Preparation method of extracts of effective fractions of lychee seeds

A technology of effective parts and lychee pits is applied in the field of preparation of extracts from effective parts of traditional Chinese medicine lychee pits, which can solve the problems of unmentioned extraction and the like, and achieve the effects of complete extraction, clear composition and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Crush the lychee pits into a coarse powder. Take 100g of lychee seed powder, add 1000ml of 70v / v% ethanol for the first time, soak for 0.5 hours, then ultrasonically extract for 1 hour, pour the extract A into the container for later use. Continue to add 800ml of 70v / v% ethanol to the medicinal residues, after soaking for 1 hour, ultrasonically extract for 1 hour, pour out the extract B, and combine it with the extract A obtained by the first extraction. The combined extract A and extract B are recovered to ethanol until there is no alcohol smell. The recovery method is preferably vacuum distillation recovery (vacuum degree -0.1MPa, temperature 75°C). The medicinal solution after recovery of ethanol was diluted with distilled water to 250ml, left standing overnight, filtered, and the filtrate was set aside. The filtrate first passes through the treated AB-8 macroporous resin column at a flow rate of 2 times the column bed volume per hour (see below for the treatment m...

Embodiment 2

[0032] Crush the lychee pits into a coarse powder. Take 100g of lychee seed powder, add 800ml of 70v / v% ethanol for the first time, soak for 1 hour, ultrasonically extract for 1 hour, and pour the extract A into the container for later use. Continue to add 1000ml of 70v / v% ethanol to the dregs, soak for 0.5 hours, ultrasonically extract for 1 hour, pour out the extract B, and combine it with the extract A obtained by the first extraction. The combined extract A and extract B are recovered to ethanol until there is no alcohol smell. The recovery method is preferably vacuum distillation recovery (vacuum degree -0.1MPa, temperature 75°C). The medicinal solution after recovery of ethanol was diluted with distilled water to 250ml, left standing overnight, filtered, and the filtrate was set aside. The filtrate first passed through the treated AB-8 macroporous resin column at a flow rate of 2 times the column bed volume per hour, then eluted with pure water of 3 times the amount of...

Embodiment 3

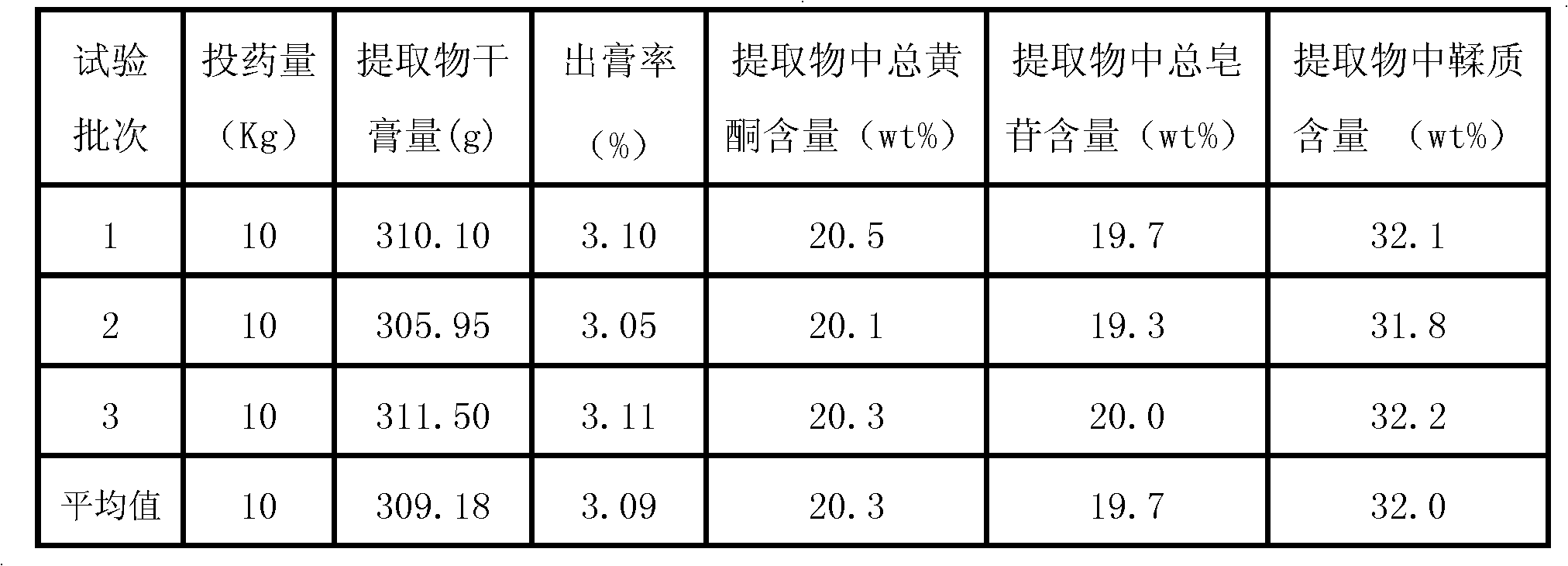

[0035] Example 3 Pilot Scale-Up Test

[0036] Weigh 10Kg of lychee kernel coarse powder, add 100L of 70v / v% ethanol for the first time, soak for 0.5 hours, then ultrasonically extract for 1 hour, and pour the extract into a container for later use. Continue to add 80L of 70v / v% ethanol to the dregs, soak for 0.5 hours, ultrasonically extract for 1 hour, pour out the extract and combine it with the first extract; depressurize the combined total extract to recover ethanol until it has no alcohol smell (vacuum degree -0.1MPa, temperature 75°C), the extract was diluted with distilled water to a volume of 25L, left to stand overnight, filtered, and the filtrate was set aside. The filtrate first passed through the treated AB-8 macroporous resin column at a flow rate of 2 times the column bed volume per hour, then eluted with 3 times the resin amount of pure water at a flow rate of 2 times the column bed volume per hour, and discarded the water for washing liquid, then elute the eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com