Preparation method of novel heat isolating nanometer material

A technology of nano-materials and nano-composites, which is applied in the field of preparation of new heat-insulating nano-composites, can solve the problems of poor high-temperature resistance of heat-insulating materials, limit the application of heat-insulating materials, and reduce the heat-insulation performance of heat-insulating materials, etc. Cross-linking degree, improvement of heat insulation effect, effect of lowering thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

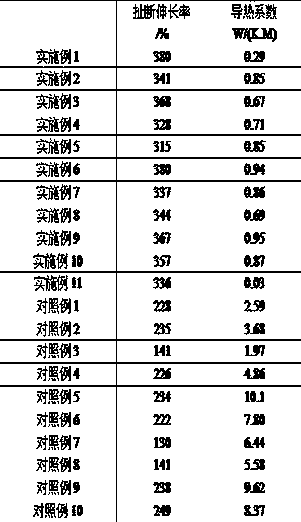

Examples

Embodiment 1

[0016] A method for preparing a novel heat-insulating nanomaterial, the method comprising the following steps:

[0017] Step 1, 36 parts of Cu-BTC-SiO 2 Nanomaterials, 12 parts of polyethylene resin, 3 parts of polycarbonate, 6 parts of barium stearate and 5 parts of glass fiber are mixed and stirred in a mixer to form a mixed slurry;

[0018] Step 2. Transfer the above slurry to a reaction kettle, heat to 80°C under the protection of argon, add 8 parts of ethyl methacrylate and 3 parts of ethylene oxide, stir for 30 minutes, and then heat up to 75°C. Add 5 parts of alumina, continue to stir for 60 minutes, and obtain the green body material after drying;

[0019] Step 3. Neatly put the green body material prepared in the above steps into the mold, then put the mold into the molding press for one-time molding and pressing, and then perform pressure curing. The curing temperature is from room temperature to 175°C, and the curing time is 3 Hour;

[0020] Step 4. Put the solid...

Embodiment 2

[0027] Step 1, 26 parts of Cu-BTC-SiO 2 Nanomaterials, 22 parts of polyethylene resin, 3 parts of polycarbonate, 6 parts of barium stearate and 5 parts of glass fiber are mixed and stirred in a mixer to form a mixed slurry;

[0028] Step 2. Transfer the above slurry to a reaction kettle, heat to 80°C under the protection of argon, add 8 parts of ethyl methacrylate and 3 parts of ethylene oxide, stir for 30 minutes, and then heat up to 75°C. Add 5 parts of alumina, continue to stir for 60 minutes, and obtain the green body material after drying; the rest of the preparation is the same as in Example 1.

Embodiment 3

[0030] Step 1, 19 parts of Cu-BTC-SiO 2 Nanomaterials, 14 parts of polyethylene resin, 3 parts of polycarbonate, 6 parts of barium stearate and 5 parts of glass fiber are mixed and stirred in a mixer to form a mixed slurry;

[0031] Step 2. Transfer the above slurry to a reaction kettle, heat to 80°C under the protection of argon, add 8 parts of ethyl methacrylate and 3 parts of ethylene oxide, stir for 30 minutes, and then heat up to 75°C. Add 5 parts of alumina, continue to stir for 60 minutes, and obtain the green body material after drying; the rest of the preparation is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com