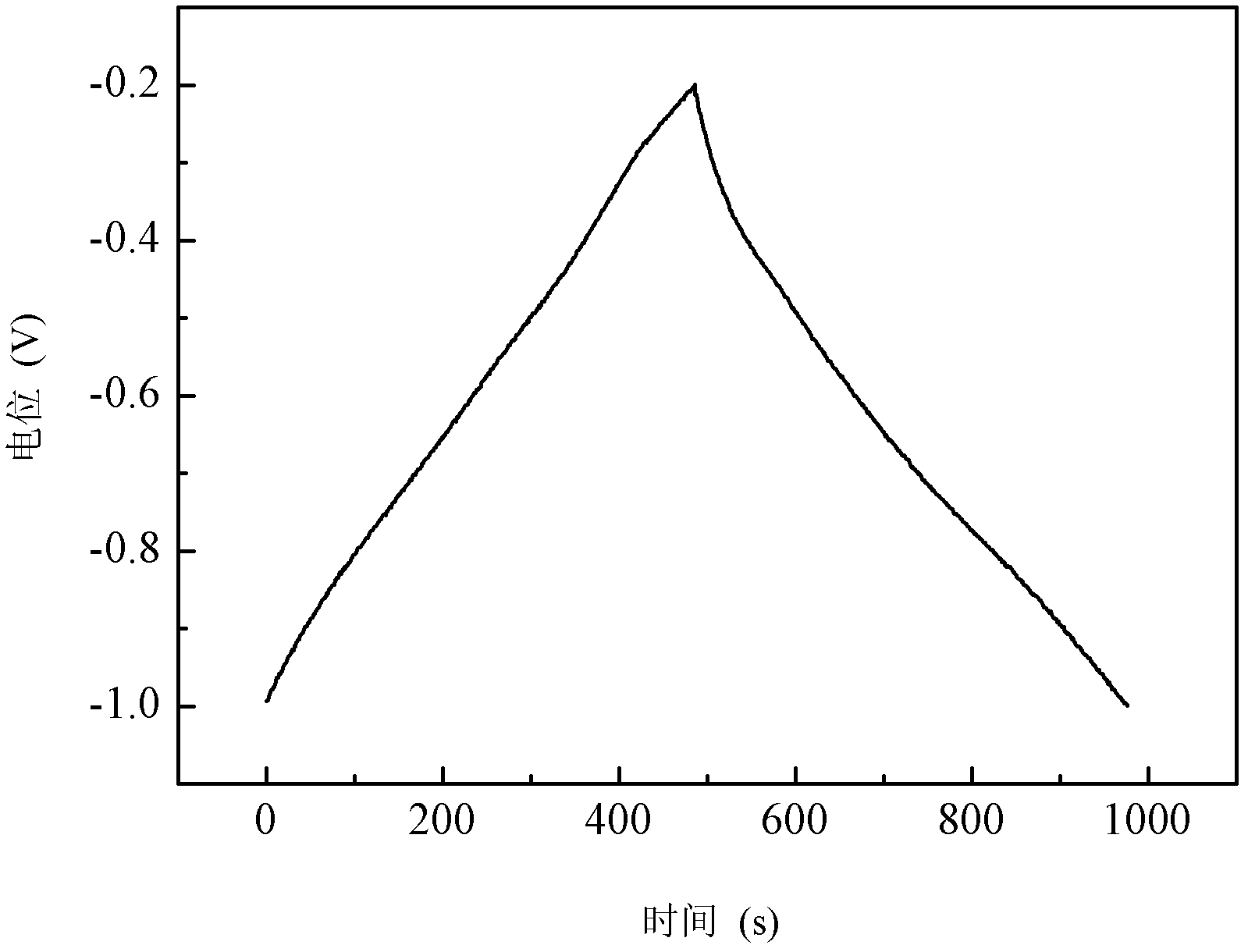

[0013] The diameter of the porous carbon microspheres is 0.5-3 μm, such as 600 nm, 1 μm, 2 μm or 2.5 μm. Specific capacity up to 306F·g -1 above.

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is: the graphite oxide is made from natural flake graphite, which is prepared by improving the hummers method (for the specific operation method, see: 1.N.I.Kovtyukhova, P.J.Ollivier, B.R.Martin, T.E.Mallouk, S.A.Chizhik, E.V.Buzaneva, |A.D.Gorchinskiy.Layer-by-Layer Assembly of Ultrathin Composite Films from Micron-Sized Graphite OxideSheets and Polycations|.Chem.Mater.1999,11,771-778.and 2 . W. S. Hummers, R. E. Offeman. Preparation of Graphical Oxide. J. Am. Chem. Soc. 1958, 80, 1339-1339.). Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the concentration of the graphene oxide dispersion liquid is 0.05-50 mg / ml. Other steps and parameters are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com