Composite microbial fermented soybean hull feed and preparation method thereof

A technology of compound microorganisms and soybean hulls, which is applied in the field of aquaculture feed, can solve the problems of increasing the complexity of feed preparation process, feed aflatoxin pollution, and increasing feed cost, so as to shorten the feeding period, improve meat and milk quality, increase Effects of meat mass and milk production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Raw material ratio of compound microbial fermented soybean hulls feed: soybean hulls 800 kg, soybean meal 200 kg, molasses 10-20 kg, yeast (content: yeast ≥ 200 million / g) 2-2.5 kg, lactic acid bacteria (content: Lactic acid bacteria ≥ 300 million / g) 1-3 kg, Bacillus (content: Bacillus ≥ 300 million / g) 1.5-3.5 kg, bifidobacteria (content: Bifidobacterium ≥ 200 million / g) 2-3 Kilogram.

Embodiment 2

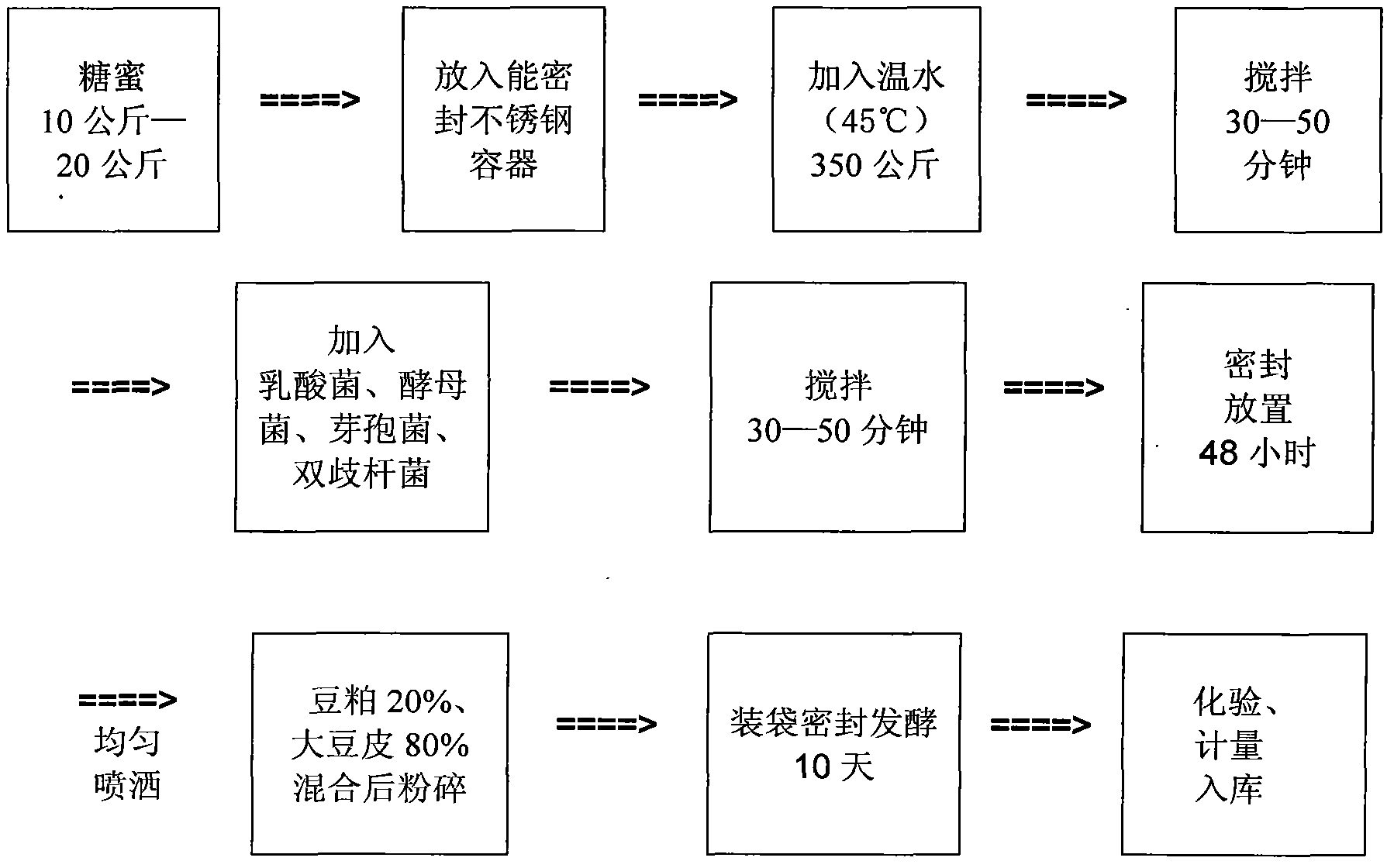

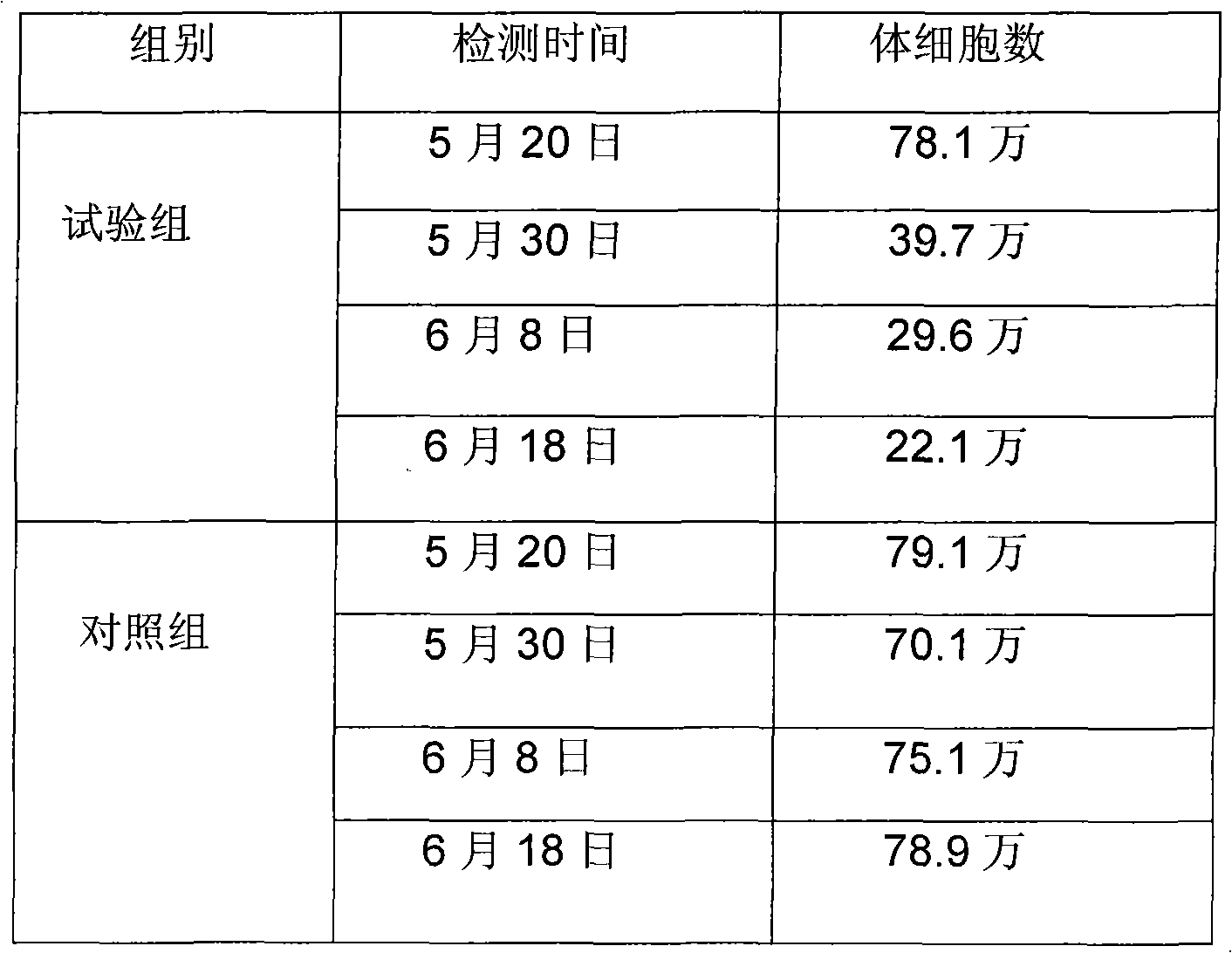

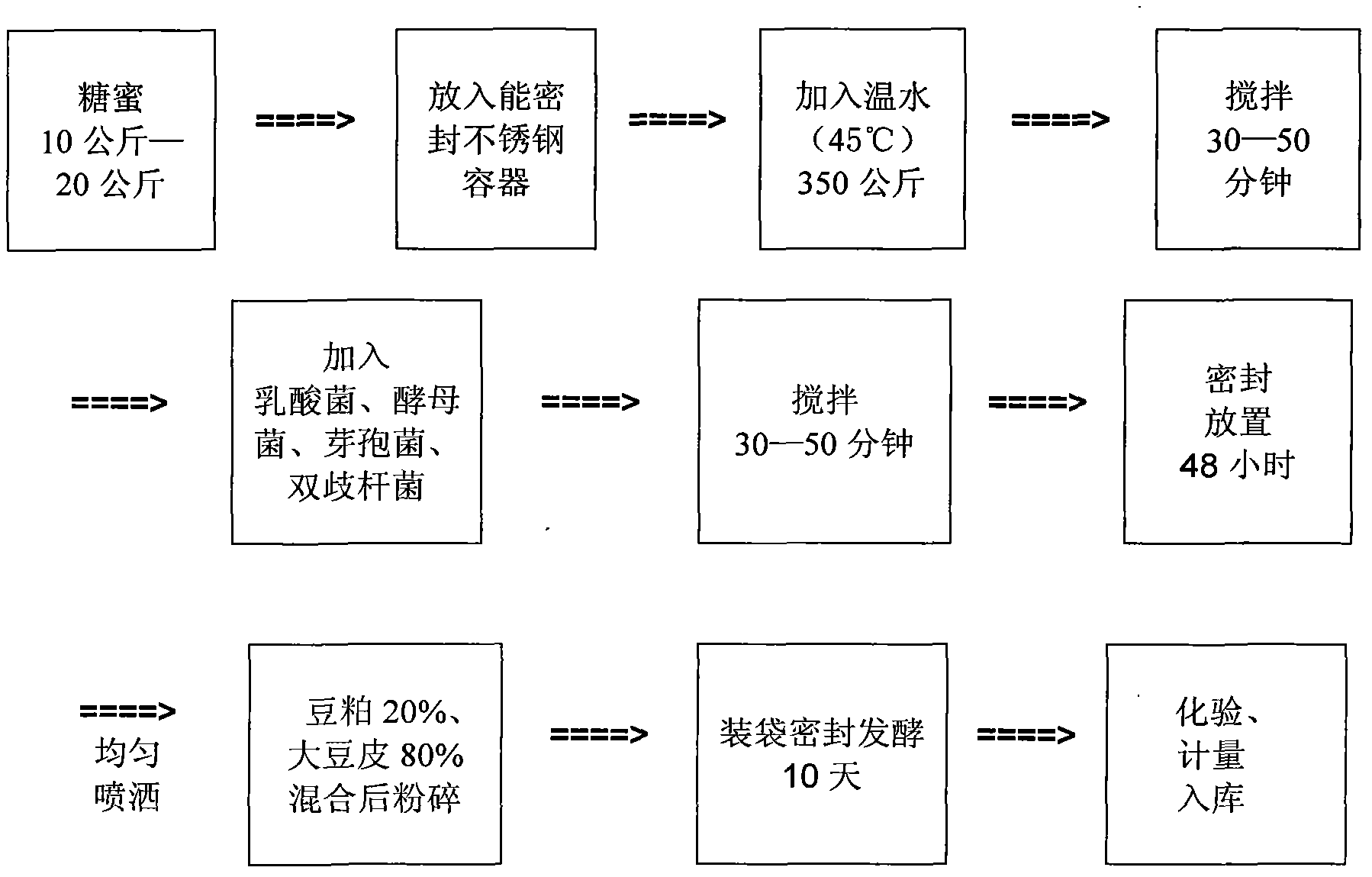

[0025] The method of preparing compound microbial fermented soybean hull feed: (1) Put 10-20 kg of molasses in a stainless steel bucket of about 500 kg, add 45°C warm water to dissolve evenly and stir for 30 minutes, then add 2-2.5 kg of yeast, 1-3 kg of lactic acid bacteria, 1.5-3.5 kg of bacillus, 2-3 kg of bifidobacteria, stirred evenly for 30-50 minutes, sealed and placed for 48 hours for later use, during which the temperature of the stainless steel bucket should be kept between 25-45 ° C. (2) Evenly pulverize 200 kg of soybean meal and 800 kg of soybean skin to 40-80 mesh to make a mixture of meal and skin; (3) Spray the mixed bacteria liquid evenly in the mixture of meal and skin, and control the moisture at About 45-55%, packed into biological feed packaging bags, 25 or 40 kg per bag, put into the greenhouse for fermentation. (4) The fermentation temperature is controlled at 20-30°C from day 1 to day 4, controlled at about 45°C from day 5 to day 8, and controlled at ab...

Embodiment 3

[0027] The soybean hulls fermented by complex microorganisms are prepared by using crushed soybean feed instead of the above soybean hulls. Soybean crushed feed consists of soybean hulls and processed soybean flour and scraps at the end of the grinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com