Preparation method and application of massive titanium-based aerogel

An airgel and block technology, applied in the field of porous materials, can solve the problems of difficult drying process, low strength of finished products, difficulty in recycling, etc., achieve good application prospects, simple preparation process, and overcome the effect of low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

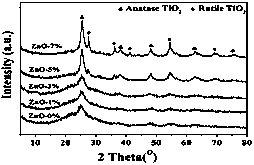

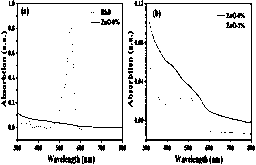

[0029] A titanium dioxide airgel material used for photocatalytic degradation of Rhodamine B under visible light, in which the airgel is doped with zinc oxide, and the gel skeleton is strengthened with silicon dioxide.

[0030] A preparation method of bulk titanium-based airgel, the specific preparation steps are as follows:

[0031] 1) Dissolve 3.333g of zinc acetate in 20ml of deionized water to prepare a zinc acetate solution with a concentration of 0.76mol / L;

[0032] 2) Stir and mix butyl titanate, EtOH, and anhydrous acetic acid in a molar ratio of 1:10.5:0.5 according to a certain molar ratio to obtain solution A; anhydrous acetic acid, EtOH, and deionized water in a molar ratio of 2.0:10.5 : 4 Stir and mix evenly to prepare solution B; under vigorous stirring, according to the volume ratio A:B=1.25:1, add solution B to solution A at a rate of 50 drops / min; after stirring for 30min, press titanic acid Butyl ester, formamide molar ratio 1:0.8 add formamide, stir evenly,...

Embodiment 2

[0039]A titanium dioxide airgel material used for photocatalytic degradation of Rhodamine B under visible light, in which the airgel is doped with zinc oxide, and the gel skeleton is strengthened with silicon dioxide.

[0040] A preparation method of bulk titanium-based airgel, the specific preparation steps are as follows:

[0041] 1) Dissolve 3.333g of zinc acetate in 20ml of deionized water to prepare a zinc acetate solution with a concentration of 0.76mol / L;

[0042] 2) Stir and mix butyl titanate, EtOH, and anhydrous acetic acid in a molar ratio of 1:12.5:0.6 in a certain molar ratio to obtain solution A; anhydrous acetic acid, EtOH, and deionized water in a molar ratio of 2.4:10: 4 Stir and mix evenly to prepare solution B; under vigorous stirring conditions, according to the volume ratio A:B=1.25:1, add solution B to solution A at a rate of 60 drops / min; Ester, formamide molar ratio 1:0.9 Add formamide, stir evenly, obtain titanium dioxide sol;

[0043] 3) Under stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com