PLC controller specially used by functionalized knitted fabric equipment with nanofiber surface coating

A nanofiber, surface coating technology, applied in the direction of comprehensive factory control, program control in sequence/logic controller, fiber processing, etc. low intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

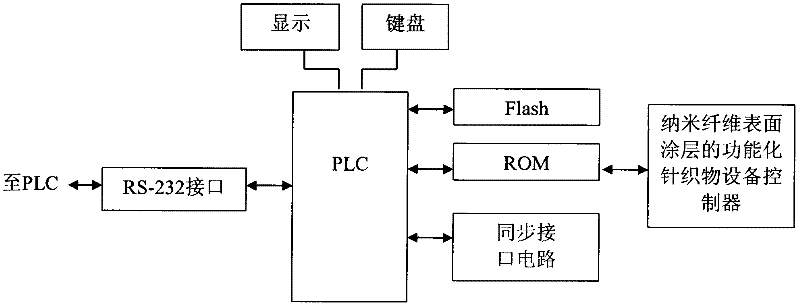

[0024] The whole nano-coating equipment controller is mainly composed of PLC system, and its processor is mainly composed of PLC, memory, communication interface and keyboard display, etc., which are used to receive, store and process process data during the working process. The composition block diagram is as follows image 3 shown. When changing the process, use the system microcomputer to input process data through the RS232 interface and store it in the process processor.

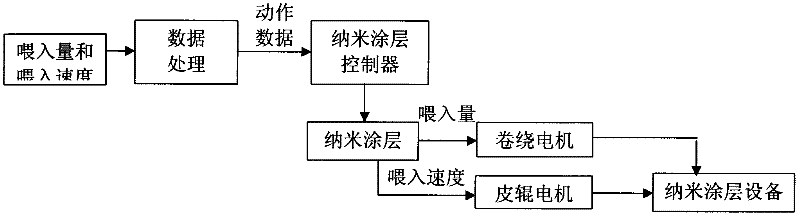

[0025] The whole nano-coating controller is mainly composed of PLC system, process processor, synchronous signal generation circuit, feeding stepper motor drive circuit, main motor speed control circuit, start, stop and fault self-stop interface circuit, keyboard display circuit, etc. The block diagram of the circuit is as Figure 4 shown. Process memory is used to store process data, using AM29F016D flash memory with a capacity of 1.5M bytes, keyboard and display are used to input manual process and ...

Embodiment 2

[0028] The whole nano-coating equipment is mainly controlled by the PLC system, and the process processor is mainly composed of a single-chip microcomputer, a storage body, a communication interface and a keyboard display, etc., which are used to receive, store and process process data during the work process. The composition block diagram is as follows Figure 5 shown. When changing the process, store the processed process data into the U disk, and read the process data of the U disk into the memory of the process processor through the USB interface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com