Energy-saving system applied to sludge treatment and disposal

An energy-saving system and sludge treatment technology, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/thickened sludge treatment, etc., can solve low heat utilization efficiency, heat waste, waste liquid discharge Major problems, to achieve the effect of improving the utilization rate of waste heat, reducing energy consumption and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with case the specific embodiment of the present invention is further described:

[0020] A sewage treatment plant has a daily sludge treatment volume of 75tDS / d, and the moisture content of the sludge at the inlet of the drying machine is 75%±3%, that is, the solid content rate is 25%±3%. It is required to increase the solid content of the sludge at the outlet of the drying machine to 90%, set up two production lines, and each production line can handle 150tWS / d of wet sludge. The sludge dryer adopts an indirect contact double-blade dryer. The drying heat medium uses hot steam, and a gas or biogas boiler is used to provide high-temperature steam.

[0021] Using the patent of the present invention to process the sludge drying waste steam in this case, the specific implementation method is as follows:

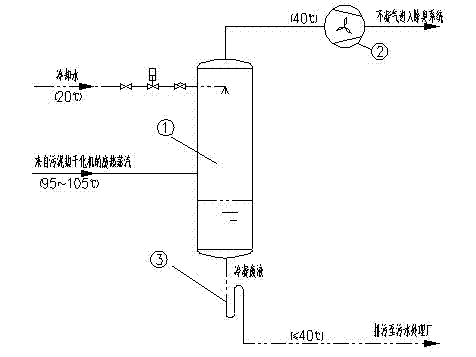

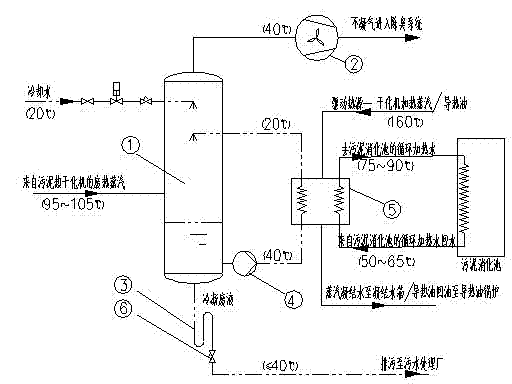

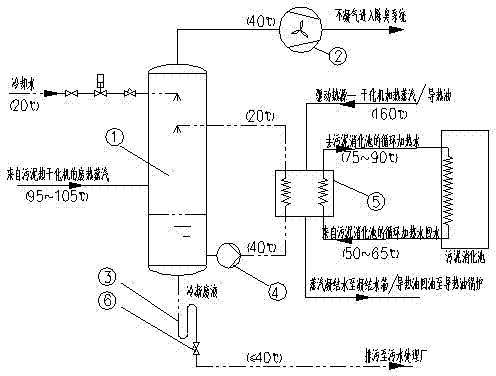

[0022] The temperature of the waste heat steam from the sludge thermal drying machine is about 95°C~100°C. Under the action of the process fan (2), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com