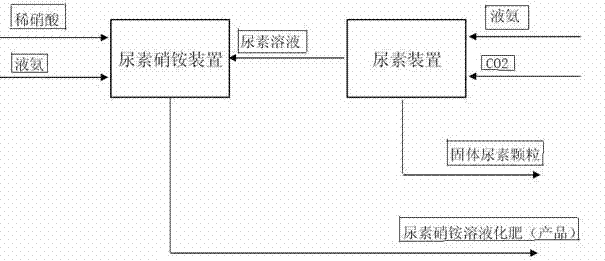

Preparation method for urea ammonium nitrate solution

A technology of urea ammonium nitrate and nitric acid solution, which is applied in the field of preparation of urea ammonium nitrate solution, can solve the problems of low fertilizer efficiency and achieve the effect of increasing yield and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

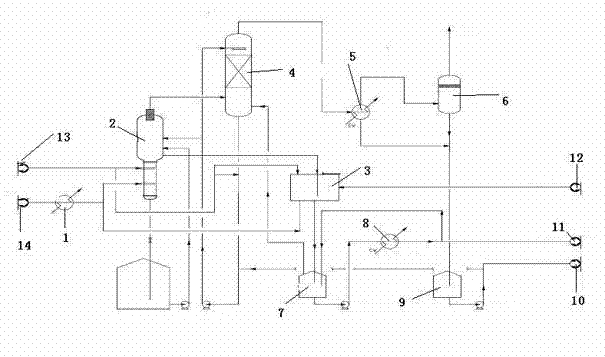

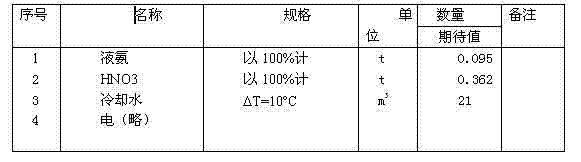

Embodiment 1

[0031] After the liquefied ammonia from the synthetic ammonia unit 13 is vaporized through the liquid ammonia evaporator 1, the nitric acid solution from the nitric acid unit 14 is neutralized in the first neutralizer 2 to generate ammonium nitrate, and the pH value is adjusted to 5. Ammonia: Nitric acid=1:1.2; the generated ammonium nitrate and the remaining ammonia gas in the reaction enter the separation section of the first neutralizer 2 for separation, ammonium nitrate enters the second neutralizer 3, and ammonia gas enters the washing system 4 for washing and recovery; The required urea solution raw material from the urea production unit 12; put ammonium nitrate: urea=1:1.23 in the second neutralizer (3) for reaction, adjust the pH value to 6.8, and generate urea ammonium nitrate solution; the generated urea The ammonium nitrate solution is cooled to 35 in the urea ammonium nitrate solution washing cooler 8 0 C, output 11; then the tail gas produced in the second neutral...

Embodiment 2

[0033] The liquid ammonia from the synthetic ammonia unit is vaporized through the liquid ammonia evaporator 1 and then neutralized with the nitric acid solution from the nitric acid unit in the first neutralizer 2 to generate ammonium nitrate, and the pH value is adjusted to 6. Ammonia: nitric acid = 1:1.1; the generated ammonium nitrate and the remaining ammonia gas in the reaction enter the separation section of the first neutralizer 2 for separation, ammonium nitrate enters the second neutralizer 3, and ammonia gas enters the washing system 4 for washing and recovery; prepare the required urea Solution raw material; put ammonium nitrate: urea=1:1.33 in the second neutralizer (3) for reaction, adjust the pH value to 7.5, and generate urea ammonium nitrate solution; wash the generated urea ammonium nitrate solution in urea ammonium nitrate solution Cooler 8 cool down to 45 0 C, storage 11; then the tail gas produced in the second neutralizer 3 enters the washing system for w...

example 3

[0035] The liquid ammonia from the synthetic ammonia unit is vaporized through the liquid ammonia evaporator 1 and then neutralized with the nitric acid solution from the nitric acid unit in the first neutralizer 2 to generate ammonium nitrate, and the pH value is adjusted to 5.5. Ammonia: nitric acid = 1:1.15; the generated ammonium nitrate and the remaining ammonia gas in the reaction enter the separation section of the first neutralizer 2 for separation, the ammonium nitrate enters the second neutralizer 3, and the ammonia gas enters the washing system 4 for washing and recovery; prepare the required urea Solution raw material; put ammonium nitrate: urea=1:1.28 in the second neutralizer (3) for reaction, adjust the pH value to 7, and generate urea ammonium nitrate solution; wash the generated urea ammonium nitrate solution in urea ammonium nitrate solution Cooler 8 to cool down to 40 0 C, storage 11; then the tail gas produced in the second neutralizer 3 enters the washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com