Method for producing alkaline protease

A production method and protease technology, applied in the field of microbial fermentation, can solve the problems of low utilization rate of raw materials, unfavorable enzyme production, difficult separation and purification, etc., and achieve the goal of reducing fermentation time, improving the ability of producing alkaline protease, and increasing the concentration of cells Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

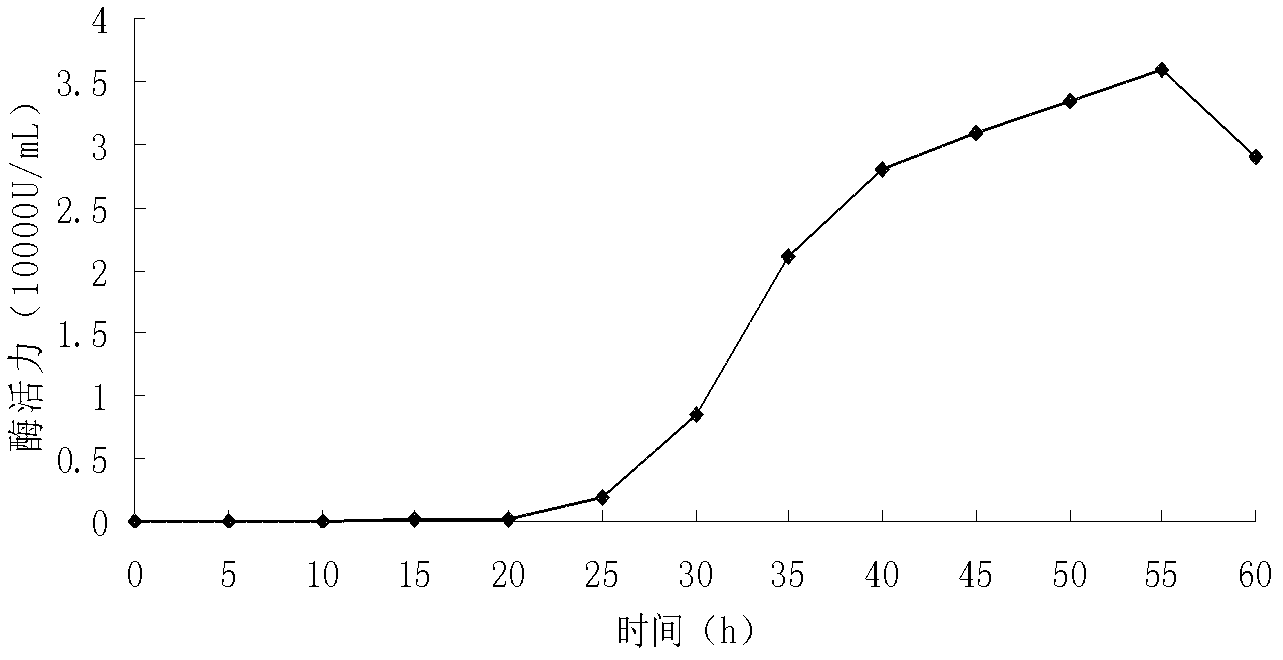

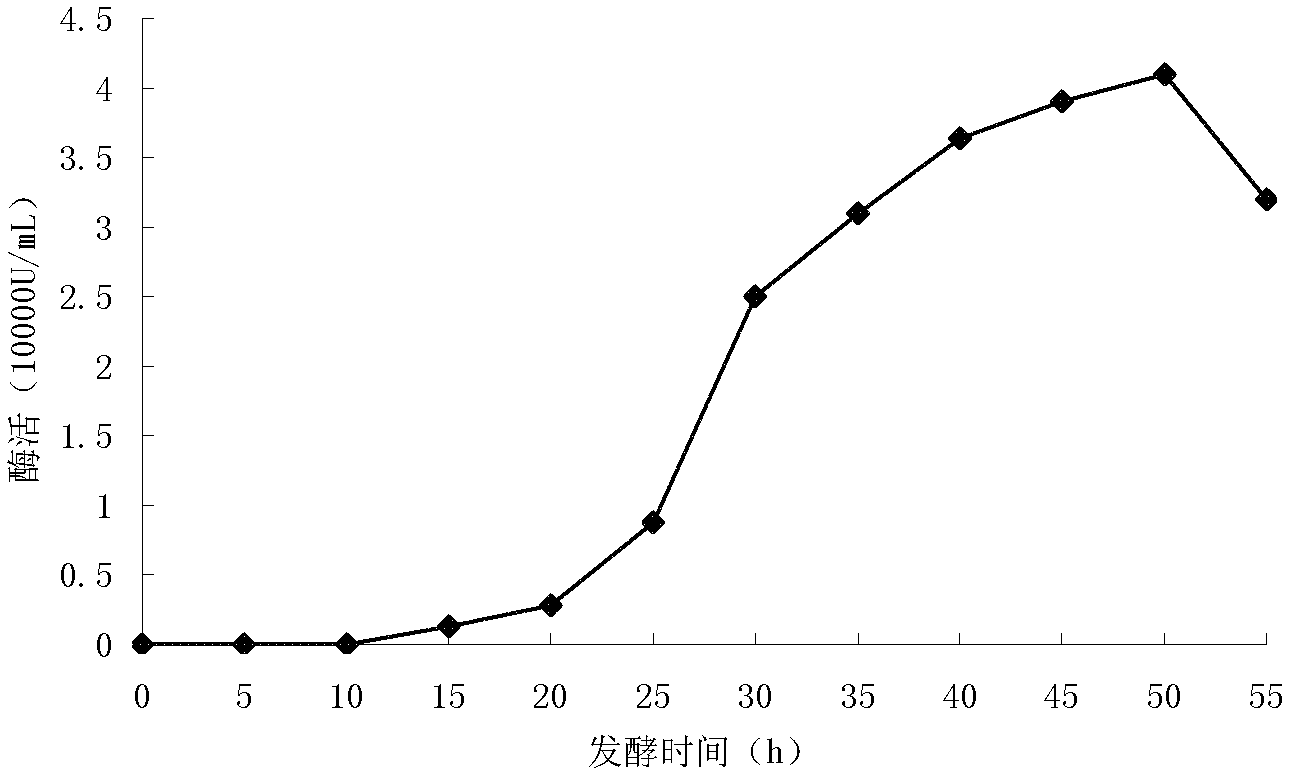

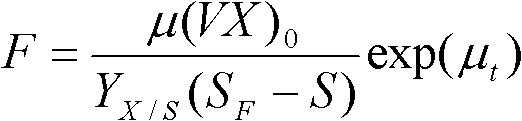

[0034] The present invention adopts fed-batch fermentation to reduce substrate inhibition, relieve substrate catabolite repression, reduce the formation of inhibitory by-products, and increase cell concentration; at the same time, the peak period of enzyme production is at the end of the logarithmic growth of the bacterium, and the carbon The concentration of nitrogen source becomes the limiting factor for the production of alkaline protease. Therefore, adding carbon and nitrogen sources and appropriately increasing the concentration of carbon and nitrogen sources in the fermentation broth can improve its enzyme production activity.

[0035] The present invention adopts the method of clear liquid fermentation at the same time, replaces the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com