Method for recovering tellurium copper from tellurium slag

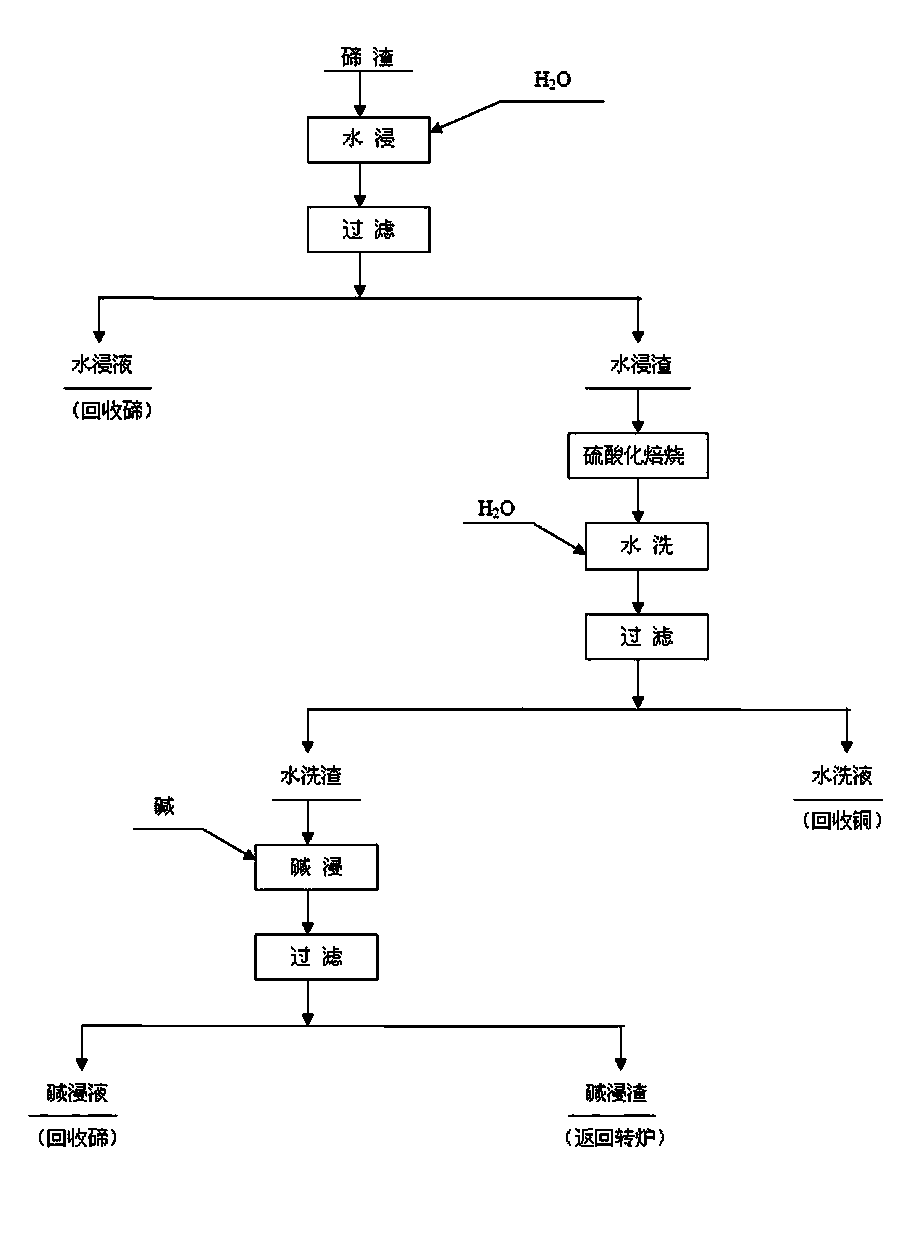

A technology of tellurium slag and water leaching, which is applied in the field of metallurgy, can solve the problems of non-leaching of copper, prolonging the recovery period, and low recovery rate, and achieves the effects of simple process, improved recovery rate, and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Take 200g of tellurium slag containing 12.4wt% Te and 7.31wt% Cu, grind it until the particle size is 100% below 80 mesh, add water (the mass ratio of water to tellurium slag is 5:1), and the leaching temperature is 90℃, Water immersion for 2 hours at a stirring speed of 300r / min; filter to obtain 1.2L of water immersion liquid and 210.7g of water immersion residue with 25% water content. The Te content in the water immersion solution is 13.43 g / L, and the Cu content is 0.05 g / L. The composition of Te and Cu in the dry slag obtained after drying the water immersion slag containing 25% water is as follows: 5.49wt% Te and 9.24wt% Cu. That is, during water immersion, the leaching rate of Te is 65%, and Cu is basically not leaching (the leaching rate of Cu is 0.41%).

[0044] (2) Take 200g of the water leached slag with 25% water content obtained in step (1), add 70mL of concentrated sulfuric acid and stir evenly (stirring speed is 100r / min), then transfer to a roastin...

Embodiment 2

[0048] (1) Take 200g of tellurium slag containing Te 15.51wt%, Cu 6.77wt%, grind it until the particle size is 100% below 80 mesh, add water (the mass ratio of water to tellurium slag is 3:1), and the leaching temperature is 90°C, Water immersion for 3 hours at a stirring speed of 250r / min; filter to obtain 850mL of water immersion liquid and 205.6g of water immersion residue with 25% water content. The Te content in the water immersion solution is 24.82g / L, and the Cu content is 0.062g / L. The composition of Te and Cu in the dry slag obtained after drying the water-leached slag with 25% water content is as follows: 6.77wt% Te and 8.75% Cu. That is, during water immersion, the leaching rate of Te is 68%, and Cu is basically not leaching (the leaching rate of Cu is 0.39%).

[0049] (2) Take 200g of the 25% water leaching slag obtained in step (1), add 65mL of concentrated sulfuric acid and stir evenly (stirring speed is 150r / min), then transfer to a roasting furnace with a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com