Lattice-type three-dimensional cell culture support and its manufacturing method and use method

A technology of three-dimensional cells and culture scaffolds, which is applied in tissue culture, biochemical equipment and methods, photolithography process exposure devices, etc. It can solve the problems of analyzing cell culture, affecting research and clinical application, pore size and distribution irregularity, etc. To achieve the effect of improving efficiency, low cost and reducing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

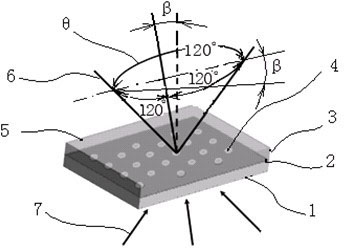

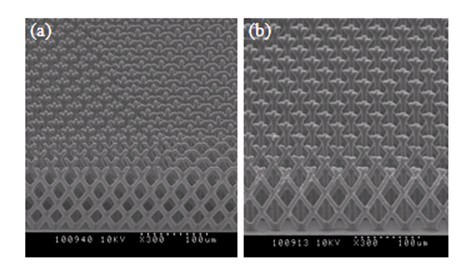

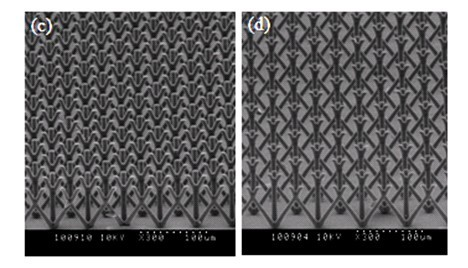

[0051] Such as figure 1 Shown is an embodiment of a lattice-shaped three-dimensional cell culture scaffold of the present invention. It includes a microporous quartz optical template; the microporous quartz optical template is made of a quartz optical template 5 with a film layer, and the micropores are an array of oblique columns; the quartz optical template 5 with a film layer is on the surface of the quartz optical template 1 After depositing the polymer material film layer 2 used as a sacrificial layer, an optical template of a layer of photosensitive adhesive layer 3 is attached; the oblique pillar array microhole 4 is a microhole made by back exposure 7 and oblique rotation exposure 6 . The ratio of depth to diameter of the oblique column sub-array microholes 4 is greater than or equal to 5 and less than or equal to 20, and 10 is selected in this embodiment. The polymer material film layer 2 of the sacrificial layer is made of water-soluble polymer material. The thickn...

Embodiment 2

[0053] Different from the above-mentioned embodiment 1, the ratio of the depth to the straight length of the oblique pillar sub-array microholes 4 is 5. The thickness of the photosensitive adhesive layer 3 is 50 microns. The photosensitive glue material of the photosensitive glue layer 3 is AZ photosensitive glue.

Embodiment 3

[0055] Different from the above-mentioned embodiment 1, the ratio of the depth to the straight length of the oblique column sub-array microholes 4 is 20. The thickness of the photosensitive adhesive layer 3 is 20 microns. The photosensitive adhesive material of the photosensitive adhesive layer 3 is PMMA photosensitive adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com