ZnO substrate epitaxy structure, manufacture method thereof and ZnO substrate chip structure

A technology of epitaxial structure and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as blue light spot, low light extraction efficiency, yellow phosphor coating thickness, yellow aperture, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

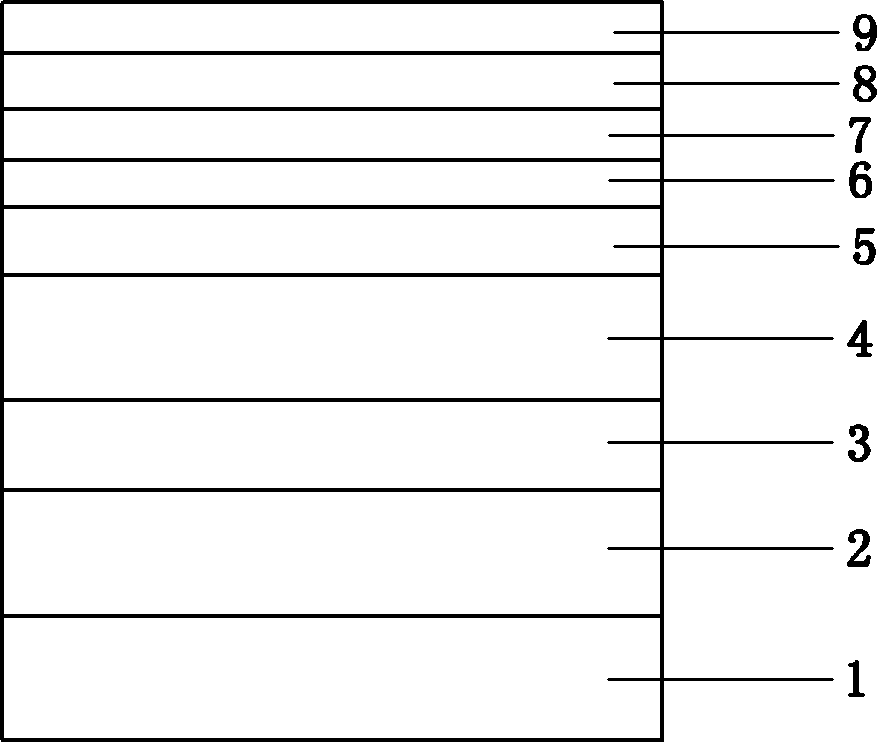

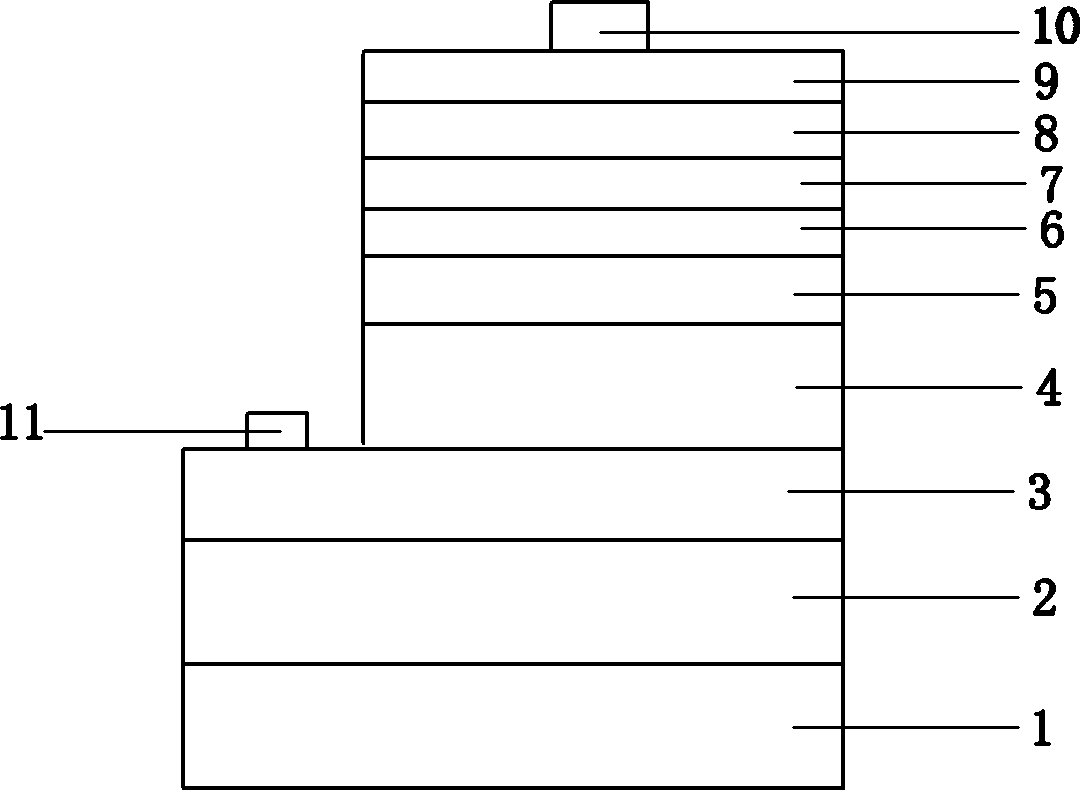

[0028] Such as figure 1 As shown, a ZnO substrate epitaxial structure includes an epitaxial wafer, and the epitaxial wafer includes a ZnO substrate 1, a GaN transition layer 2, a first N-GaN contact layer 3, doped Si and Zn In 0.2 Ga 0.8 N / GaN multi-quantum well light-emitting layer 4, first P-GaN contact layer 5, N-GaN cascade layer 6, second N-GaN contact layer 7, In doped with Si and Zn 0.49 Ga 0.51 N / GaN multi-quantum well light-emitting layer 8 and the second P-GaN contact layer 9 . ZnO substrate is a nanoscale material with wide energy band gap, high refractive index, high light transmittance, and has excellent fluorescence effect and electroluminescent function.

[0029] Wherein, the thickness of the ZnO substrate 1 is 50-200um, preferably 100um.

[0030] Wherein, the thickness of the GaN transition layer 2 is 10-100 nm, preferably 50 nm.

[0031] Wherein, the thicknesses of the first N-GaN contact layer 3 and the second N-GaN contact layer 7 are both 200-1000 nm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com